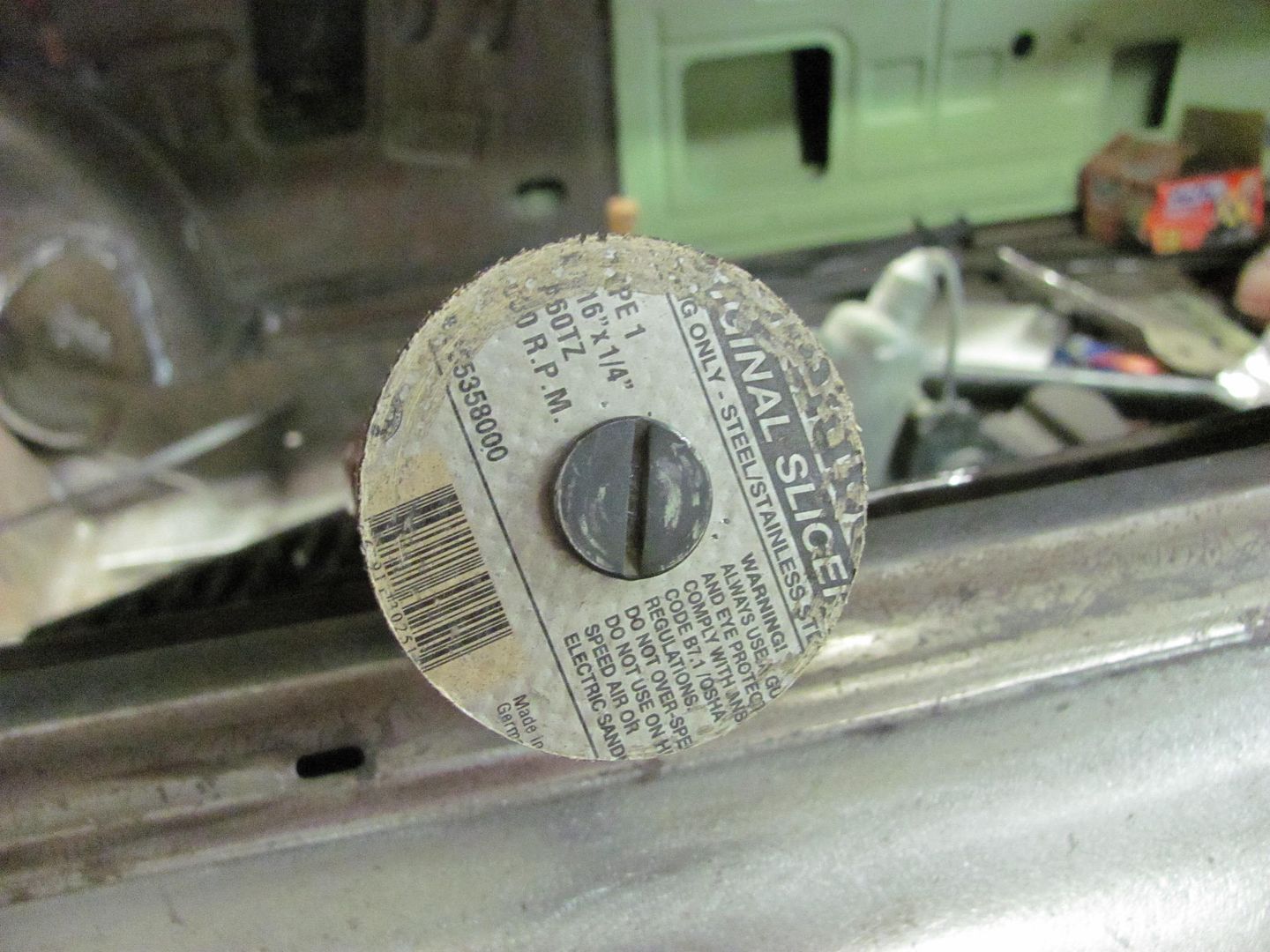

Doesn't look like I've done much here, but got more grinding done on the quarter panel seams, a little over 6' of weld length done. Here's where the stainless rated cutoff wheels work so well. When I was using the cheap discs (the brown cloud makers) this much weld would have taken well over two discs to grind, and an air hose to clean up before walking back in the house. One stainless rated disc did this amount, and diameter went from 3" to 2-1/2, so still have quite a bit left in it..

new disc

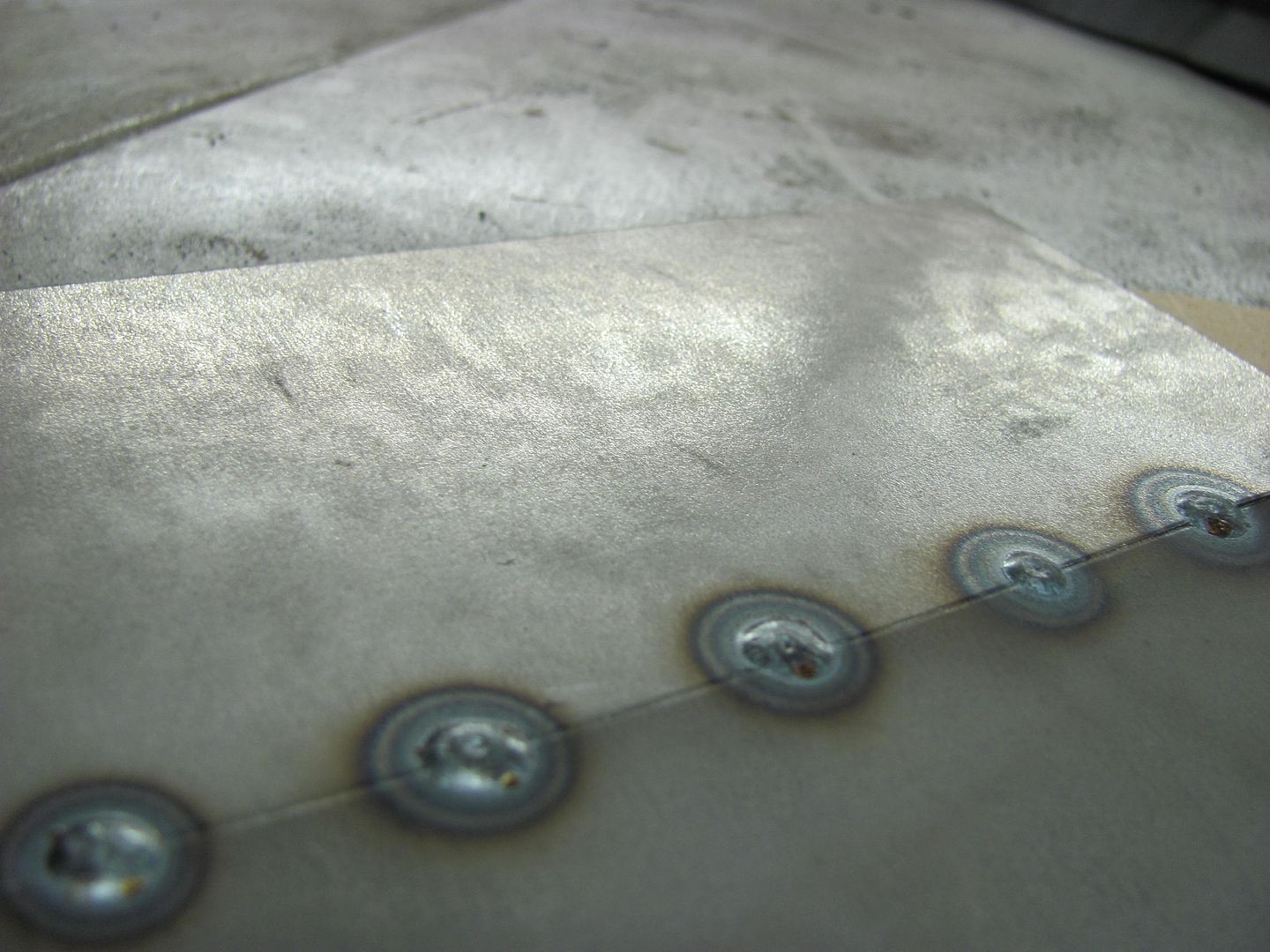

after tonight's grinding

So despite how appealing those cheap cutoff wheels may be to those on a tight budget, cheap ain't always cheap. The stainless rated wheels are the only ones I buy anymore, money ahead.

Here's the weld grinding process...

Reply With Quote

Reply With Quote