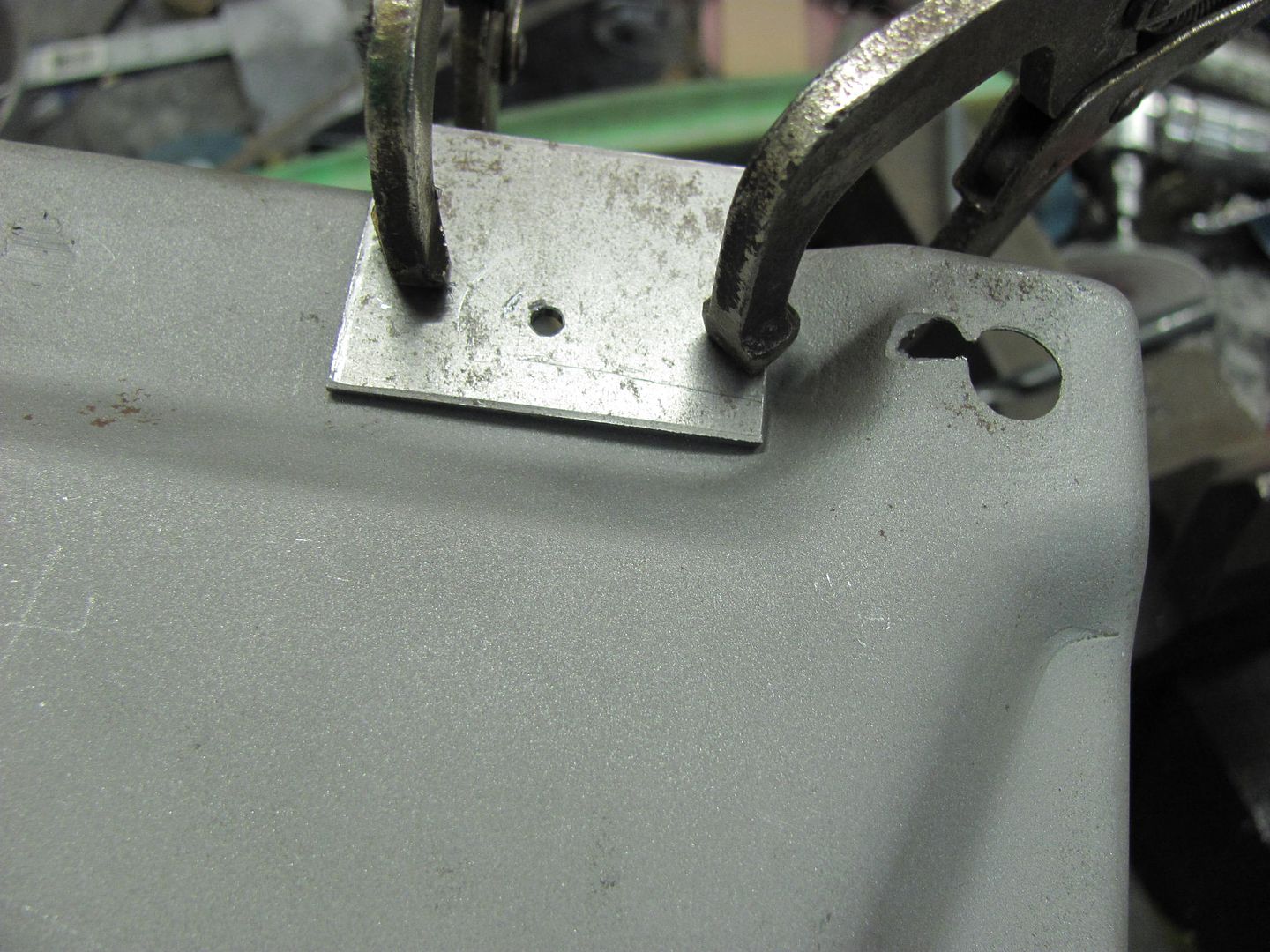

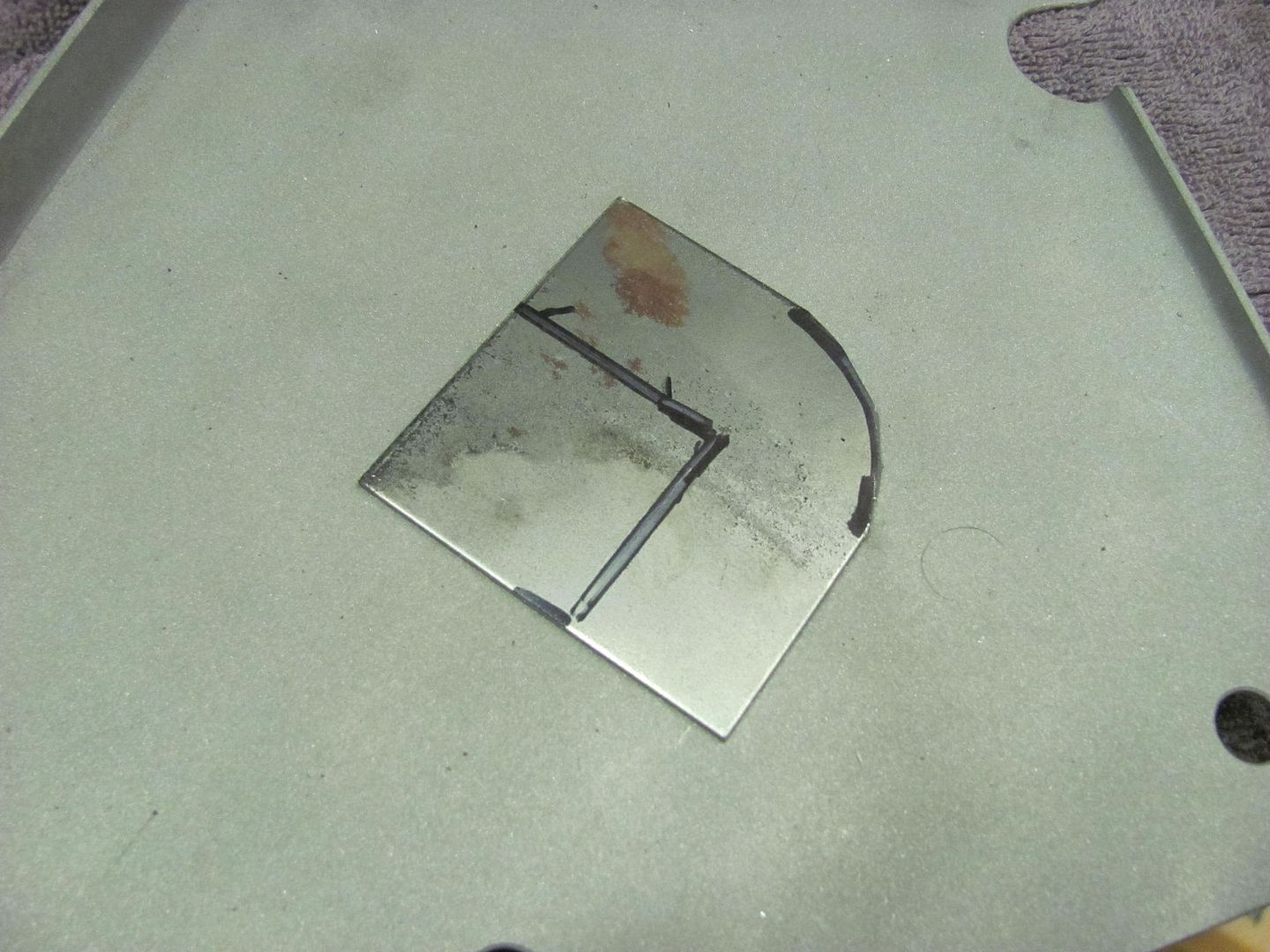

Today we worked on filling some holes in the battery trays. Hard to drill out a slot, so we clamped on a plate with a pilot hole to use with the Blue Point sheet metal hole cutter:

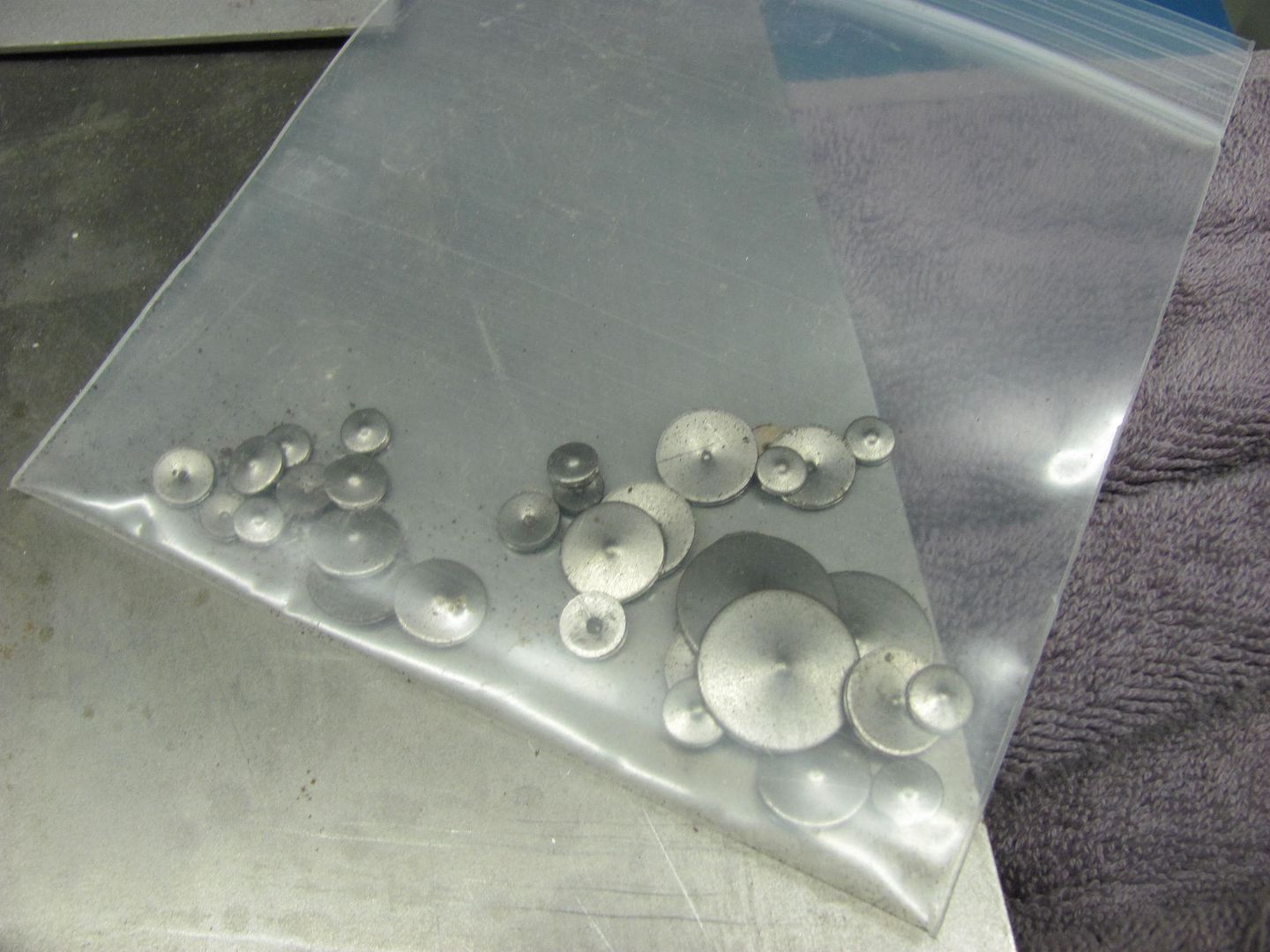

Plugs.....

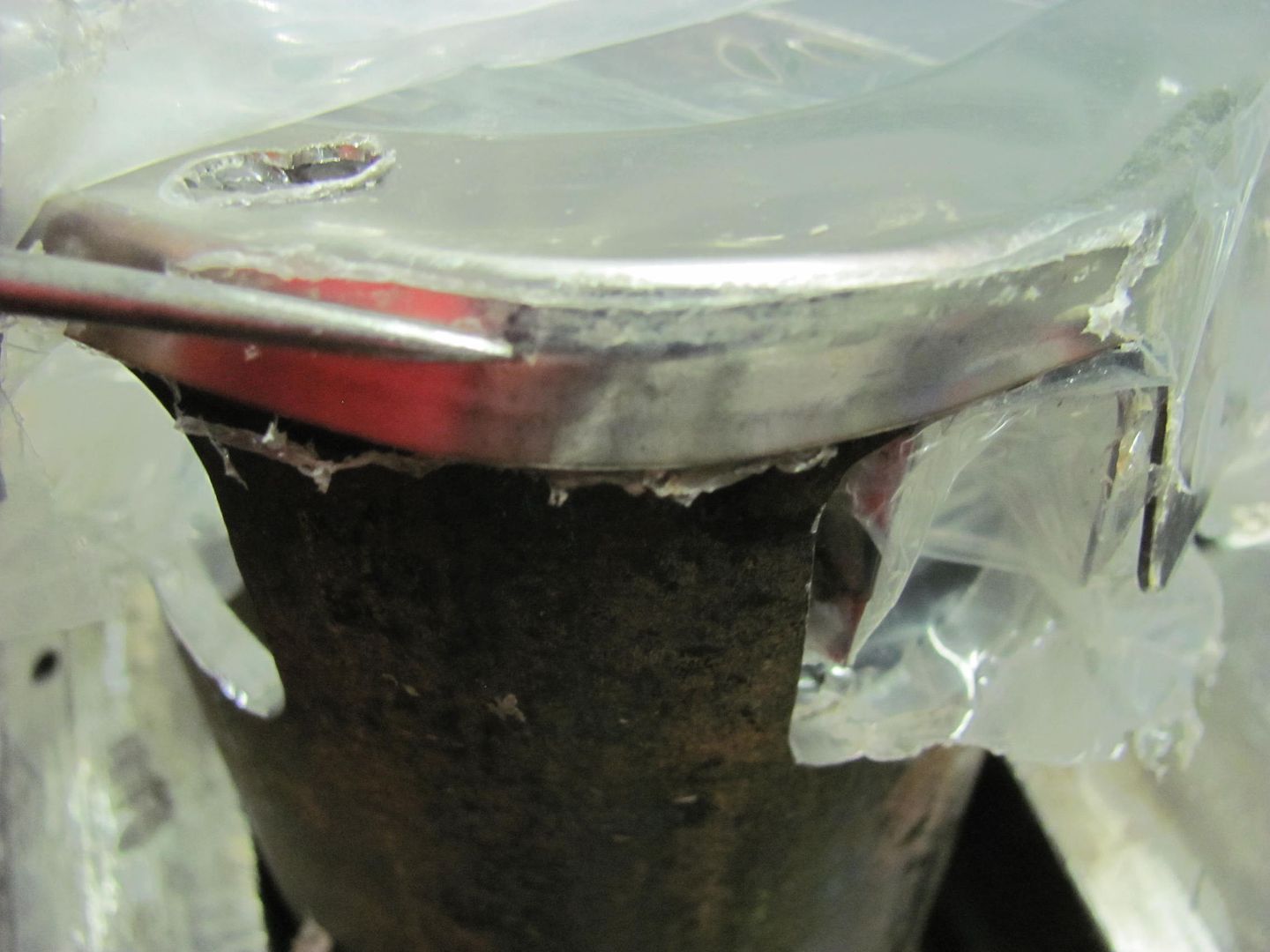

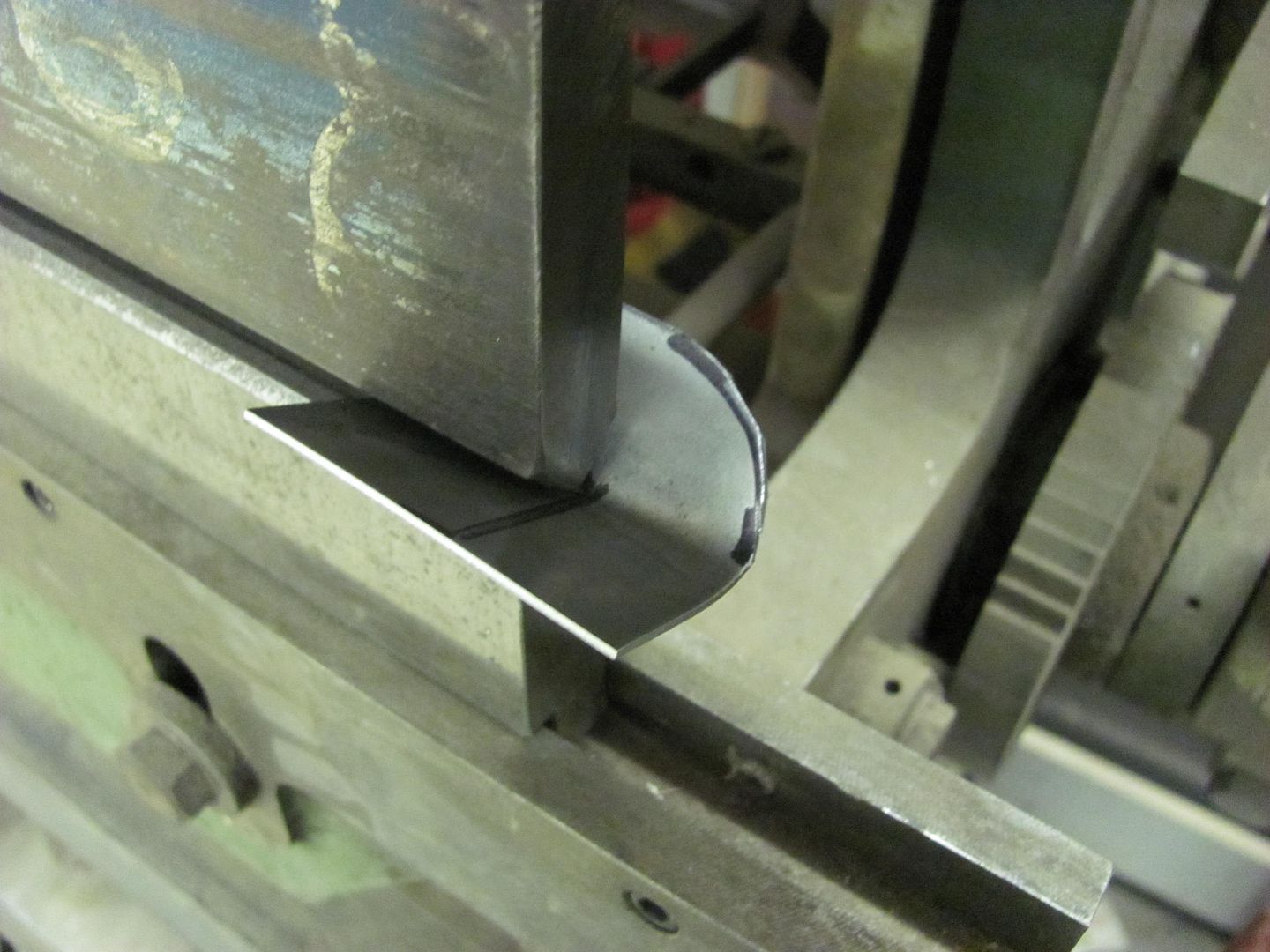

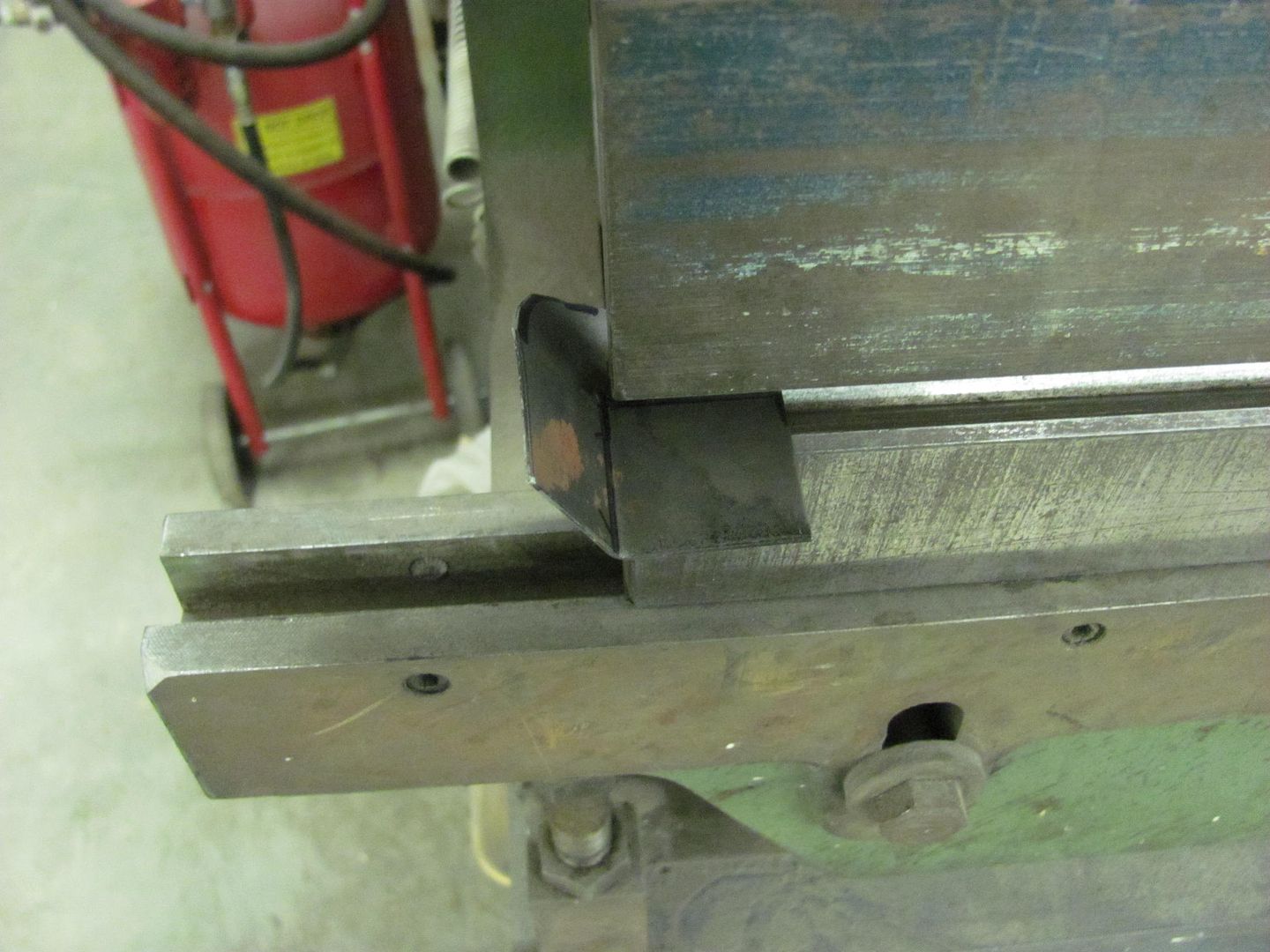

We tried this same repair in the corners, but the pitting was too far along and did a good job of blowing holes. So, time to back up an punt, let's make some new corners..

Shrinking the tuck....

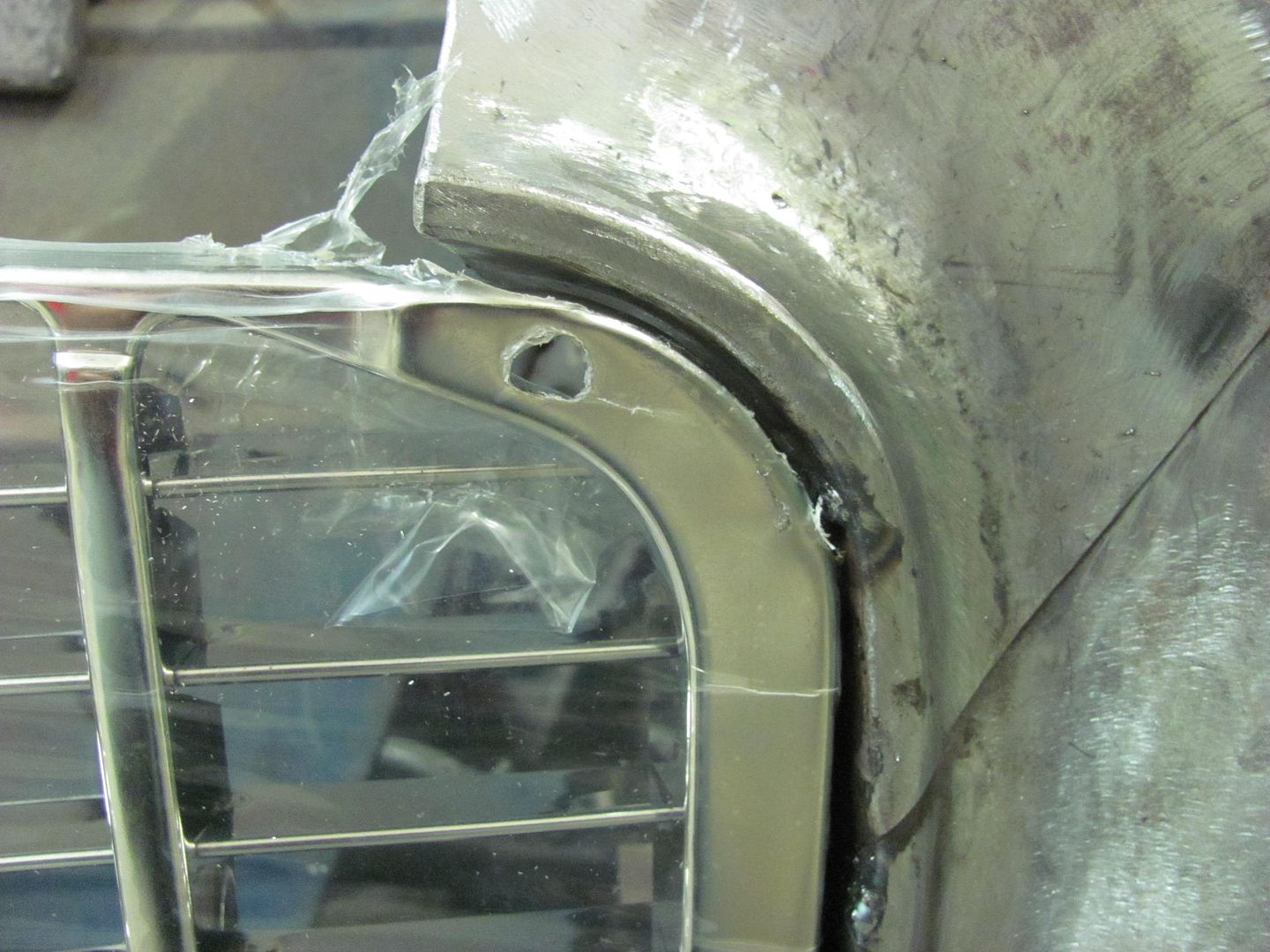

New corners welded in....

Some of the lines from forming were left to duplicate those from the factory...

Gusset bracket added to core support....

Holes located on inner fender....

Stiffener brace and angle bracket bolted in....

Tray bolted to the gusset, and plug welded to the angle bracket....

Battery hold down brackets added....

Got a couple plug welds to grind, media blasting, and these parts are ready for powder coating!

Reply With Quote

Reply With Quote