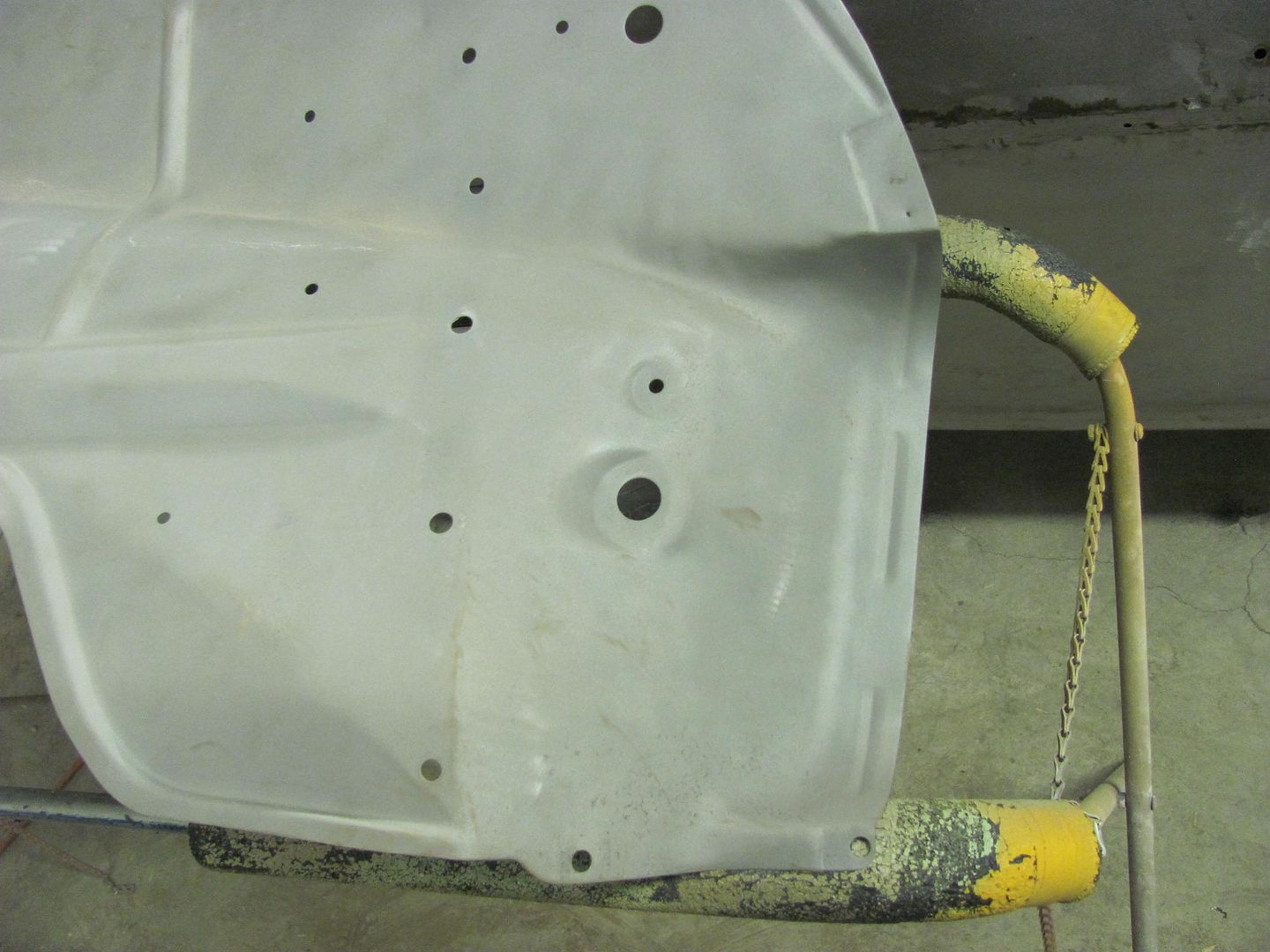

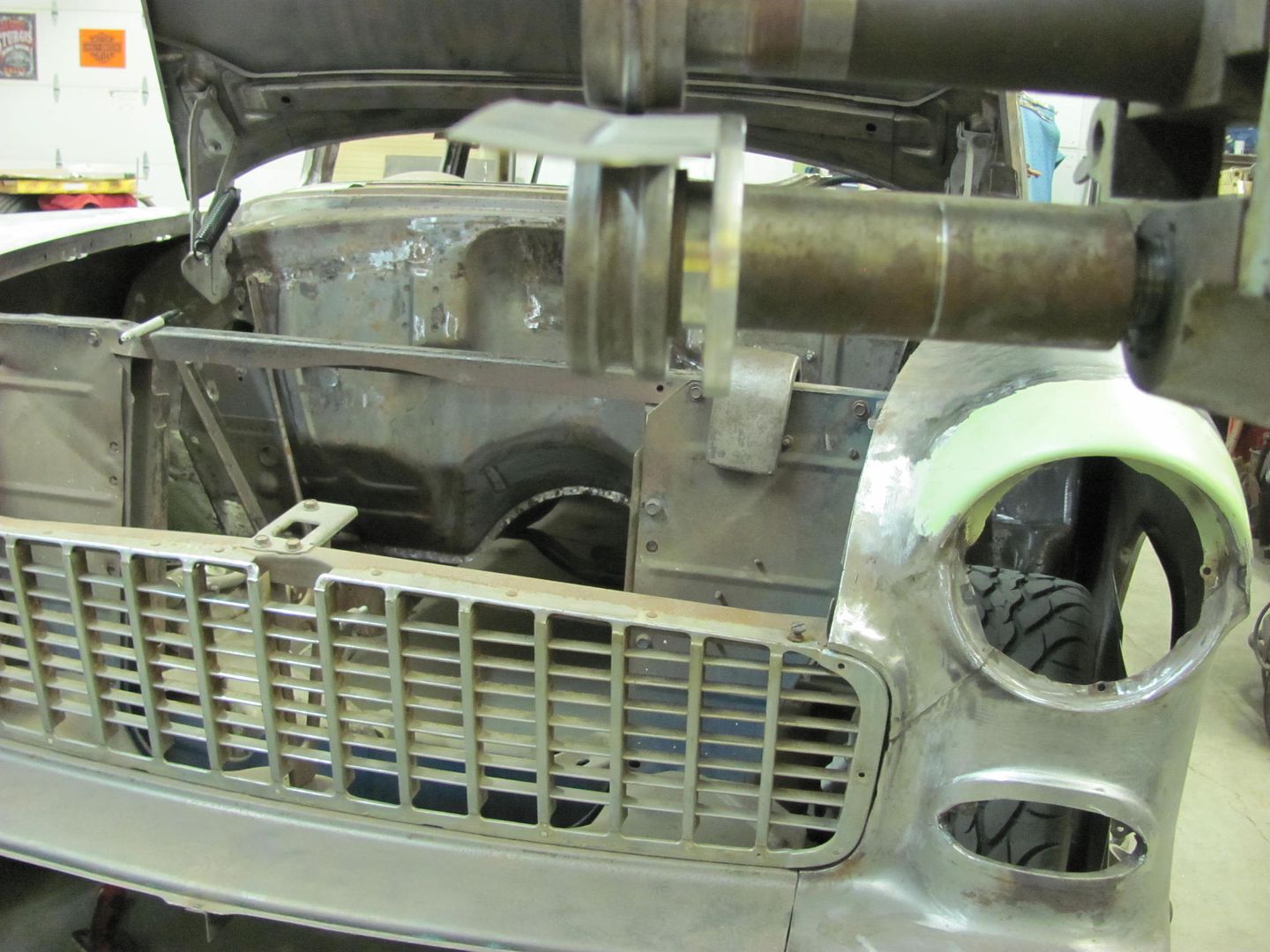

Last night we turned our attention to inner fenders. We've got some items

slated to go out for powder coating, and these will get added to the pile.

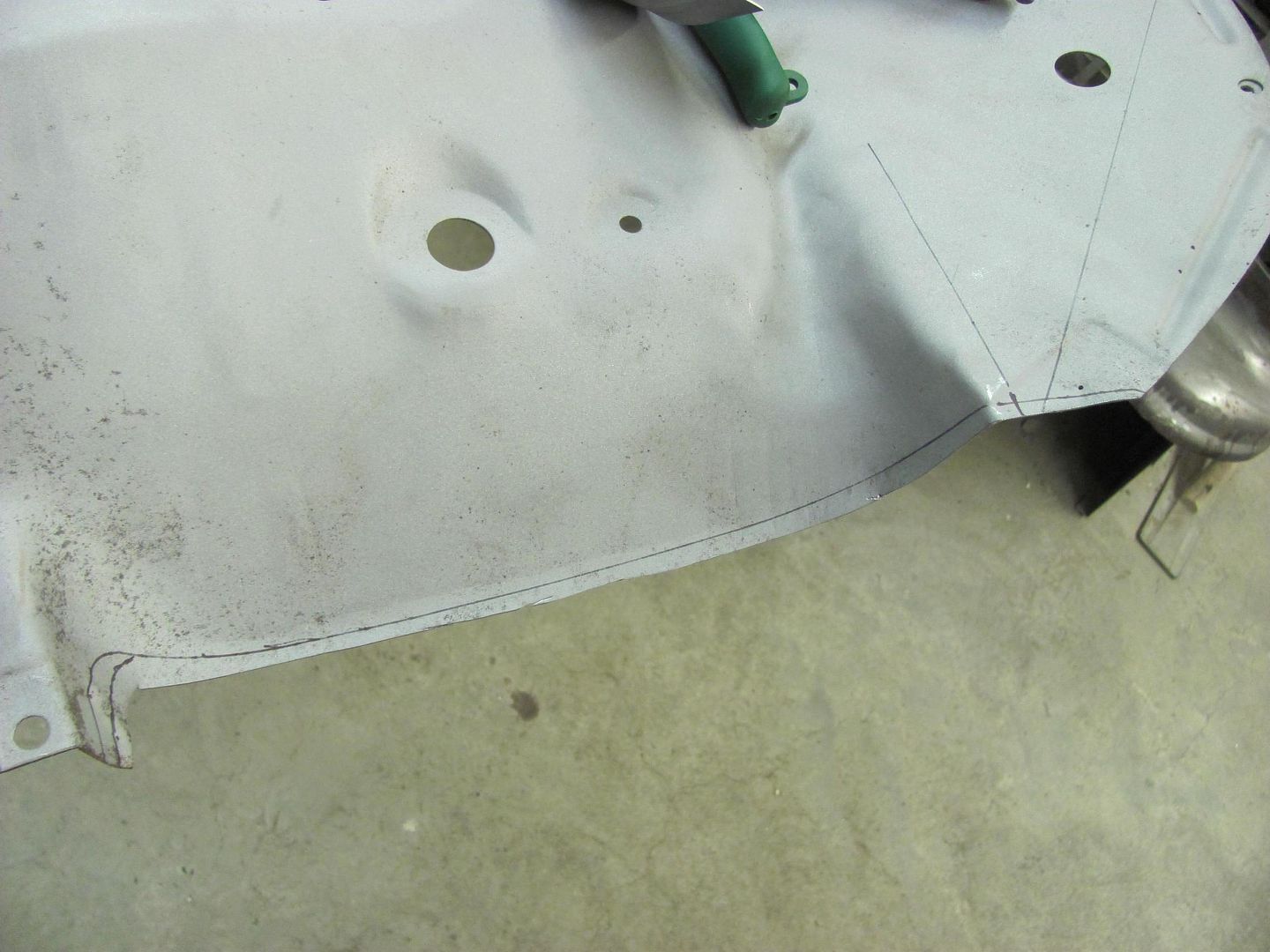

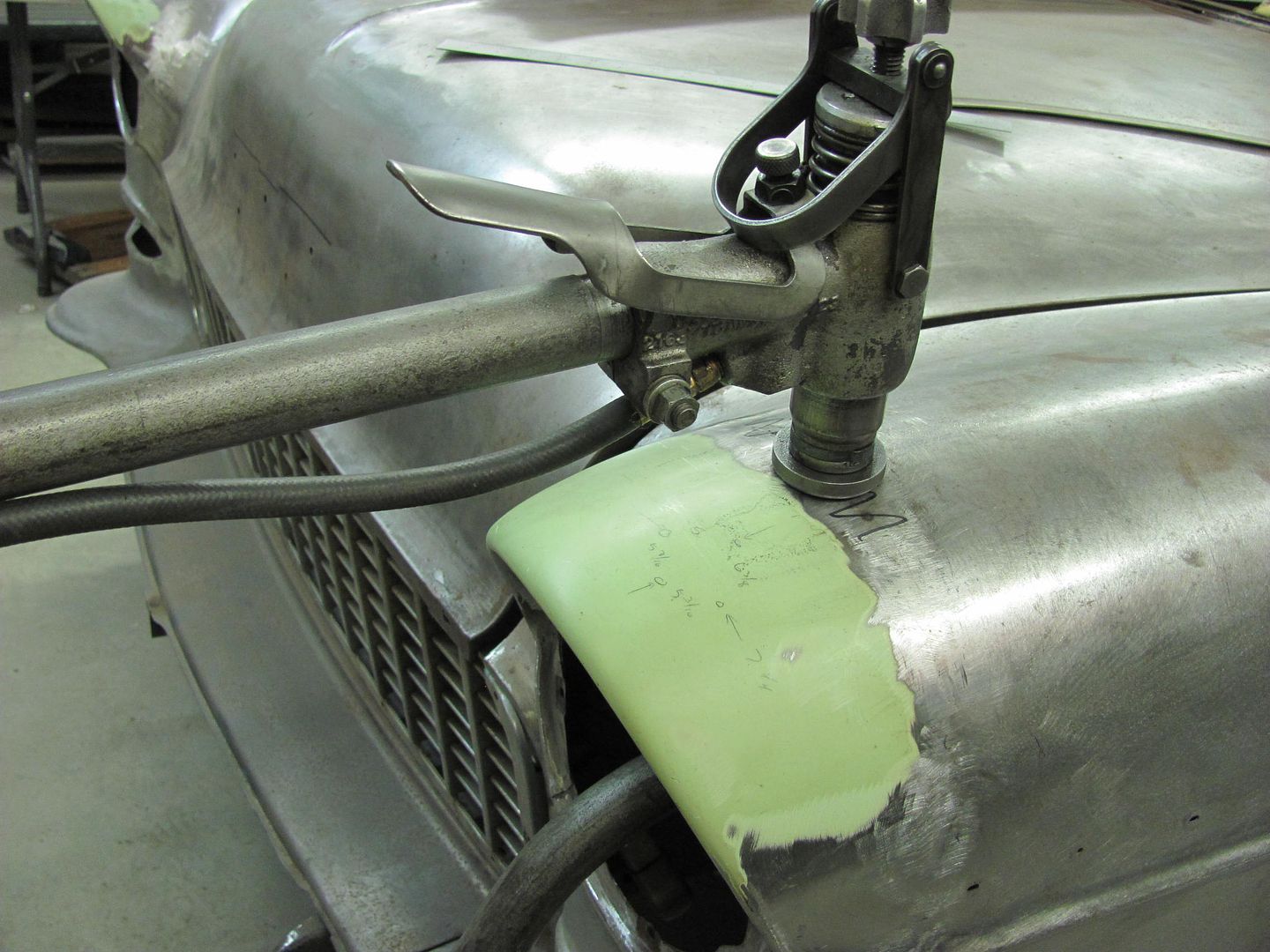

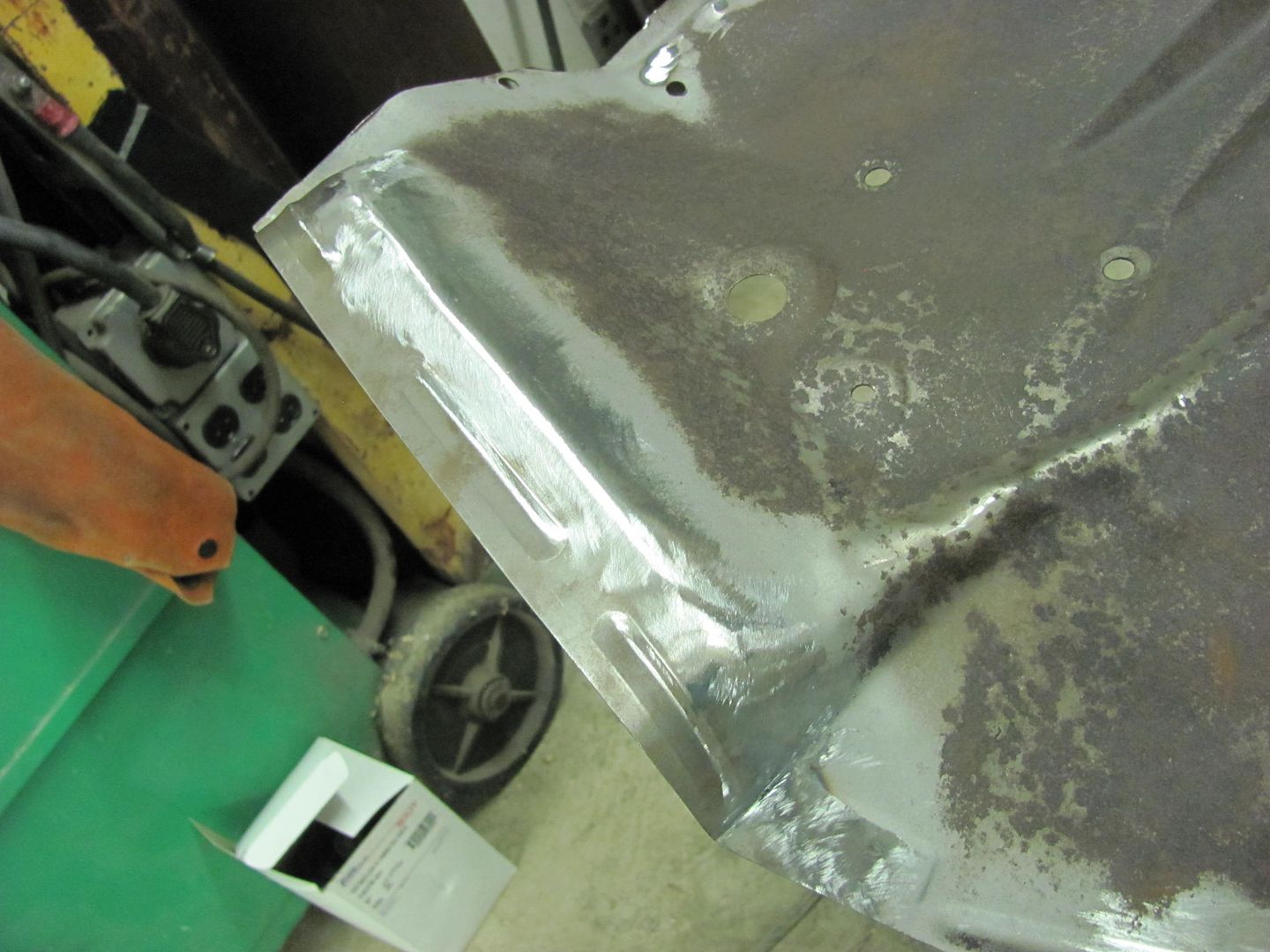

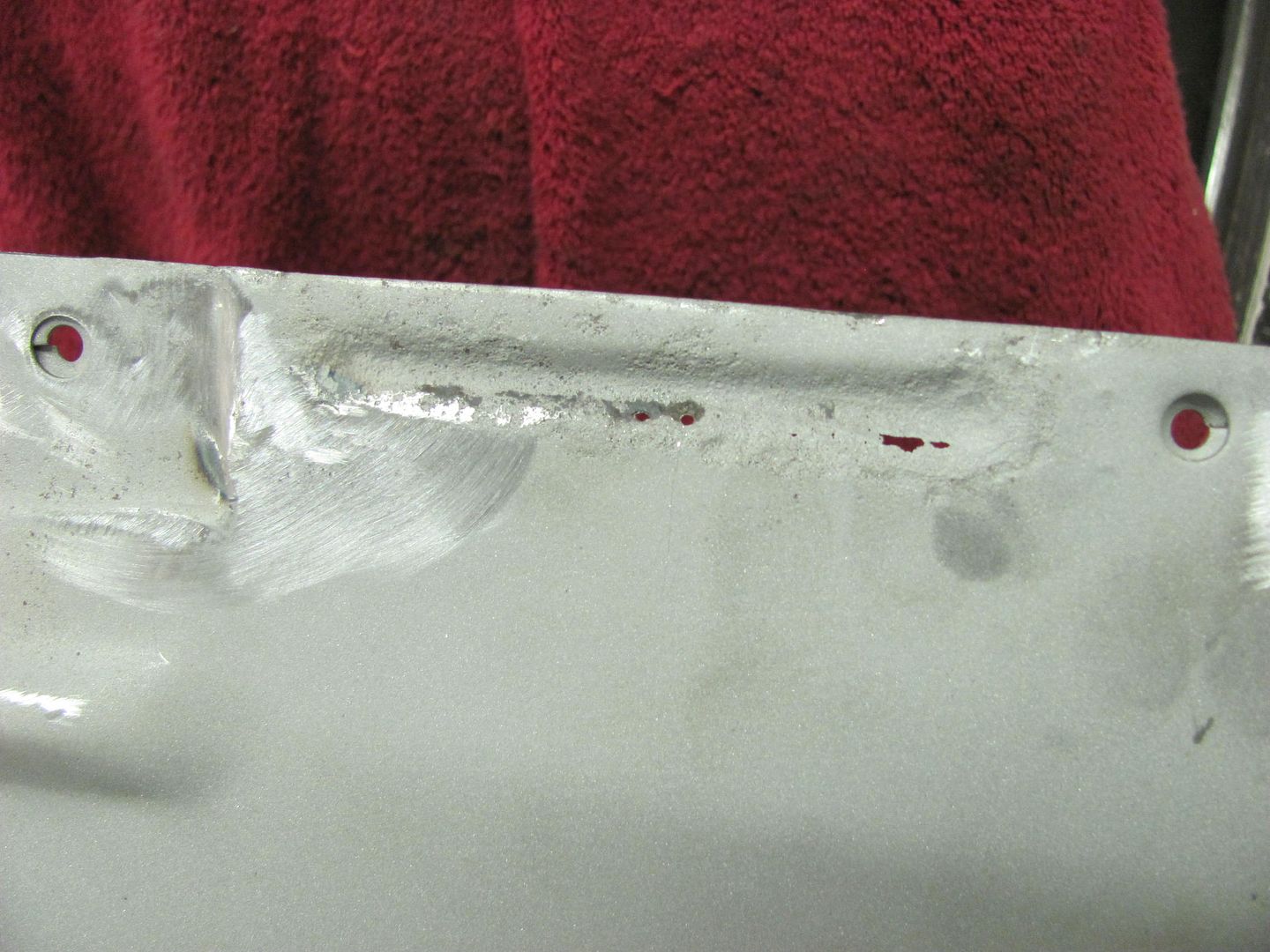

The front edge that bolts outside the grille is showing remnants of water

retention...

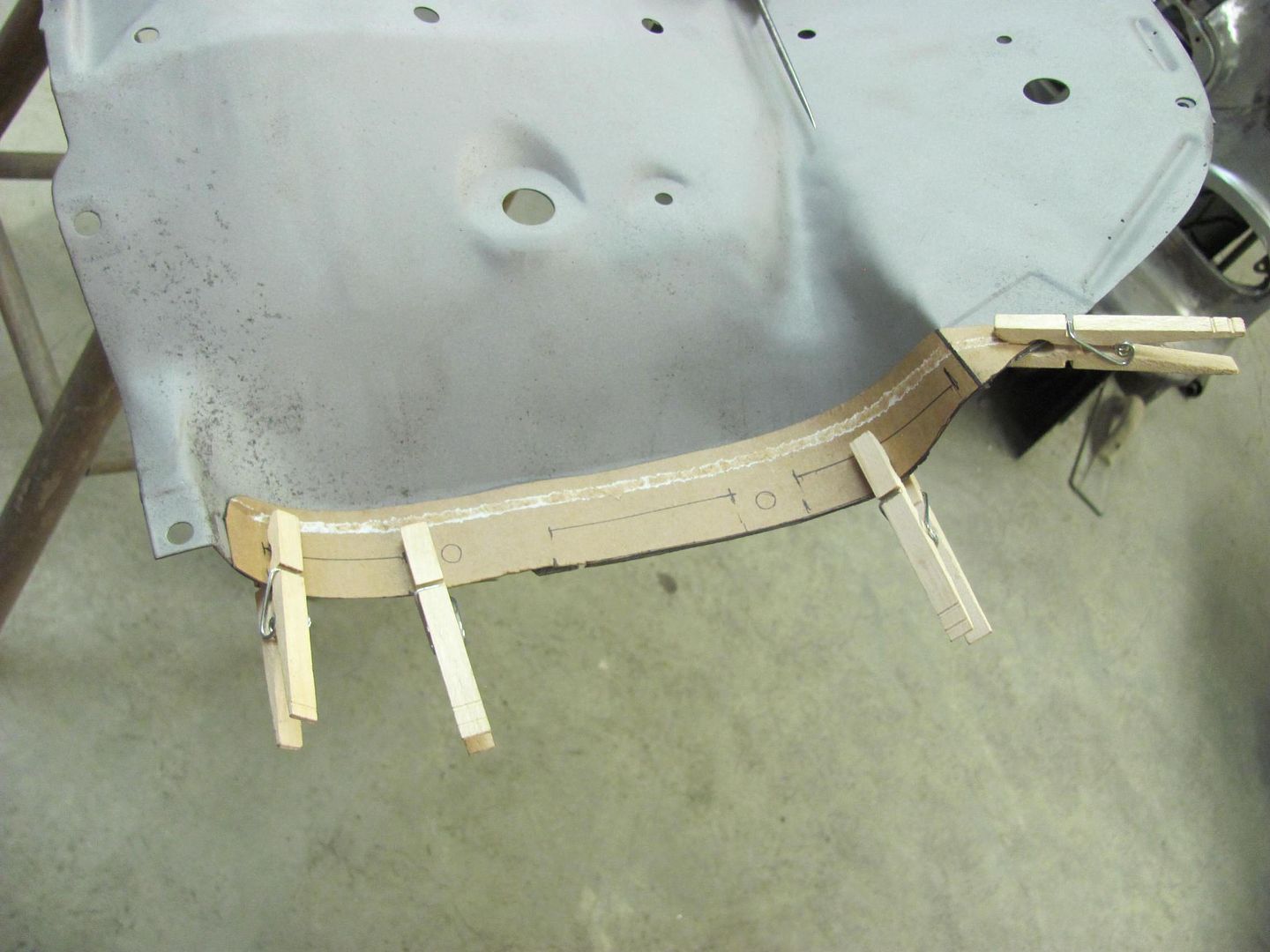

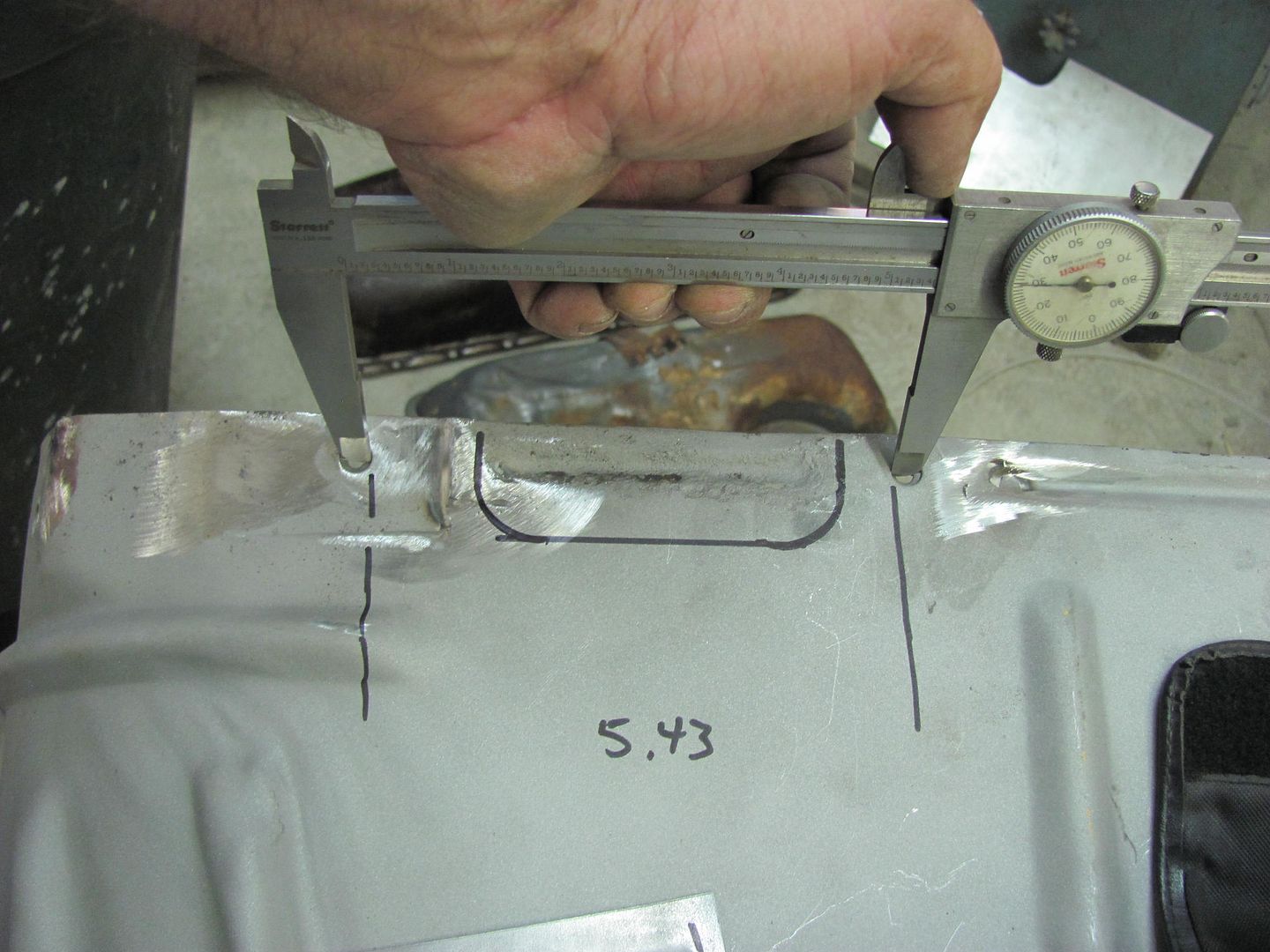

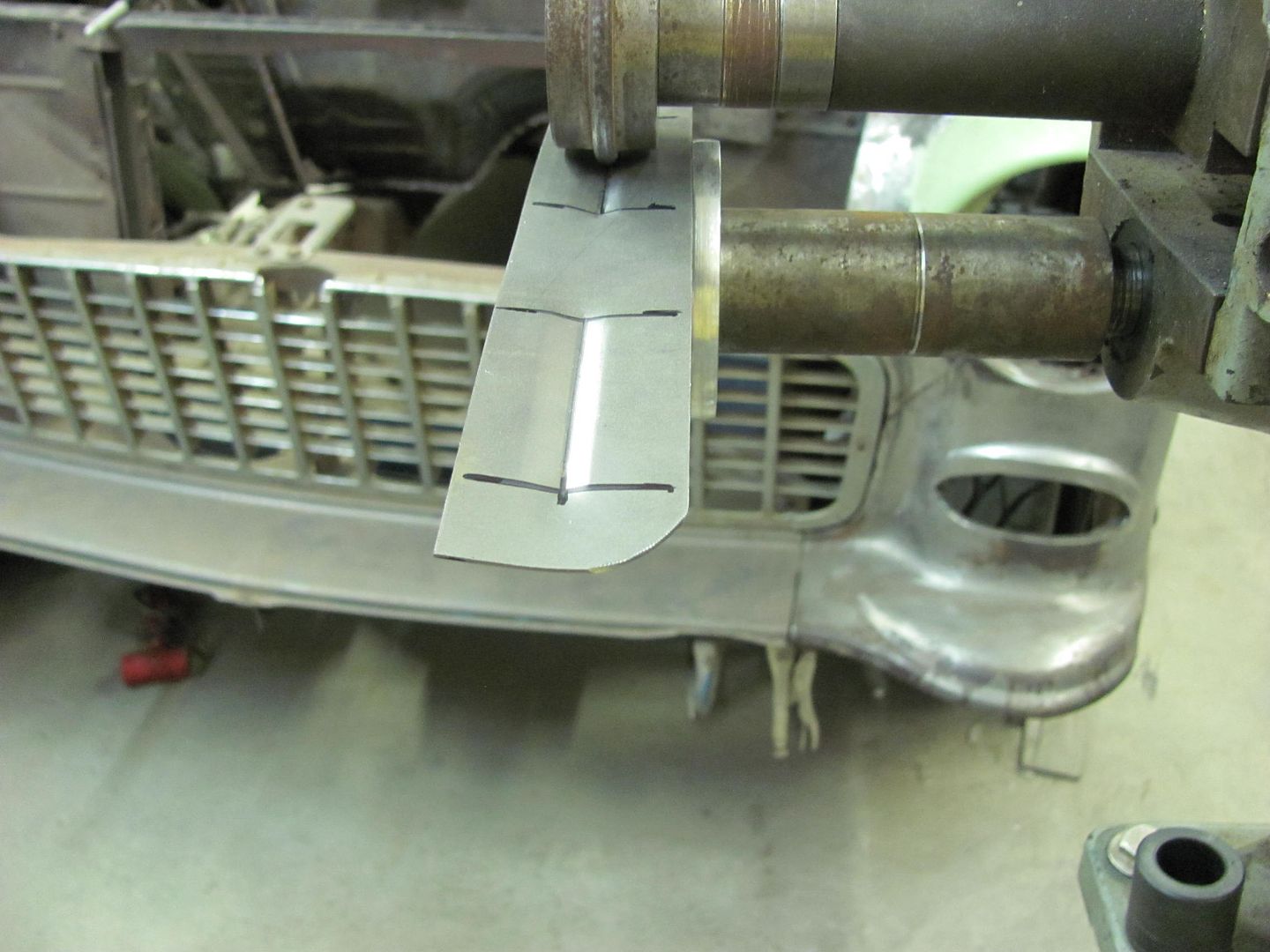

Mountain Dew template

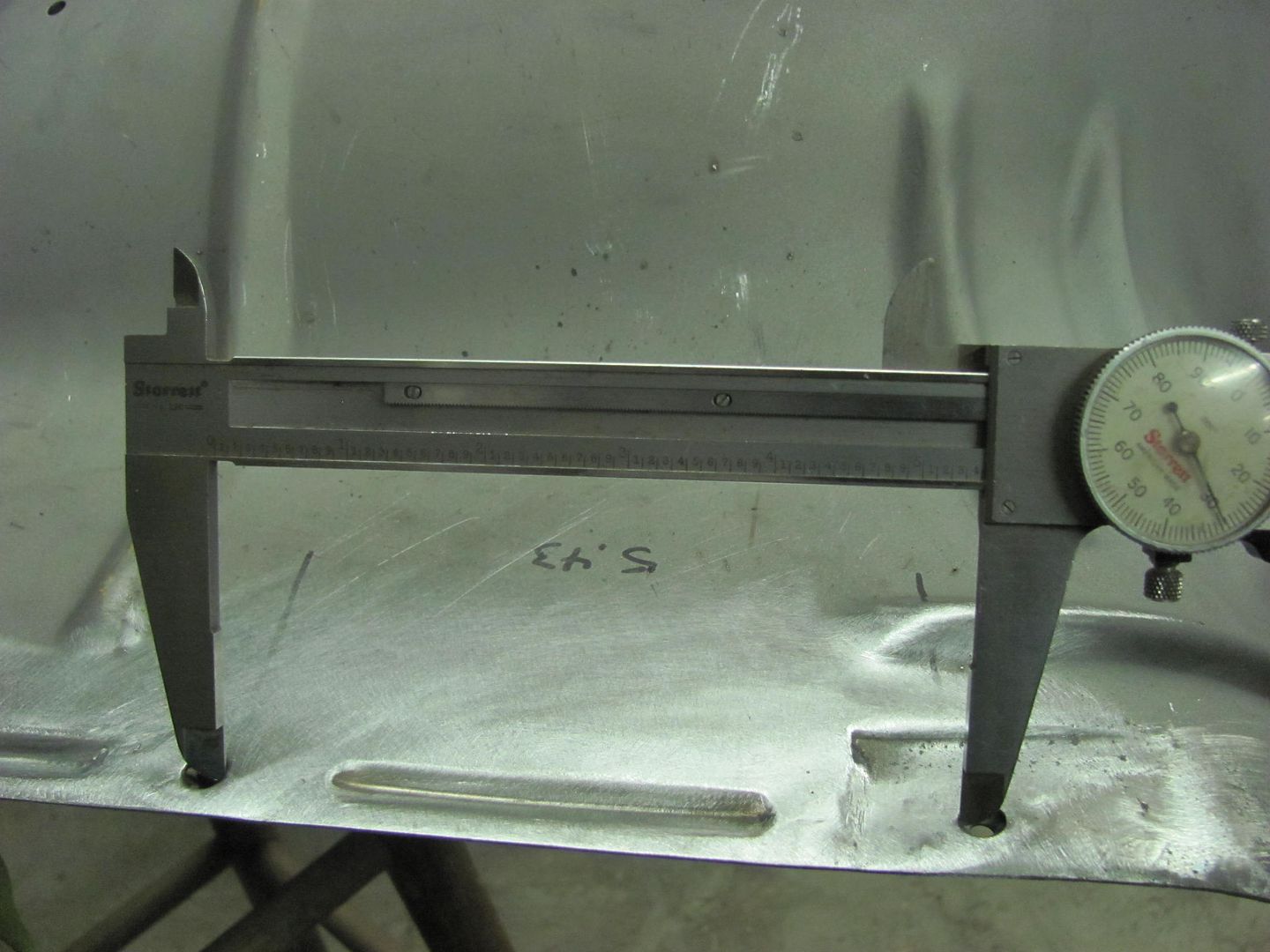

Bead's male die is offset to one side to match the originals.....

Bead roller was set up with a backstop die...

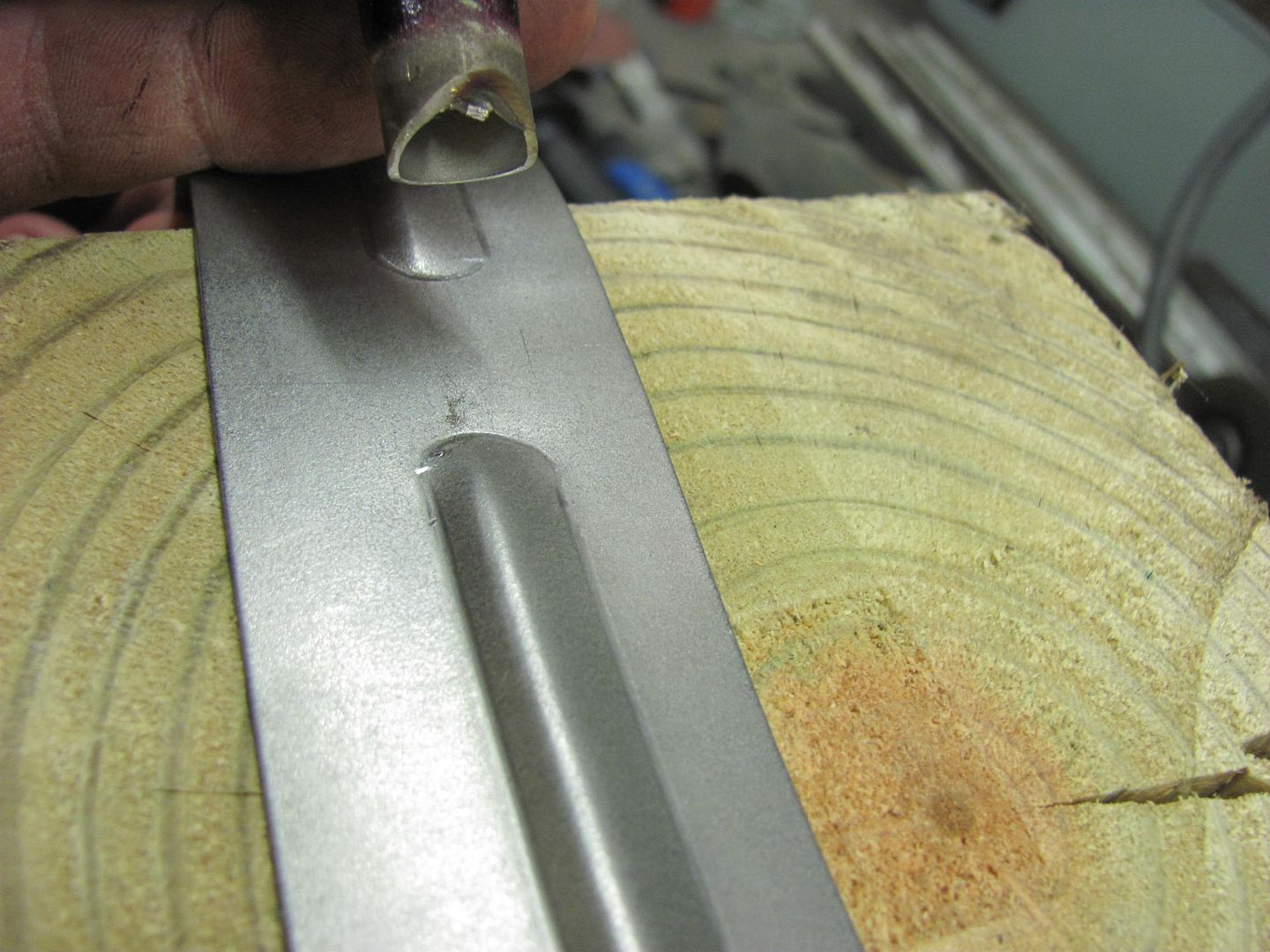

Skateboard wheel and "rolling" wheel used to add radiused ends....

Grabbed a suitable scrap from the pile and used the sander to make a bead

ender tool thingie, used on the treated 6x6 anvil...

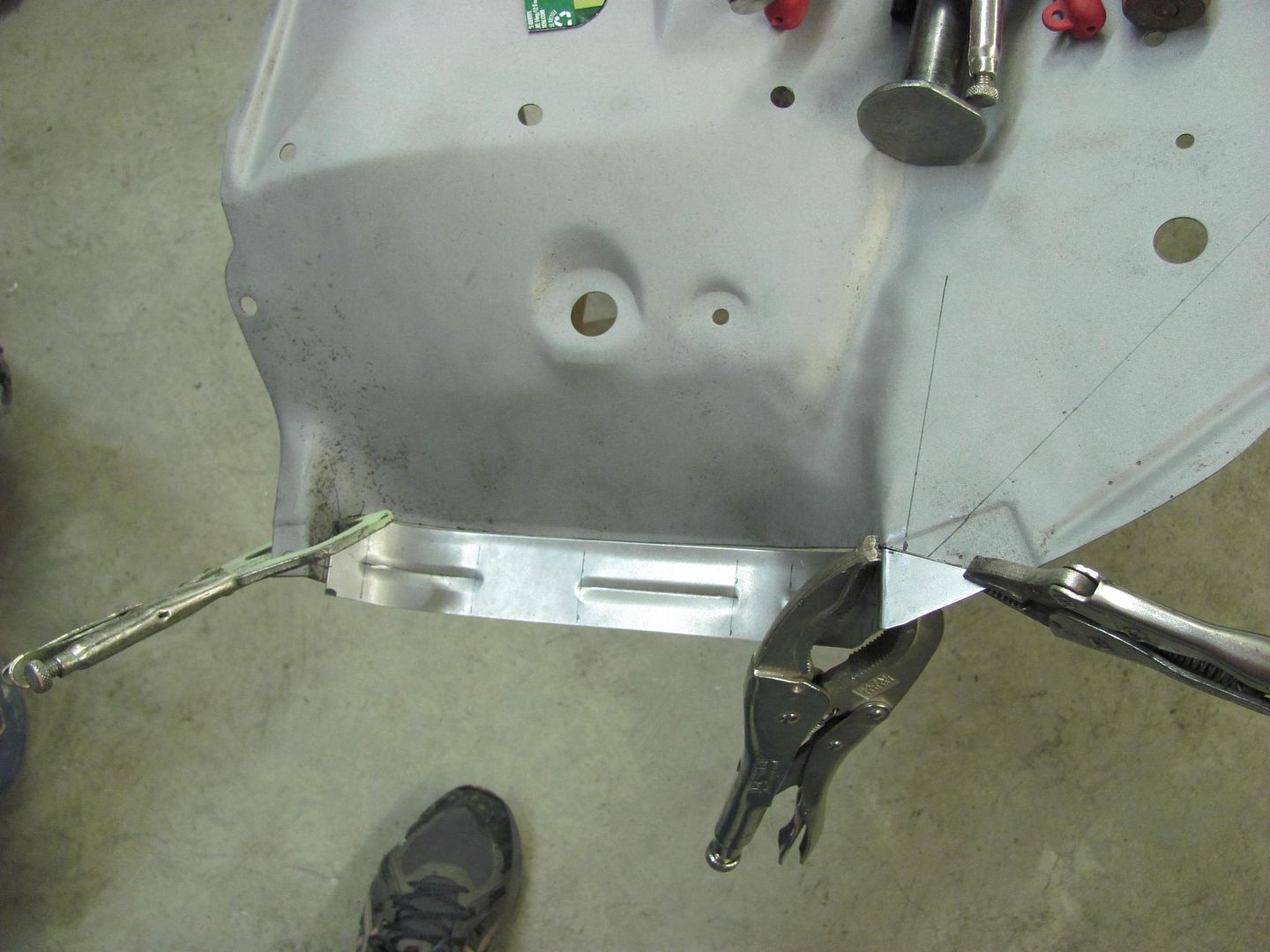

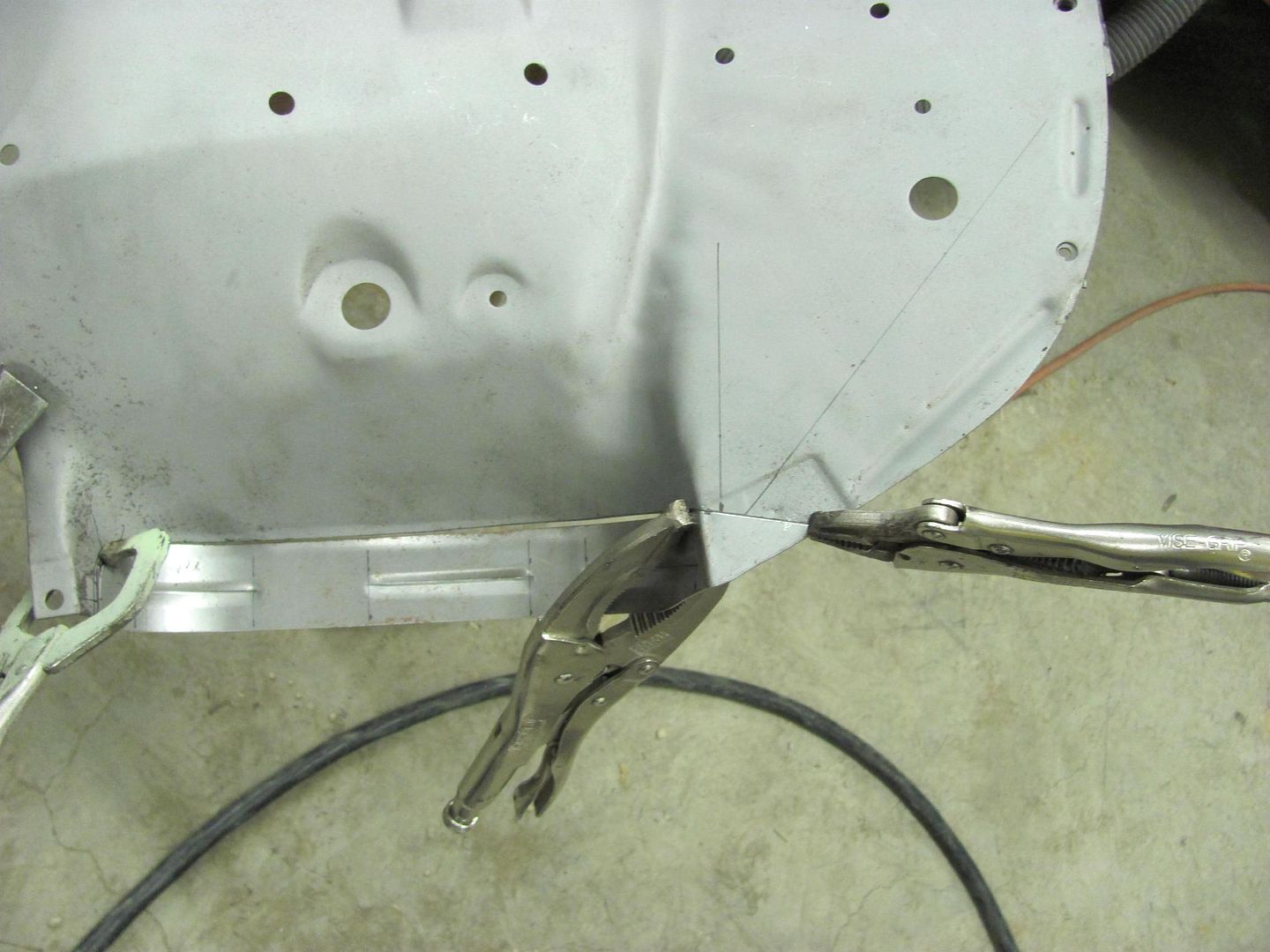

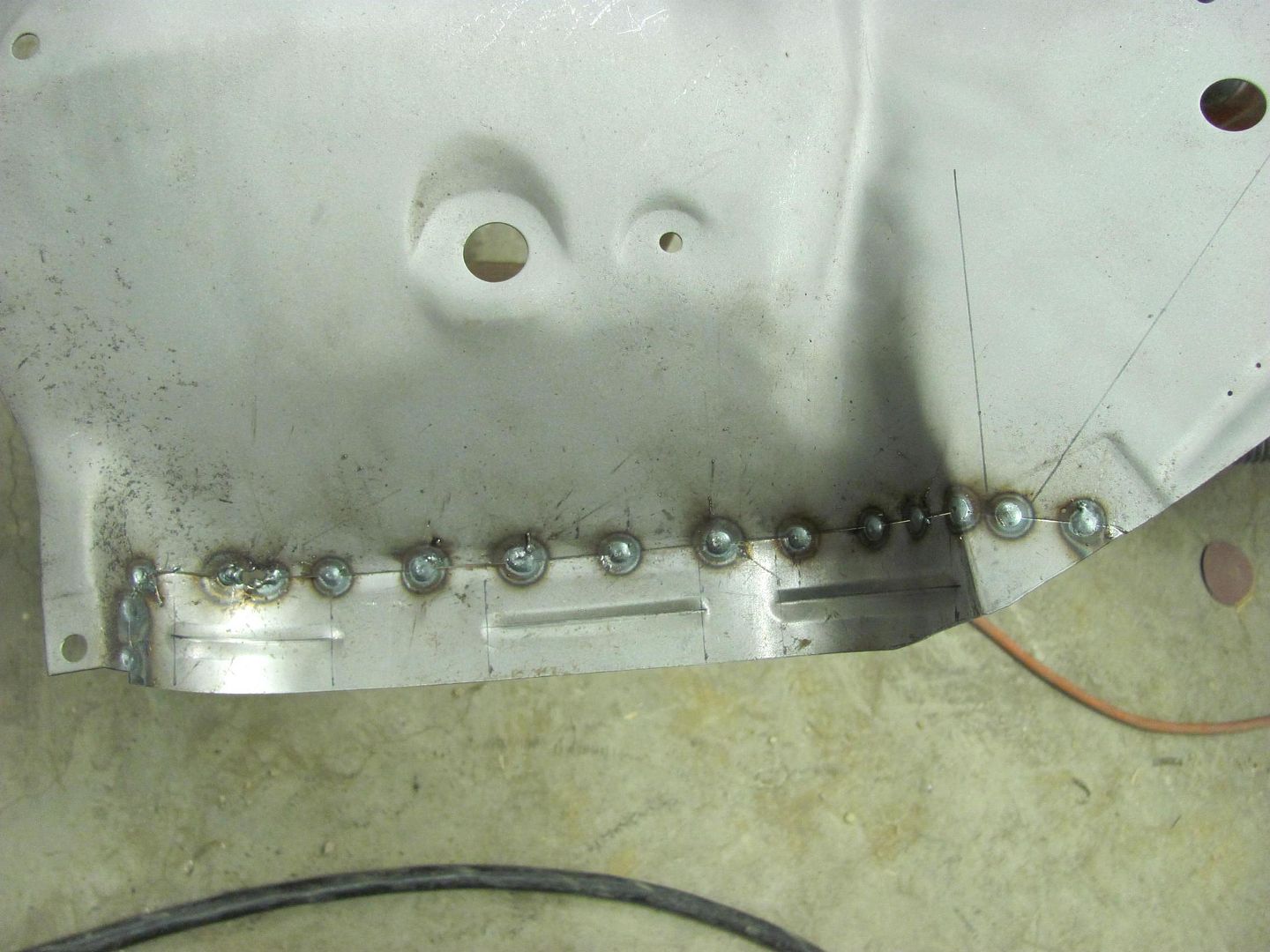

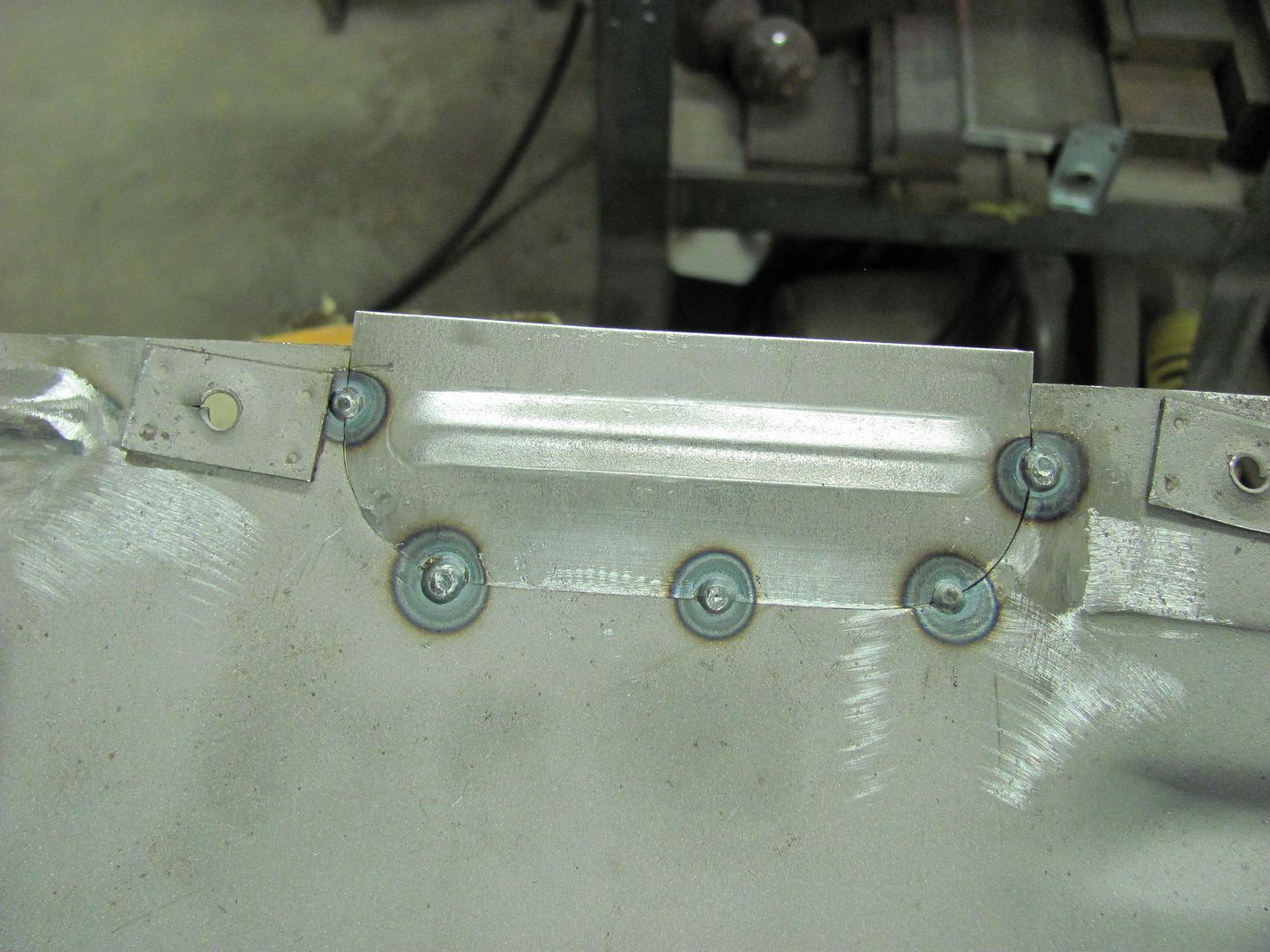

Clamped and tacked....

More tonight......

Reply With Quote

Reply With Quote