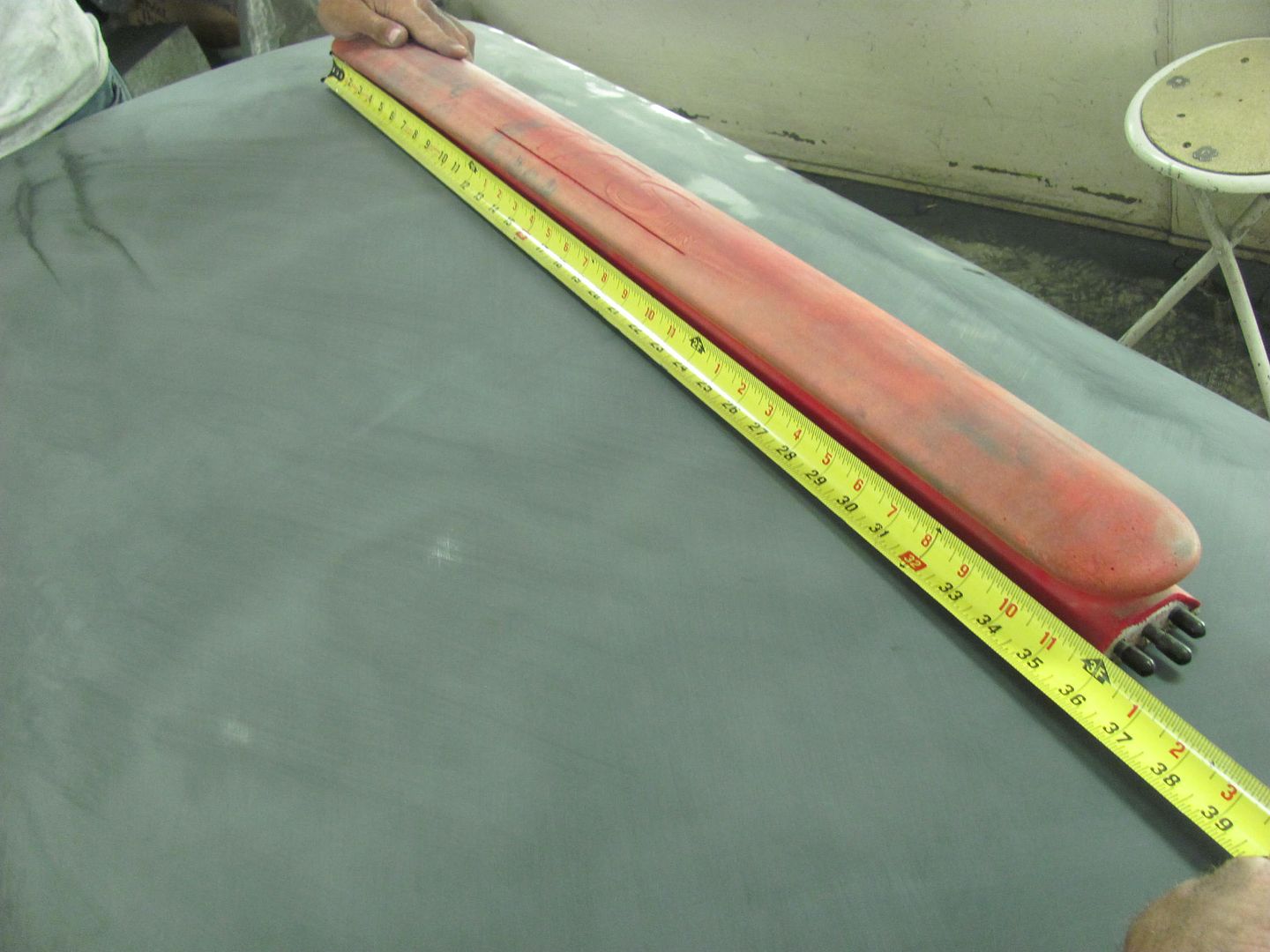

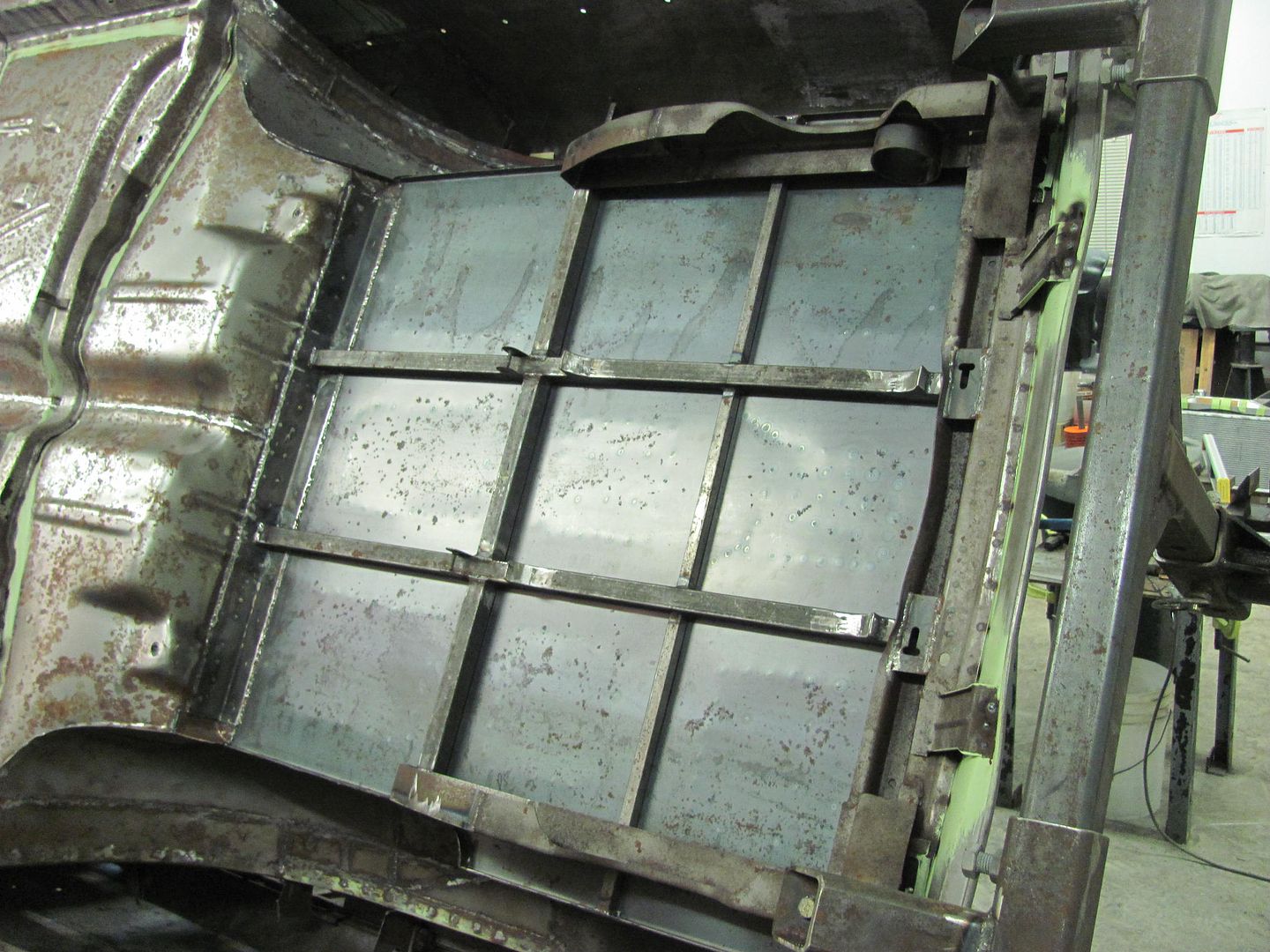

Another job in the shop, here's one of the downfalls of the insulation blankets the factory used above exhaust systems...

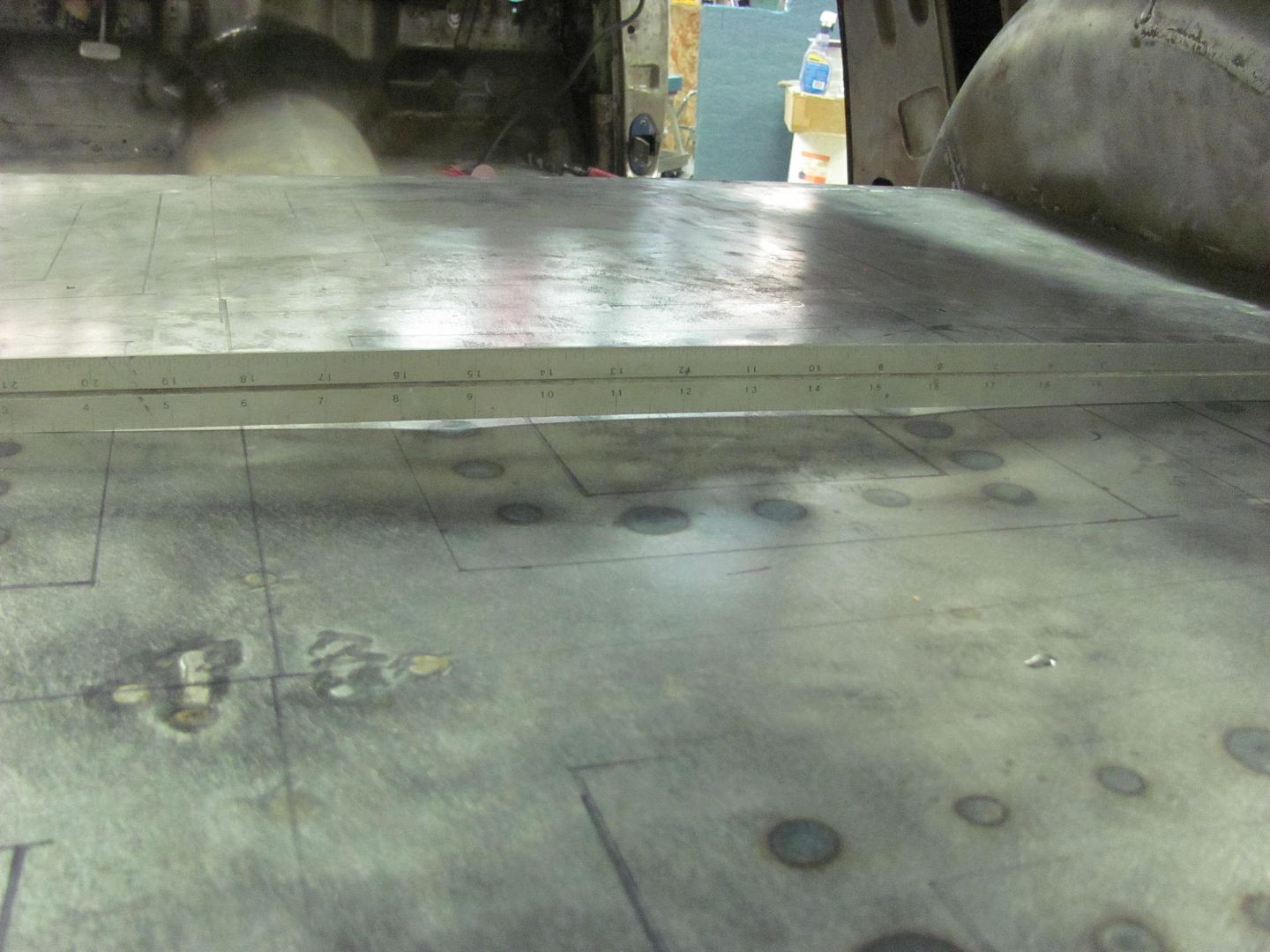

Nice moisture traps and rust generators. All the used beds found either had similar rust issues or the lower quarters rounded under where the salvage yards had removed them and set them down on the ground. So we went back to the local dealer and ordered the bed floor and new cross members. We have a couple cross members that still haven't arrived, but we can get started in prepping for epoxy primer on the parts we do have..

Scuffing up the floor using 400 grit. Here's the new apprentice for this job, my niece Katie. (her truck) She's not afraid of work and needed little instruction.

All scuffed, now to wait on the cross members to come in..

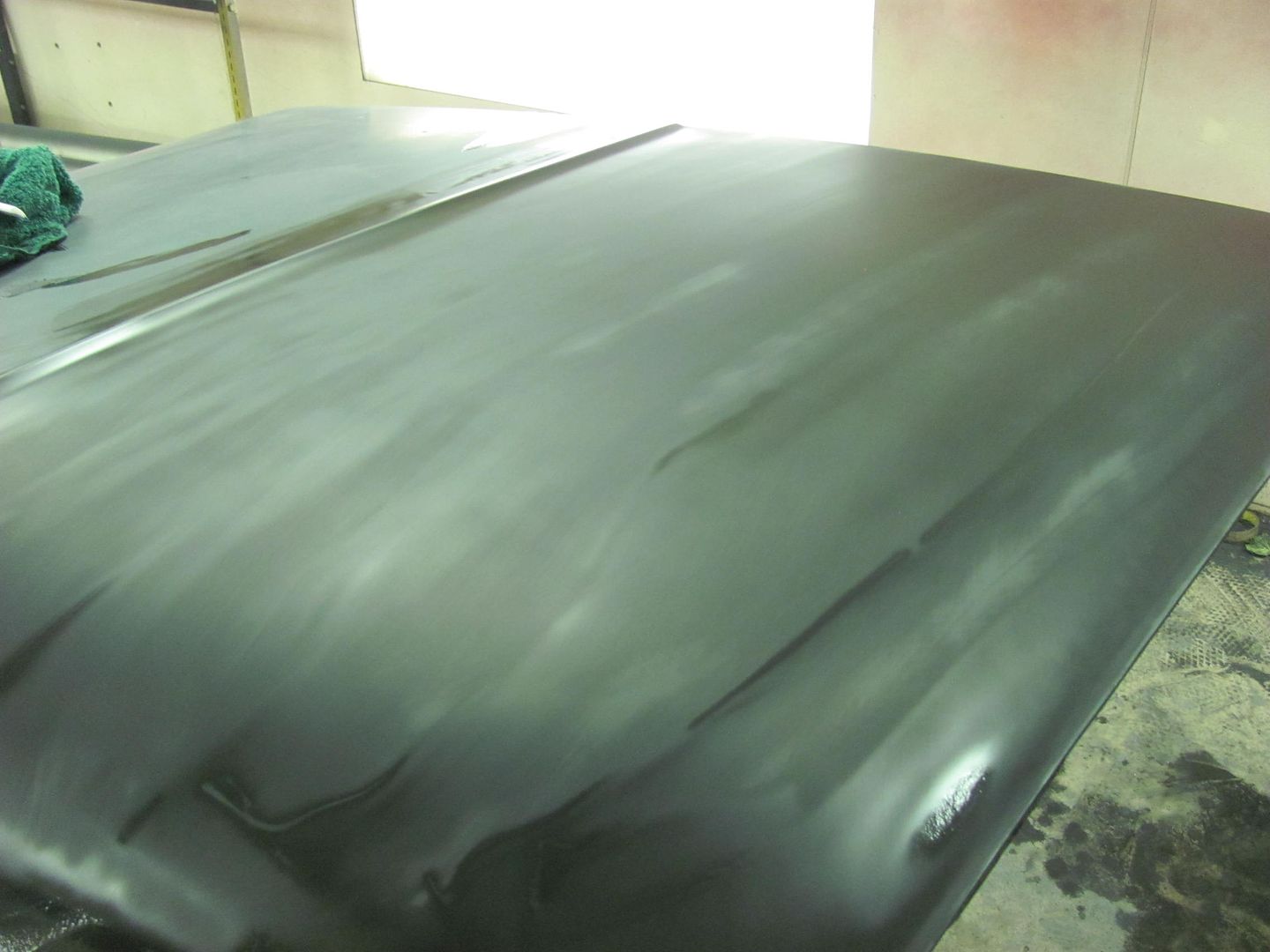

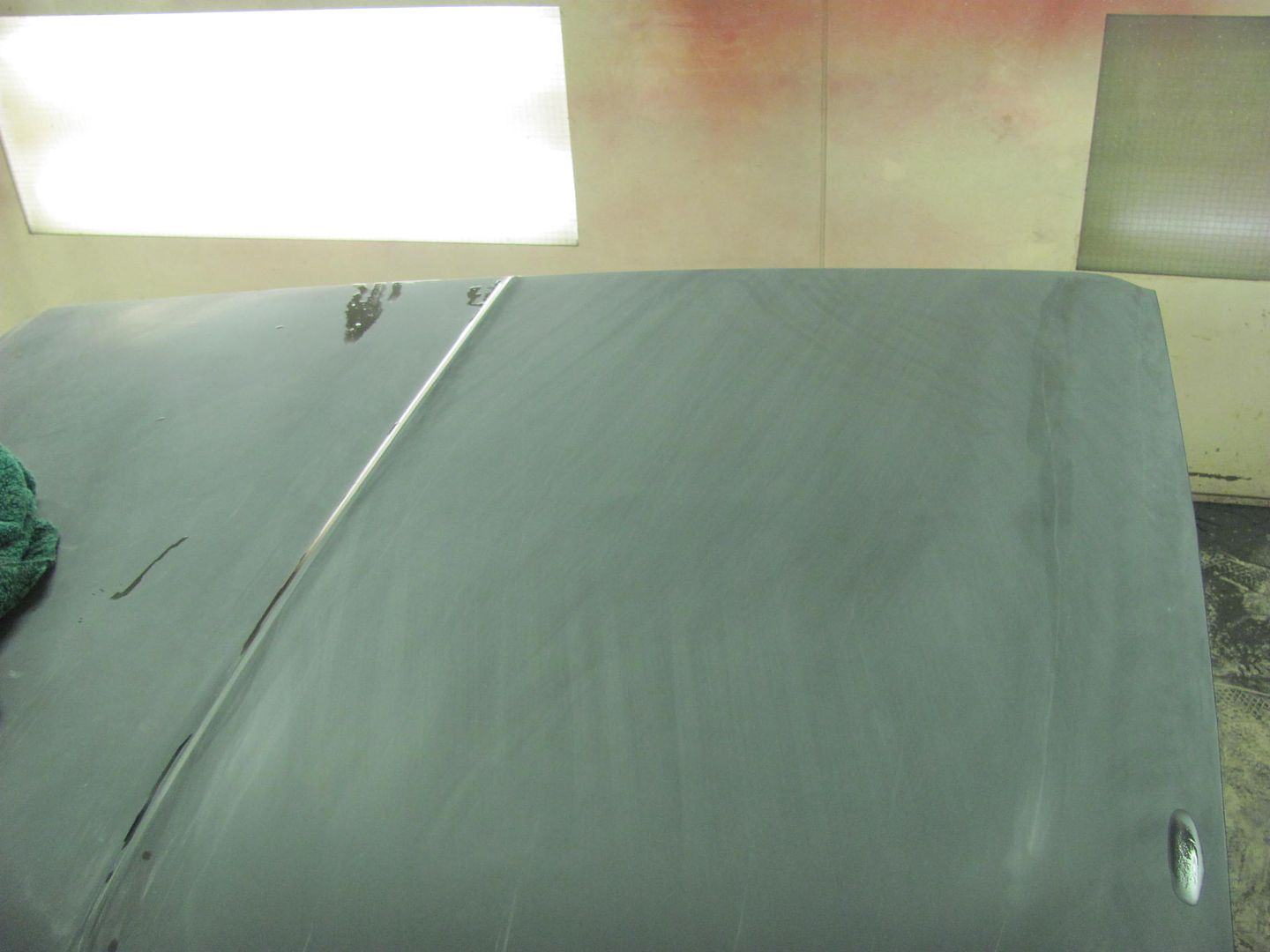

Meanwhile Kyle and I have continued blocking body parts for another dose of epoxy...

Reply With Quote

Reply With Quote