Project updates for todays class:

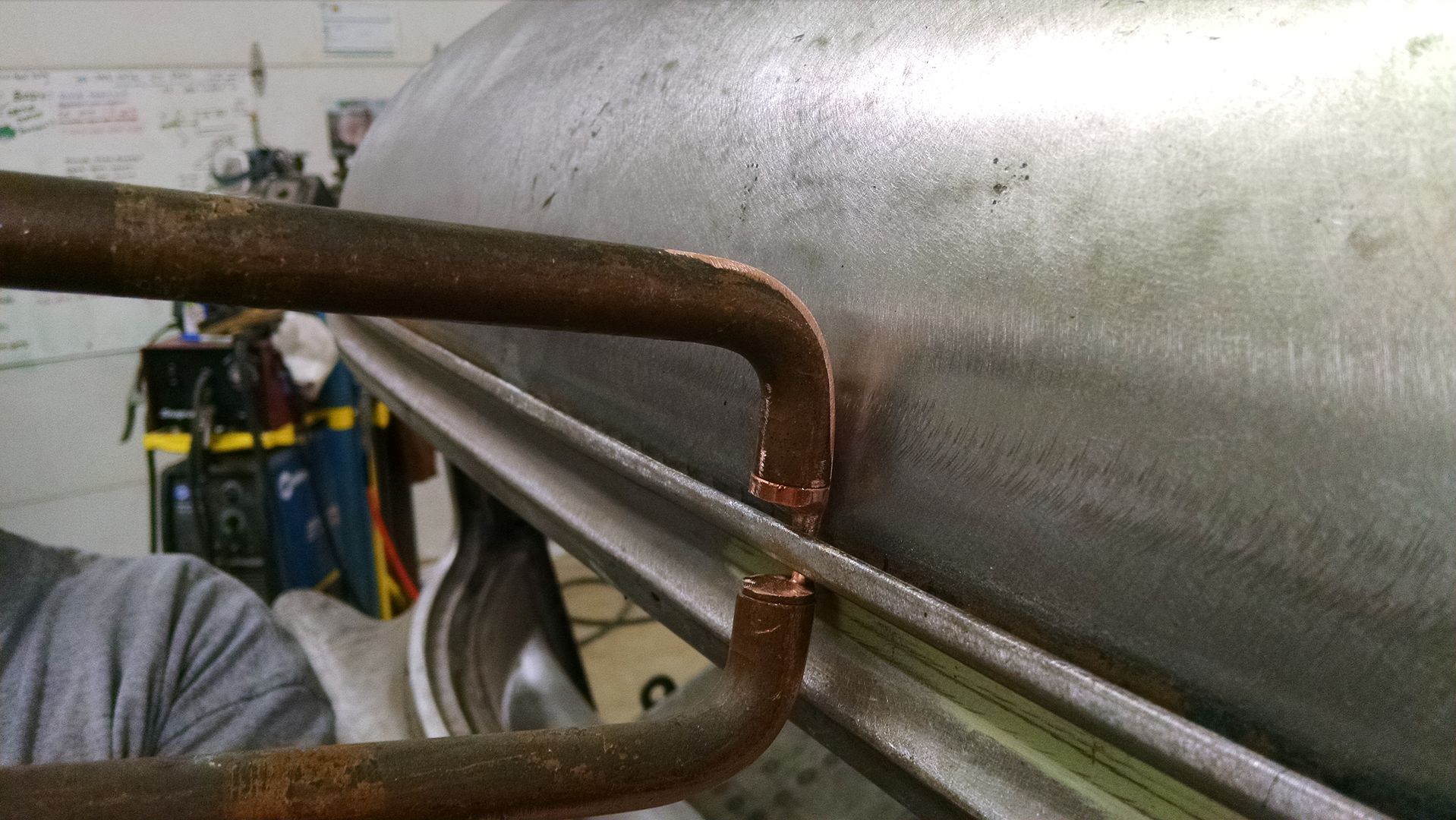

Wiring top edge of the copper trash can..

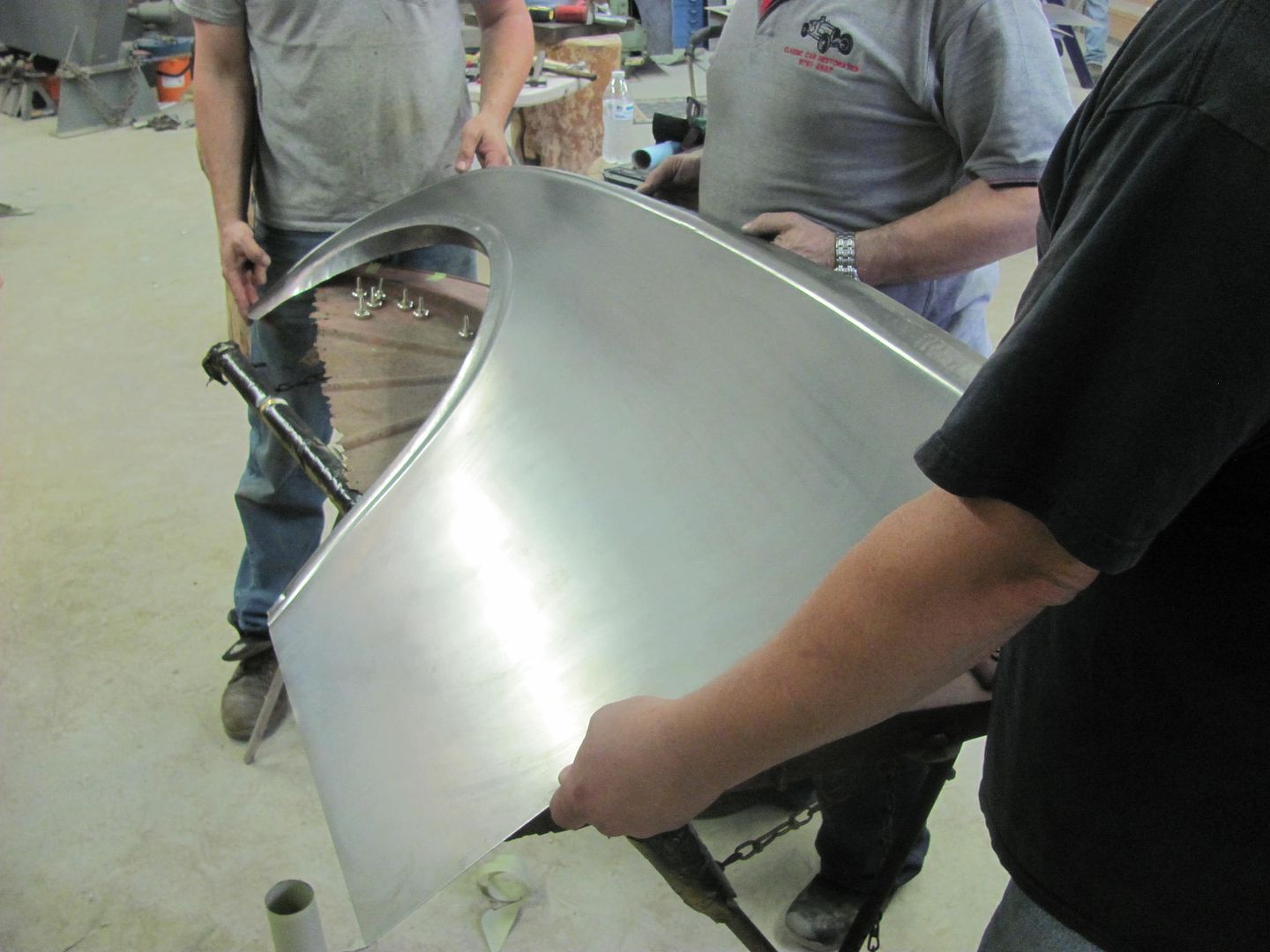

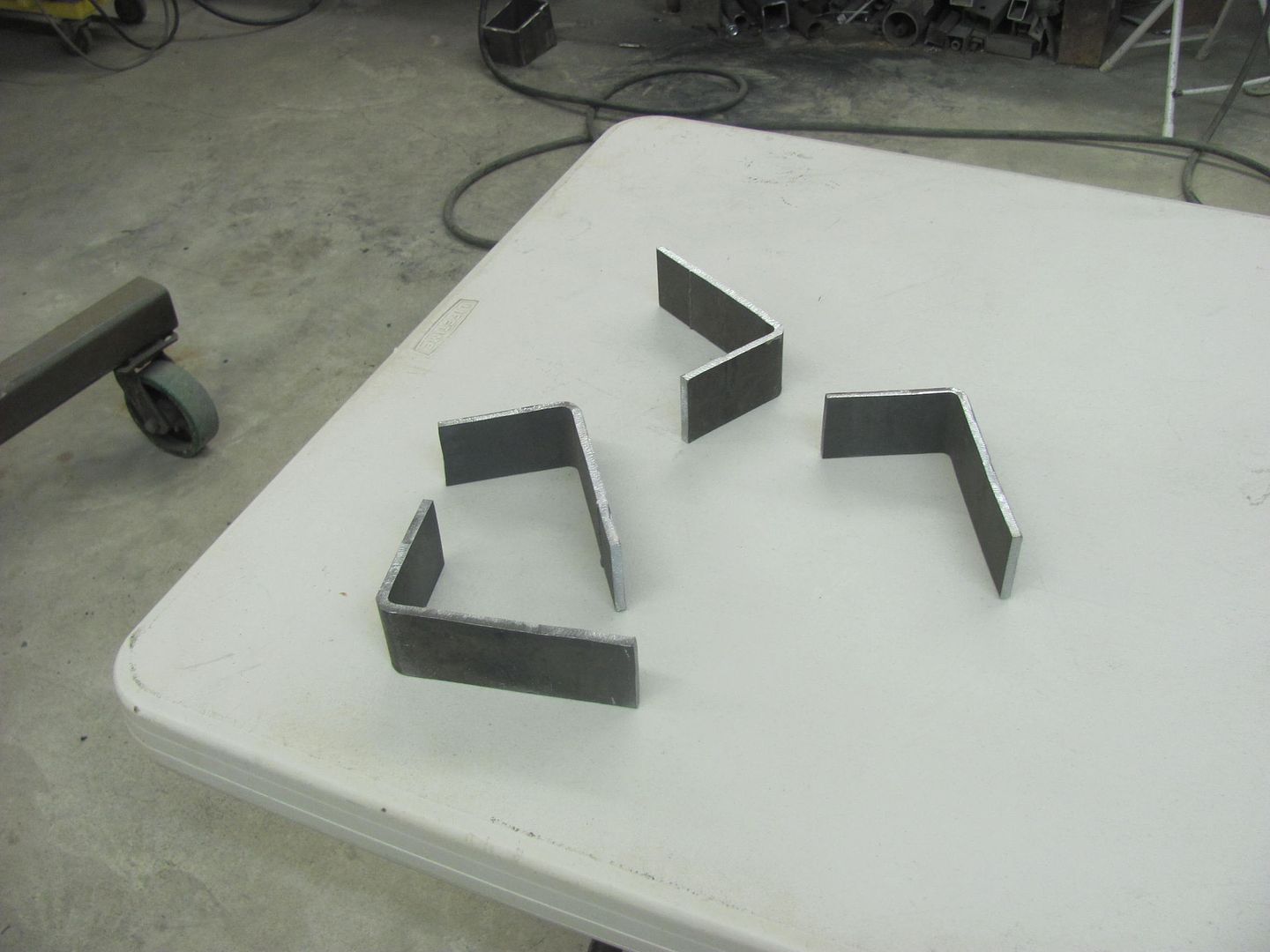

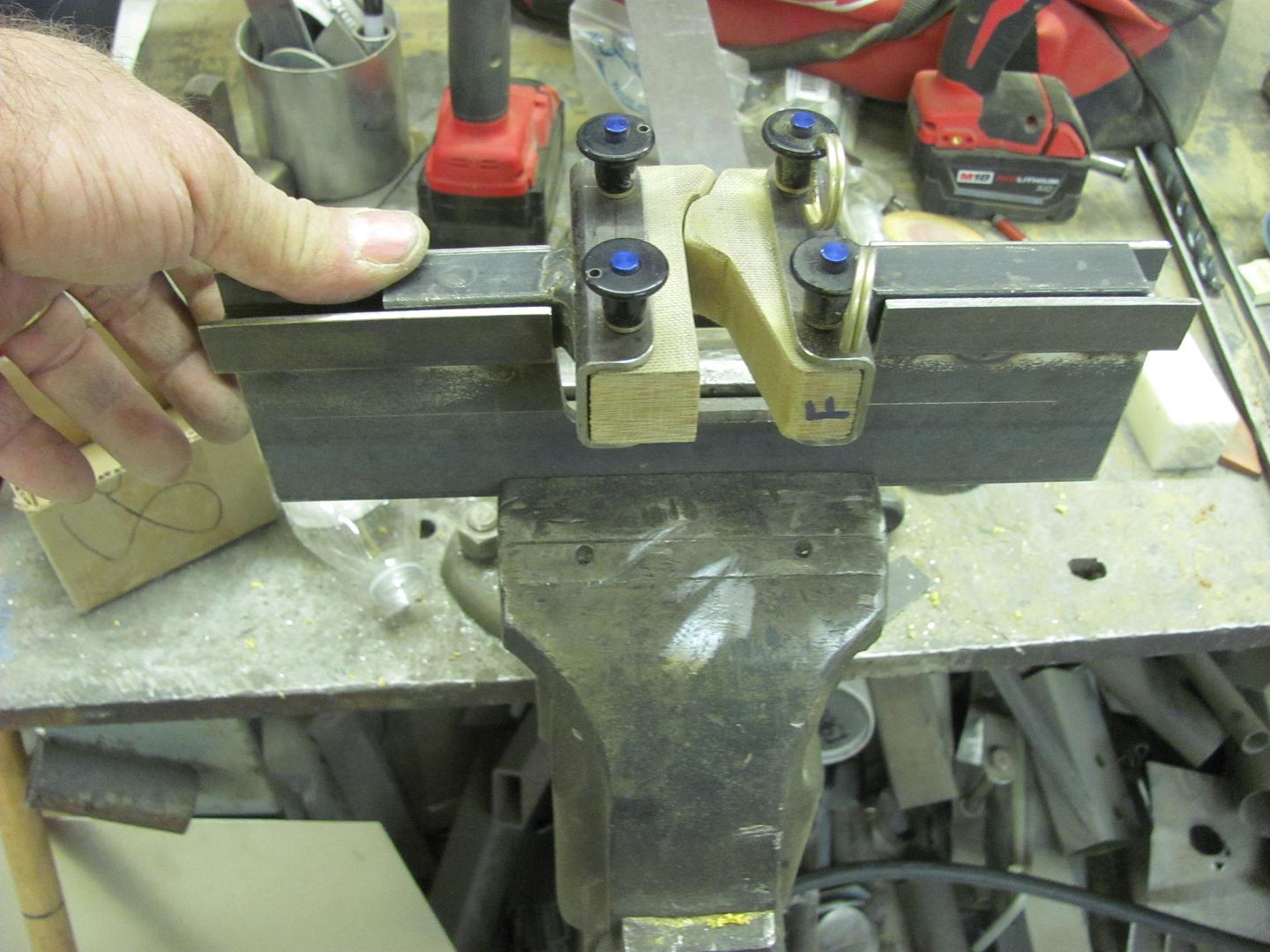

Roadster quarter, making dies for the upper bead detail....

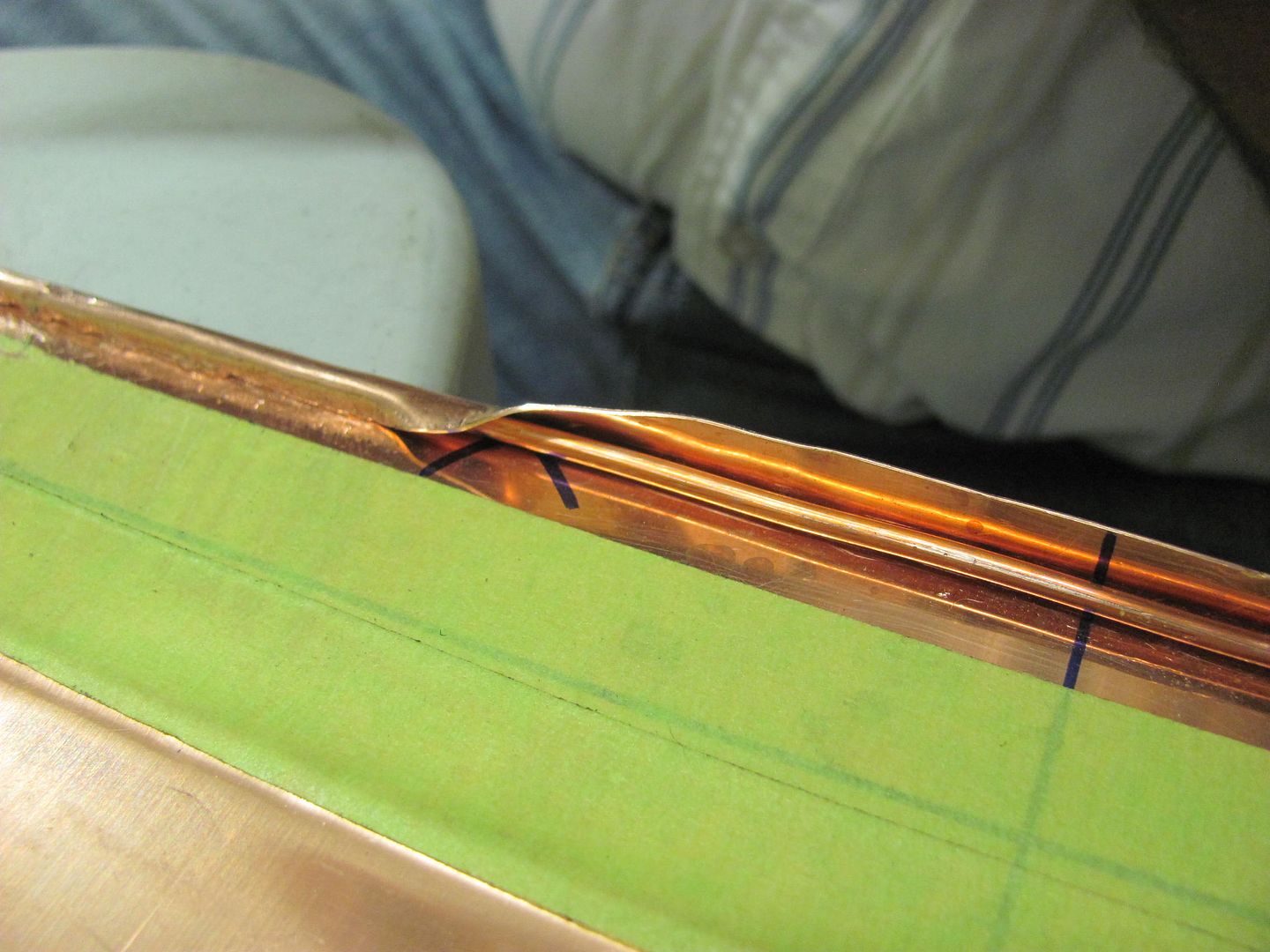

Sharpening the crease

A bit of shrinking....

Test fit...

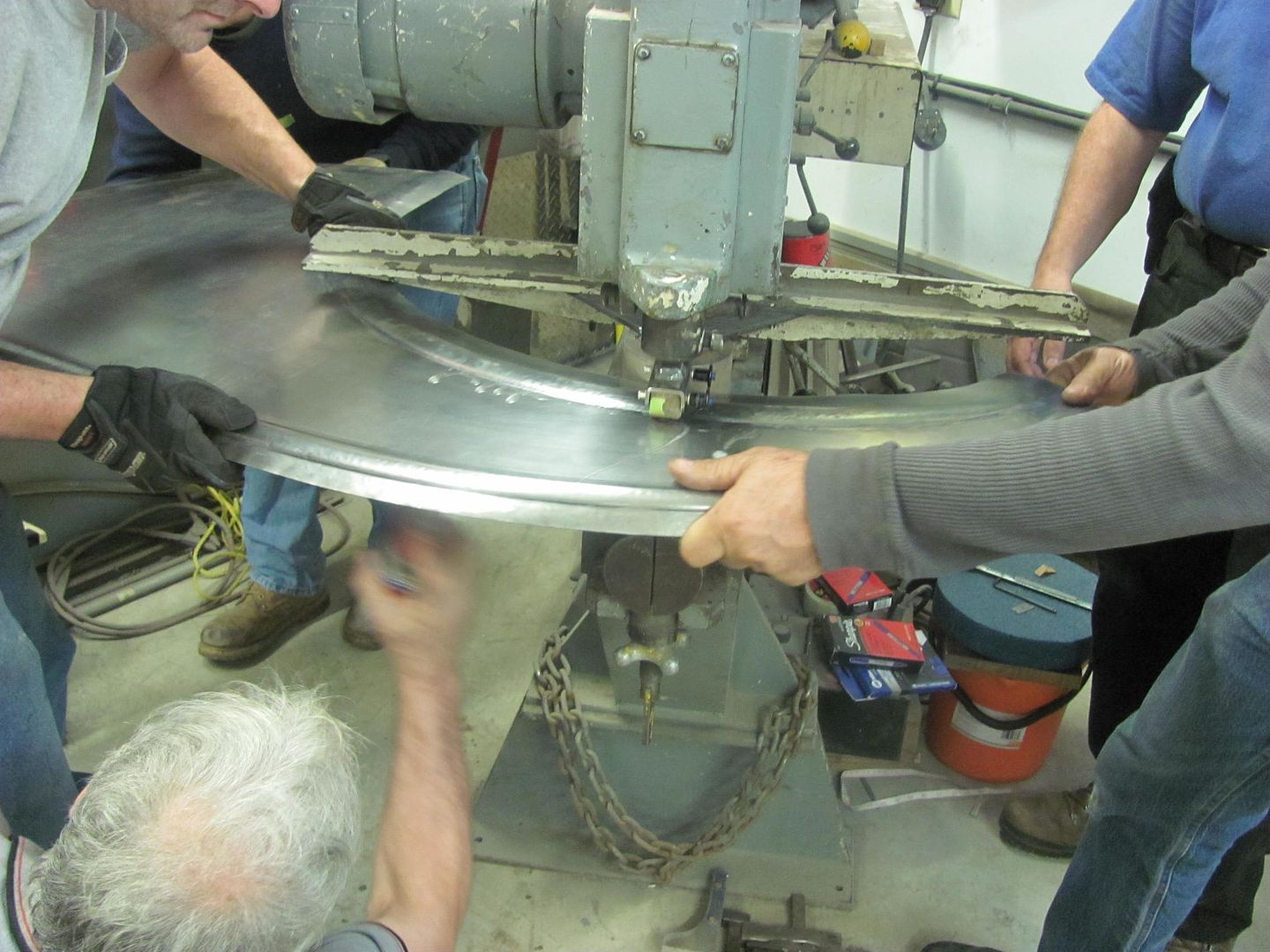

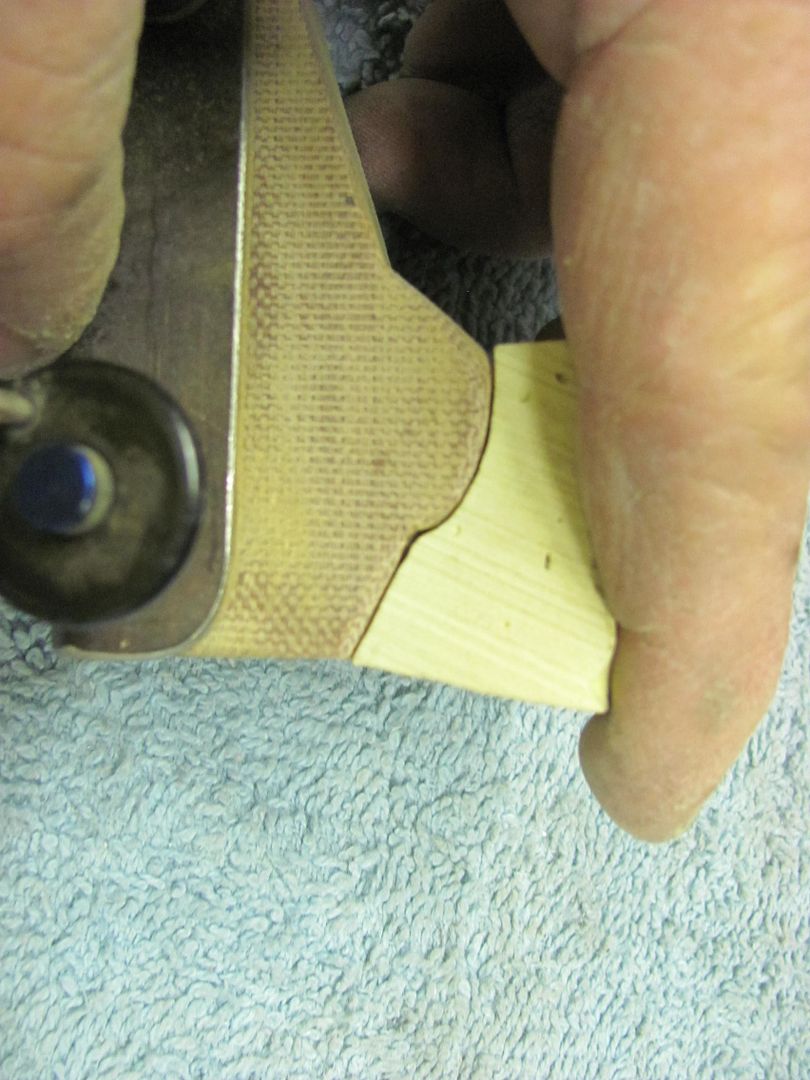

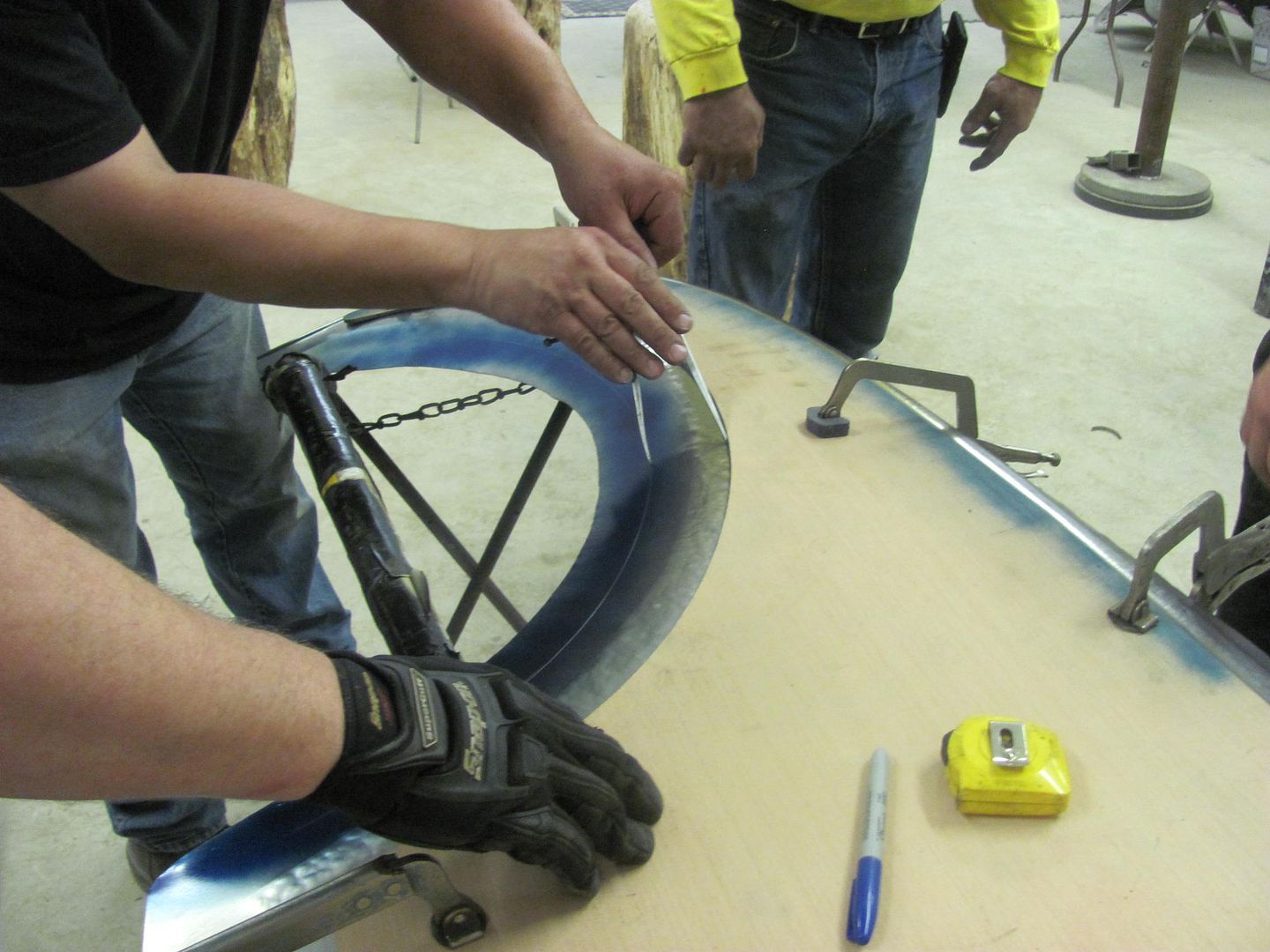

Marking for trimming the wheel opening...

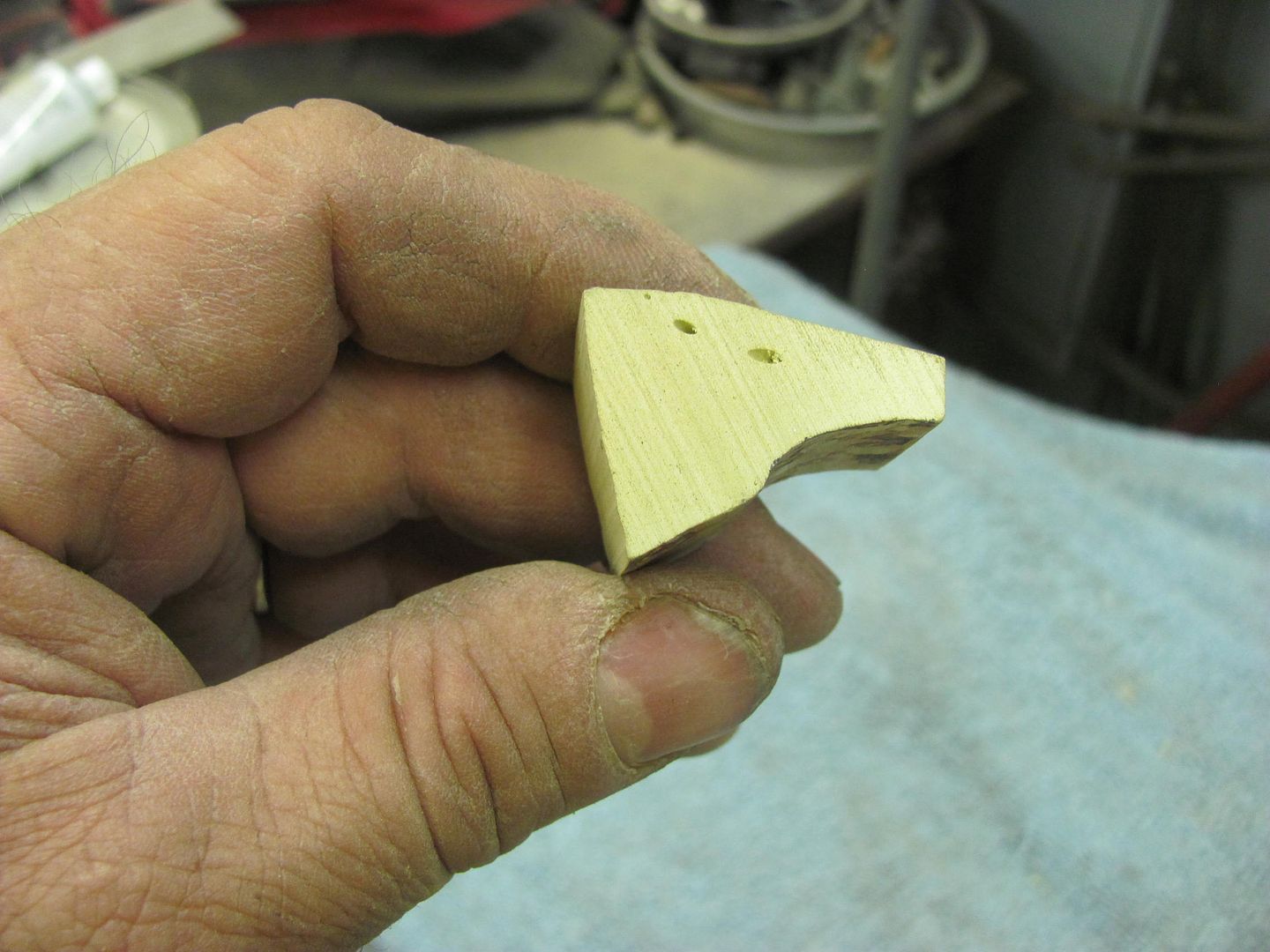

Inside radius backstop

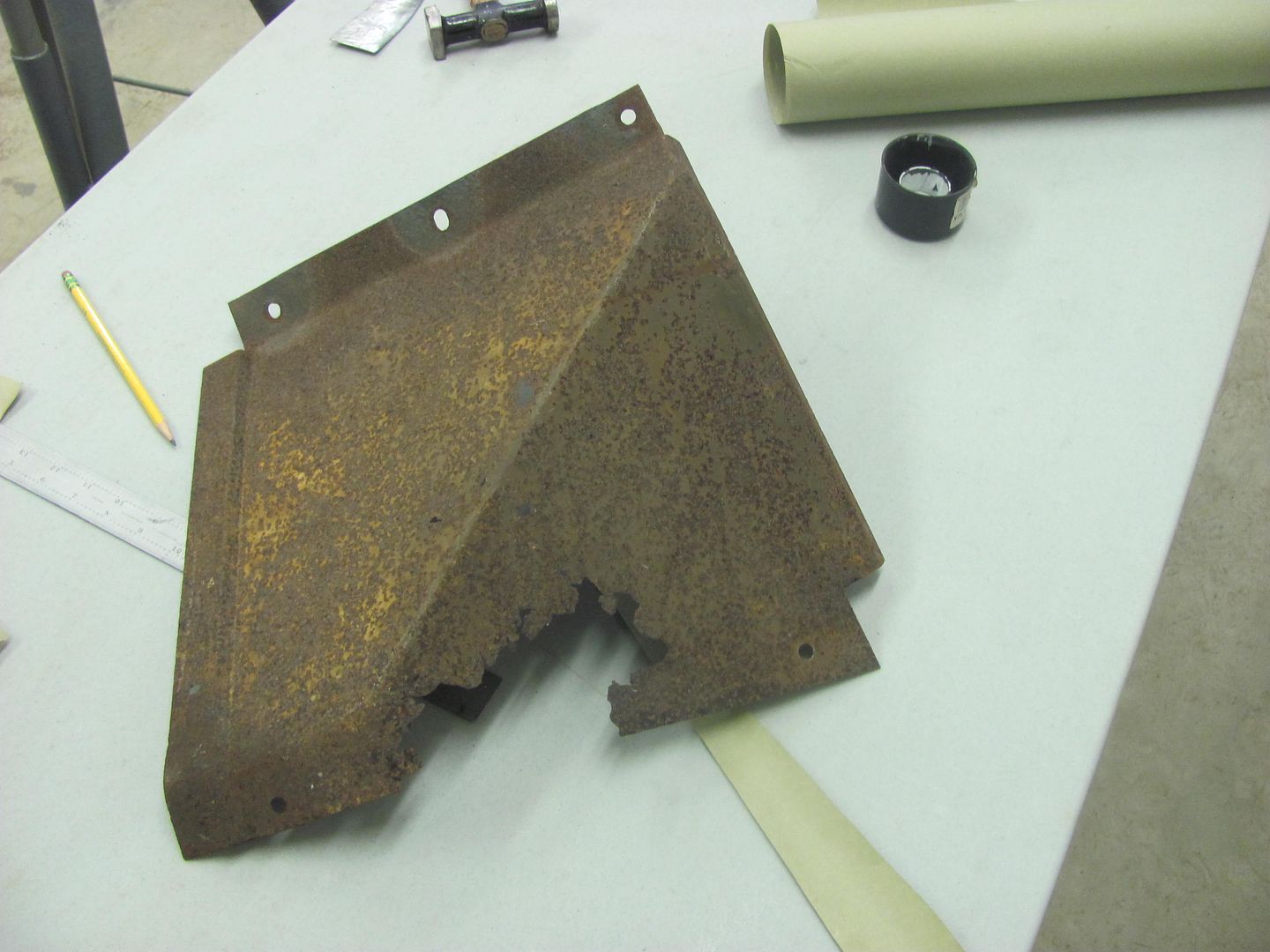

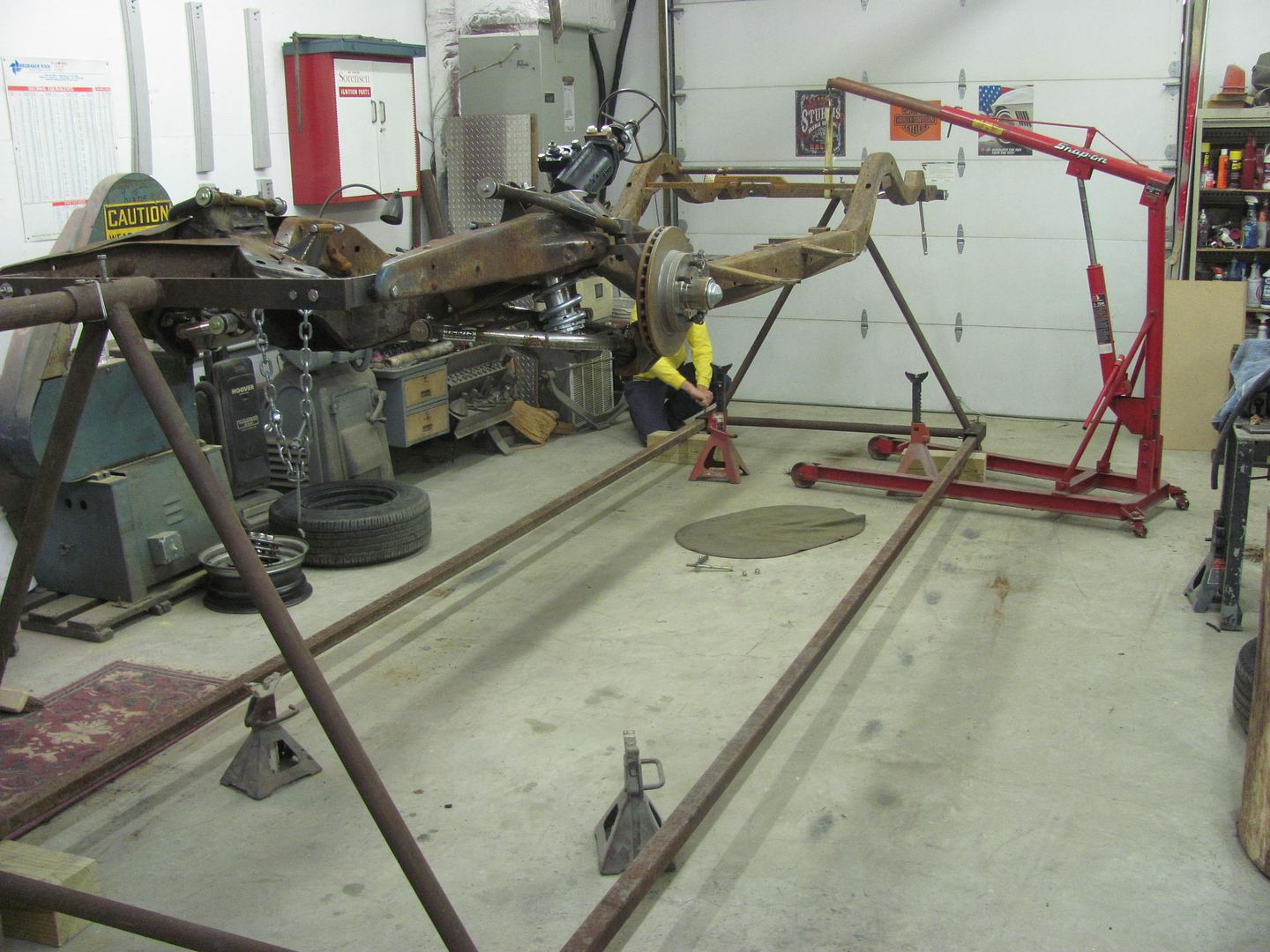

Scooter fender...

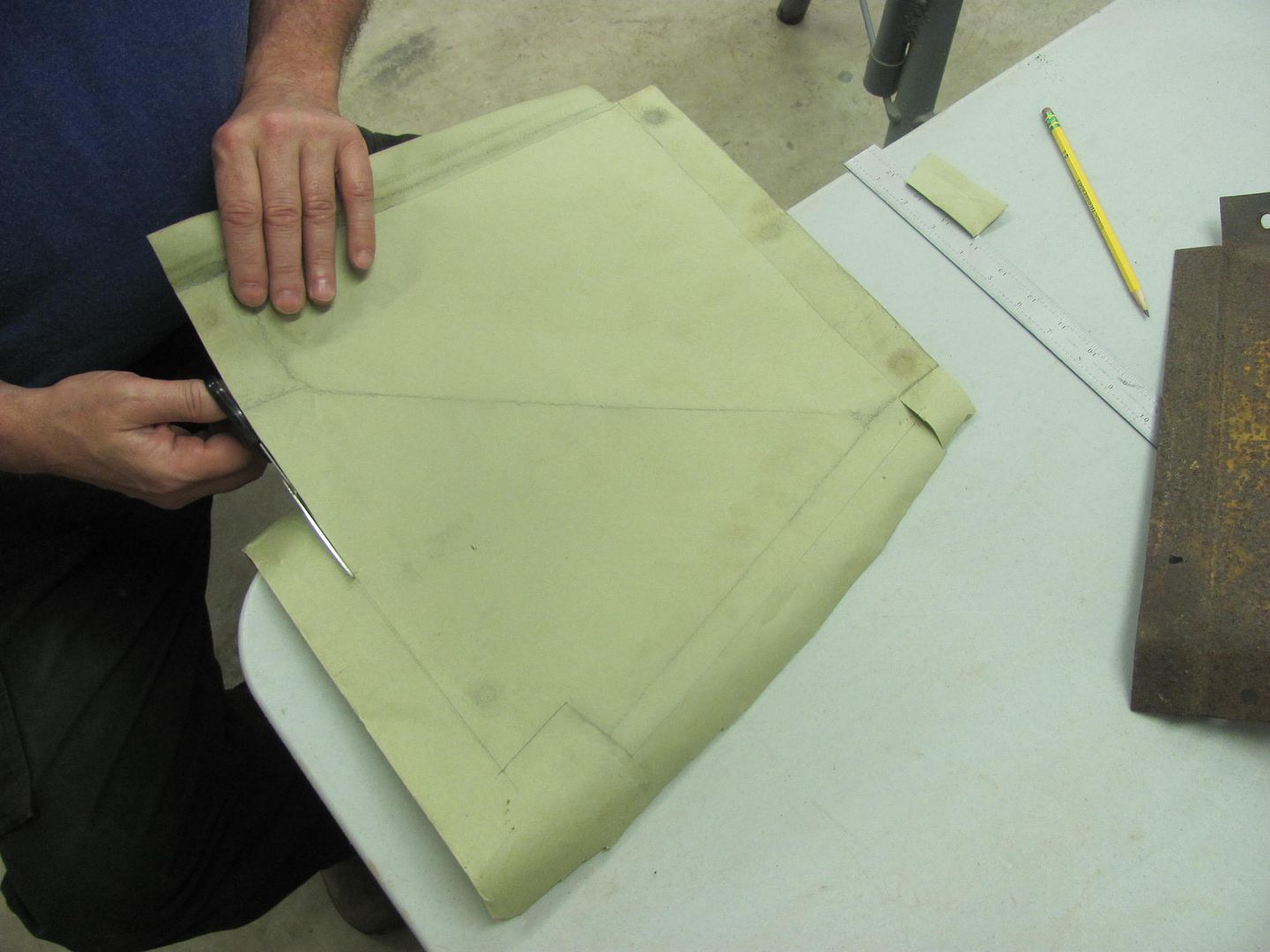

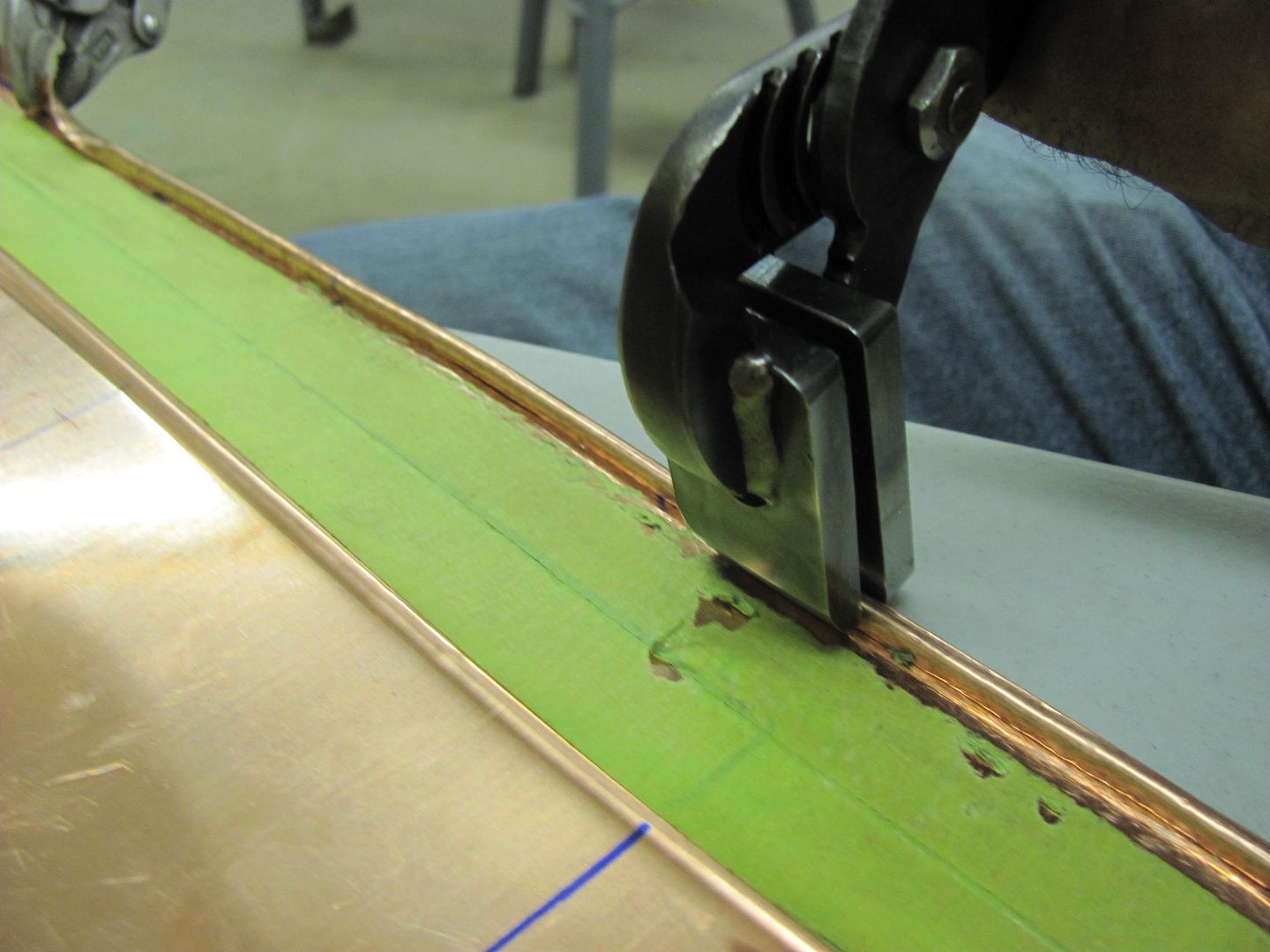

Trimming...

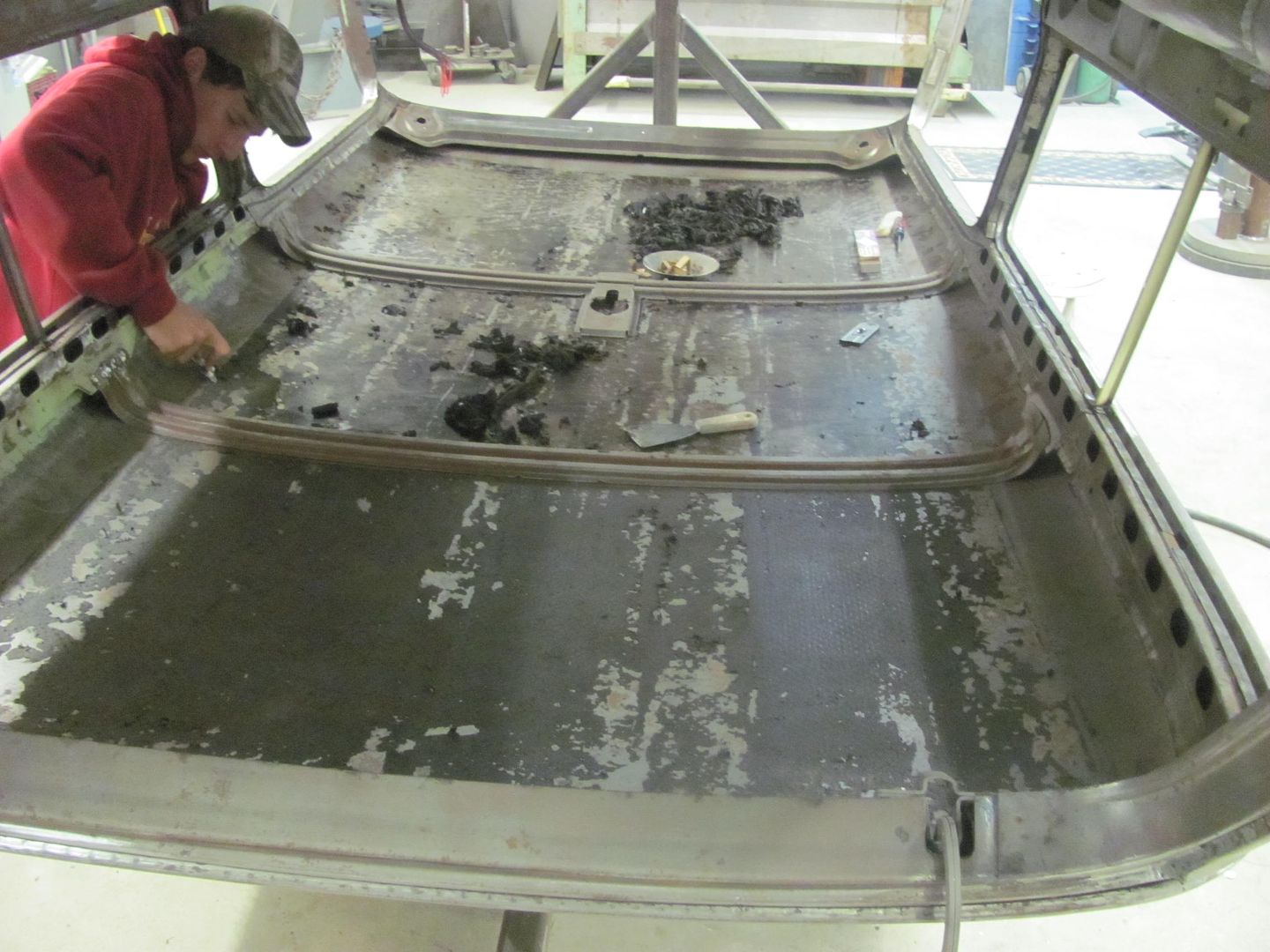

Prepping for Sport Coupe door skin removal

We took a short break for a Maryland treat...

of course, using only the correct utensils....

Blocking the top section of the roadster quarter.....

Reply With Quote

Reply With Quote