This evening while we had painted parts still lounging in the booth, we took some time to clean up and put tools away..... hey, there's that welding table!

And found a new location for the ewheel.. Still gives plenty of room for access to the parts bins and gets it out of the way elsewhere in the shop..

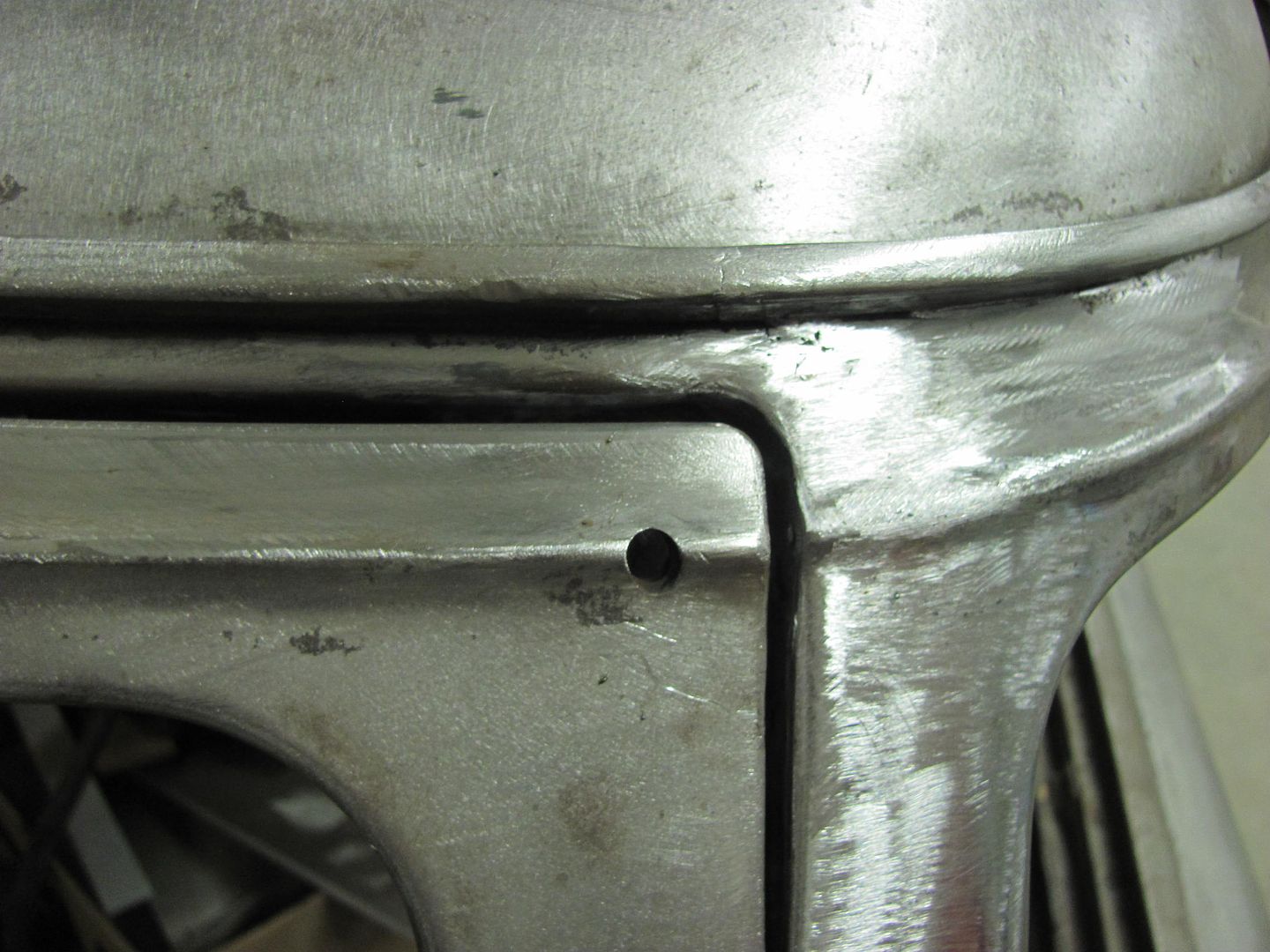

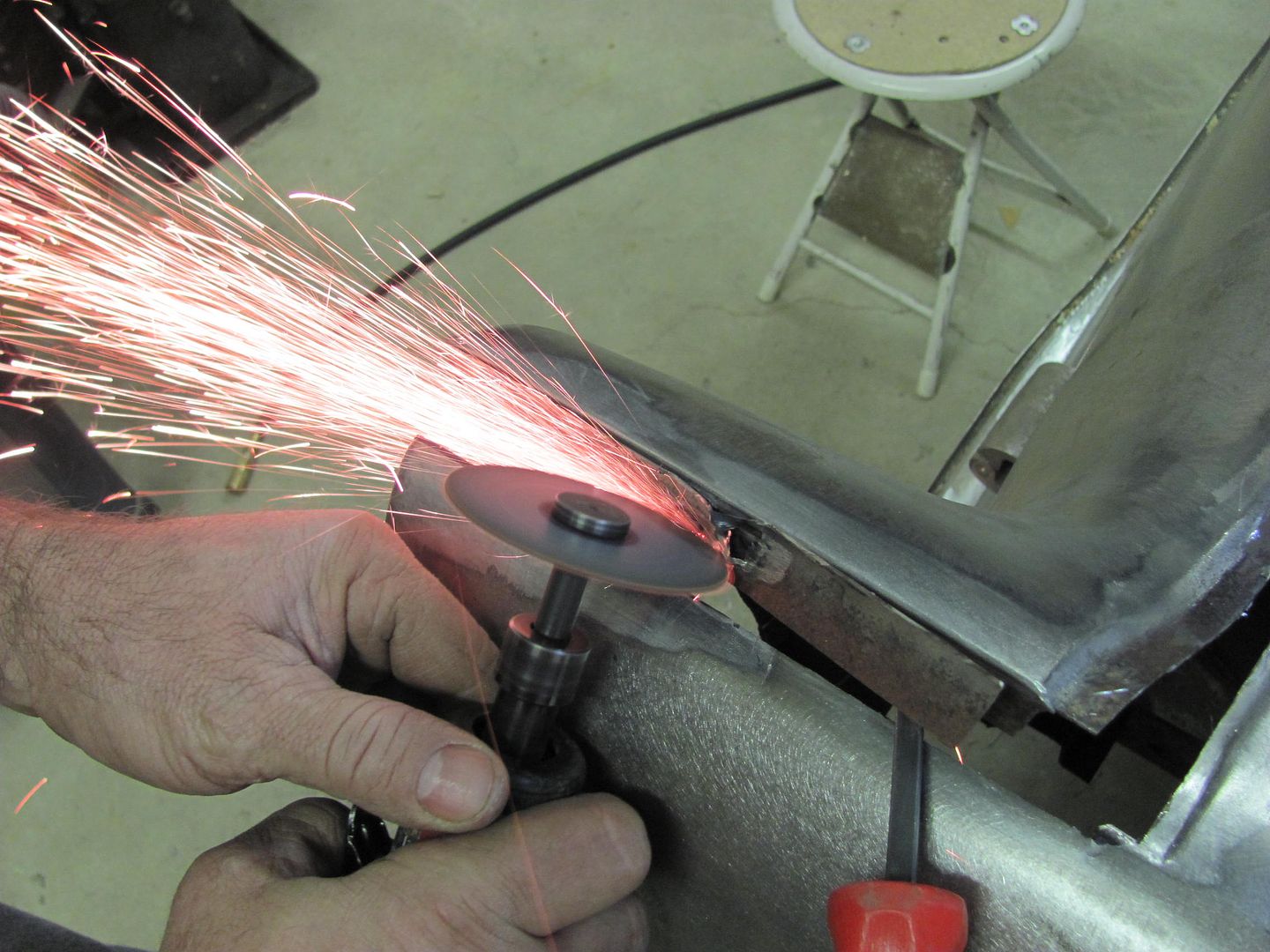

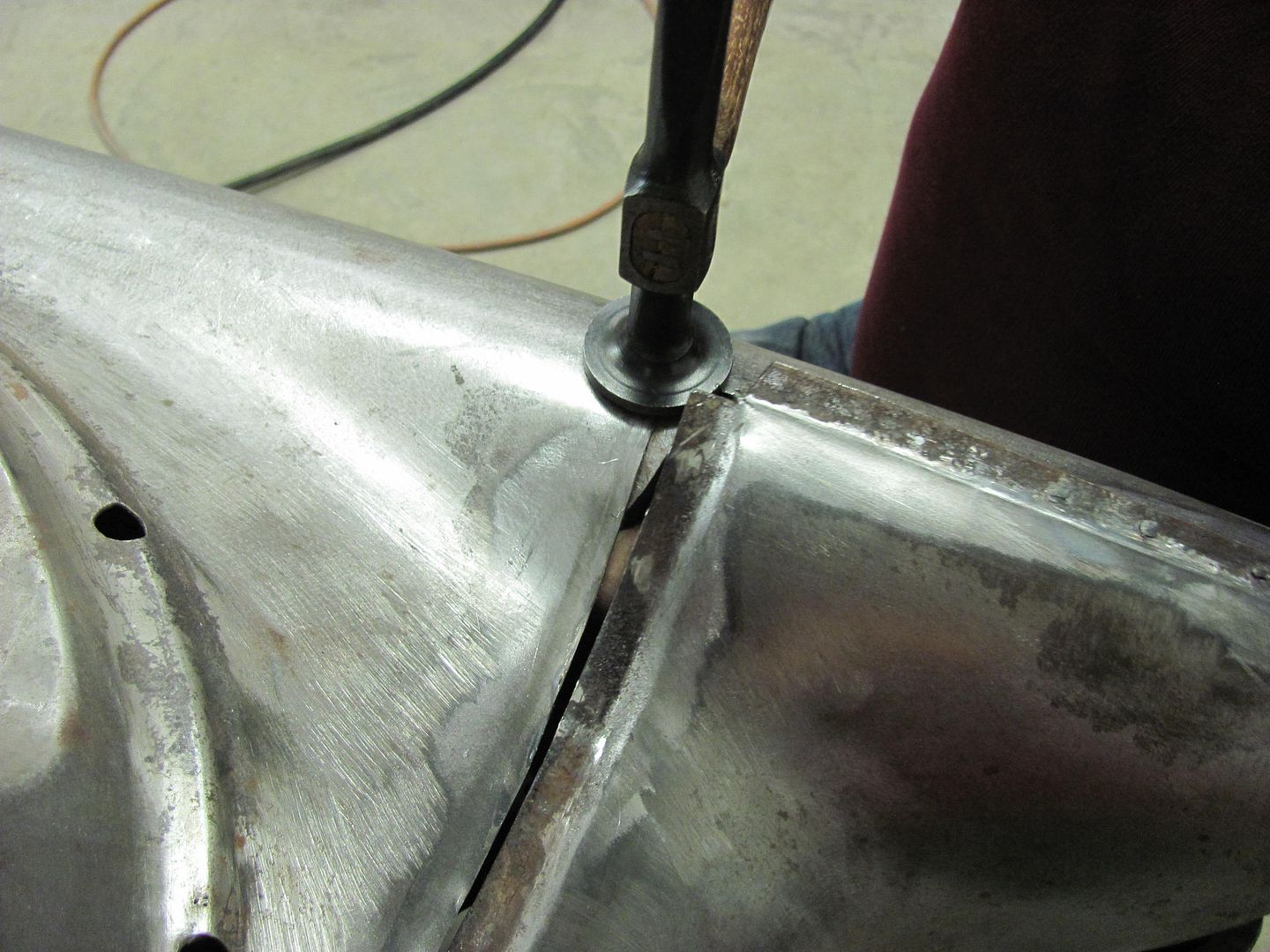

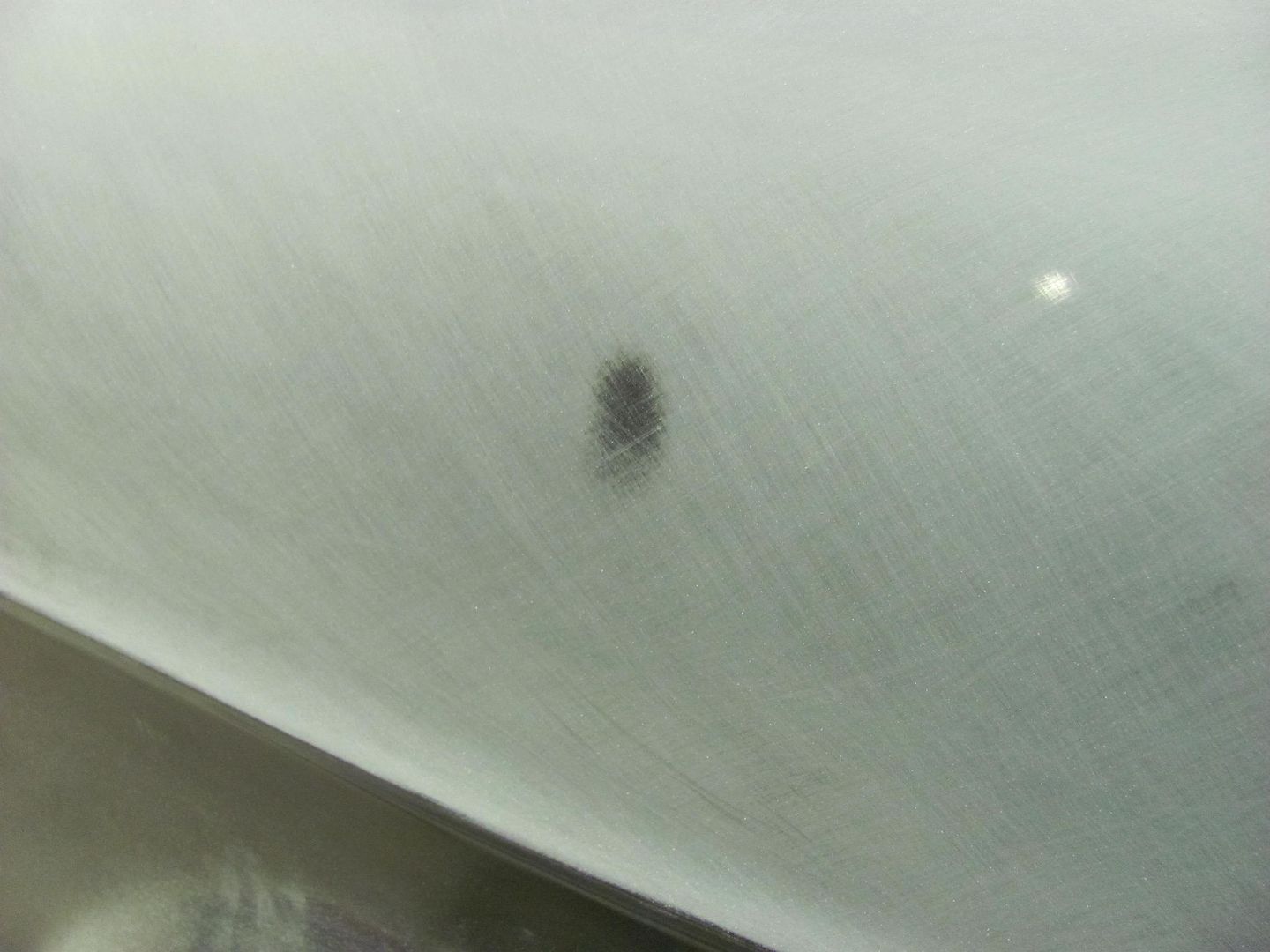

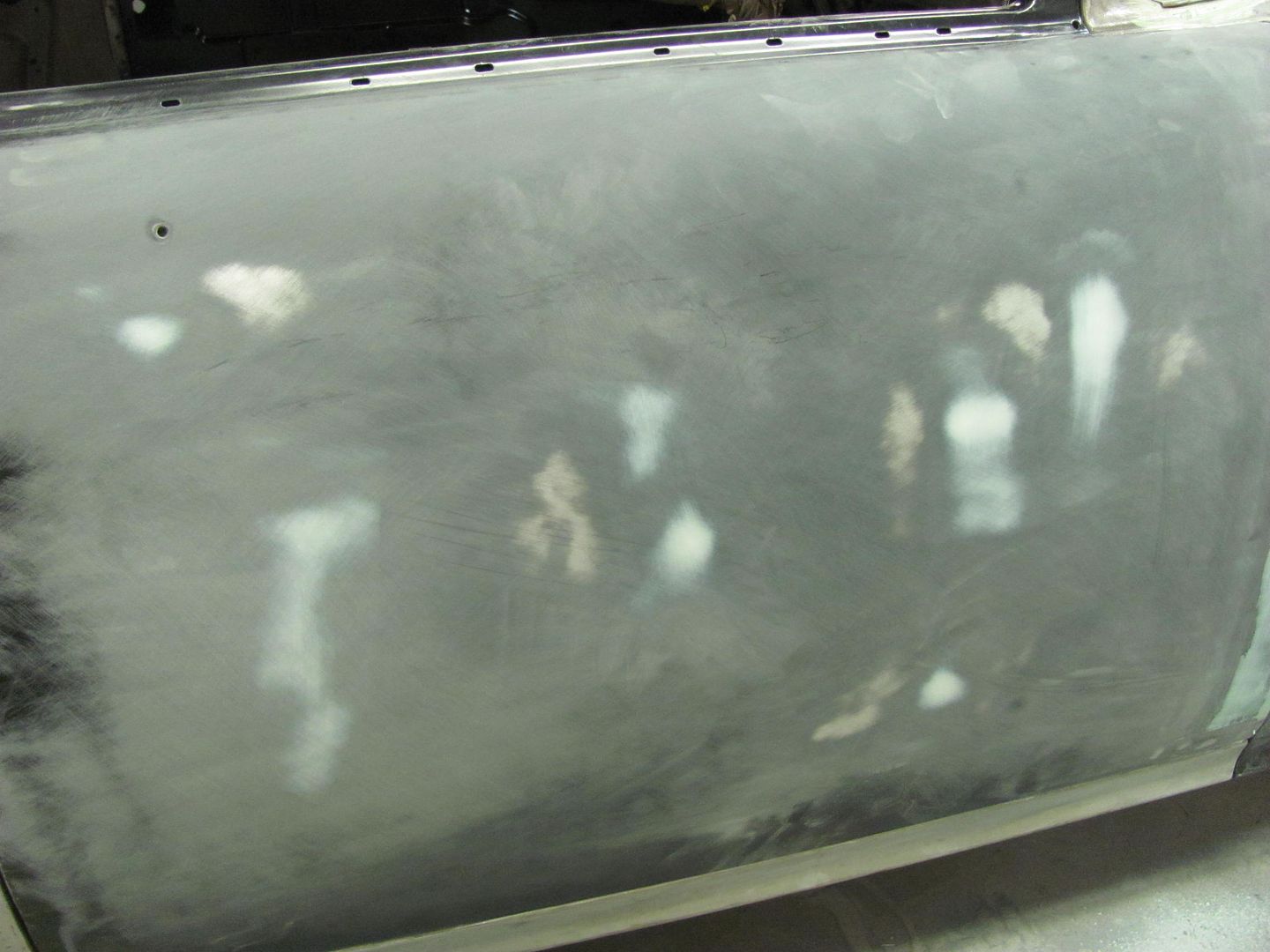

After that we worked to fix some pin holes along the passenger quarter's weld.. using a light from the back side to show the pin holes...

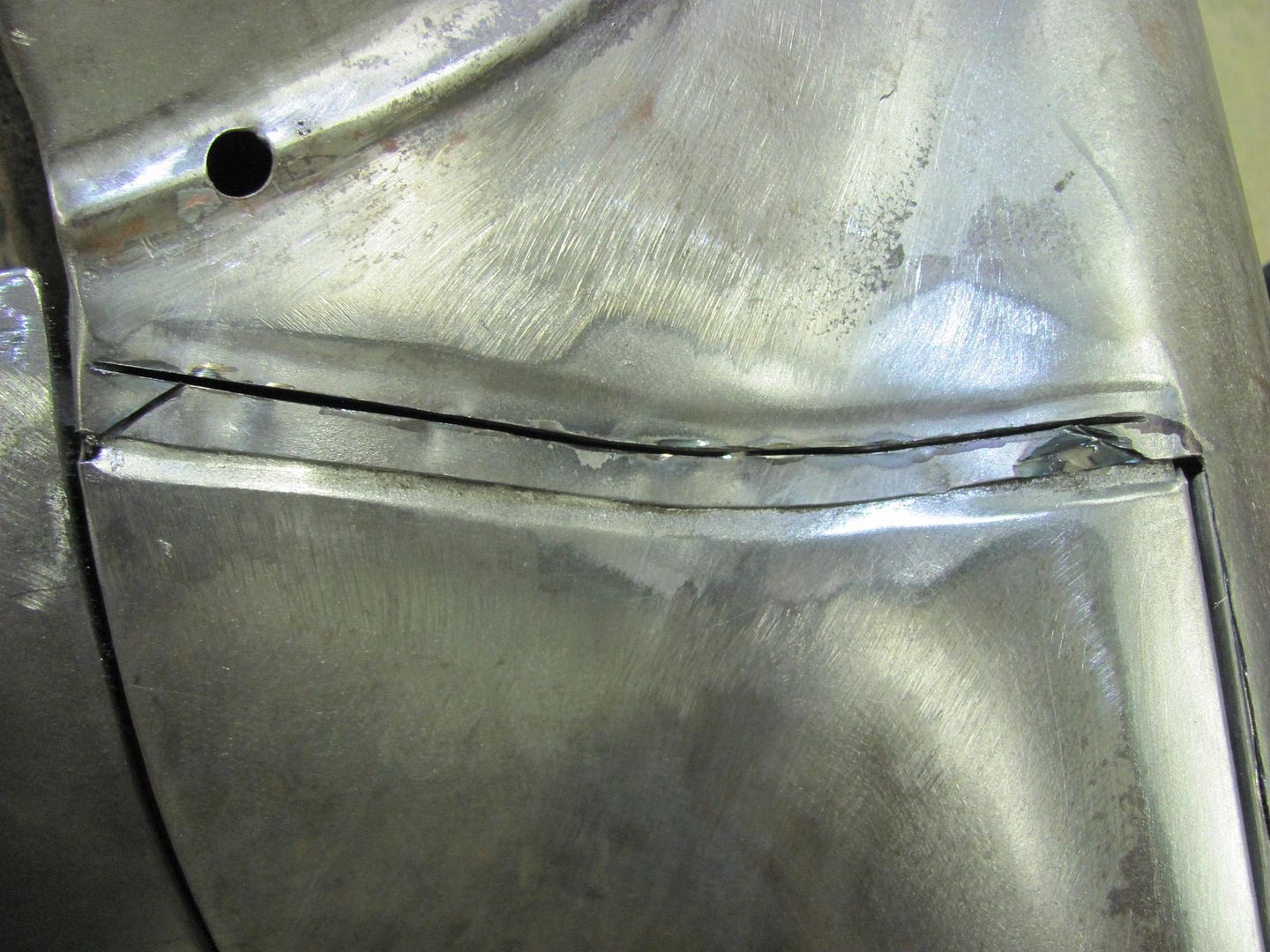

....and this one was a pit from the back side, more of the dreaded dirt thrown from the rear tire causing rust....

Reply With Quote

Reply With Quote