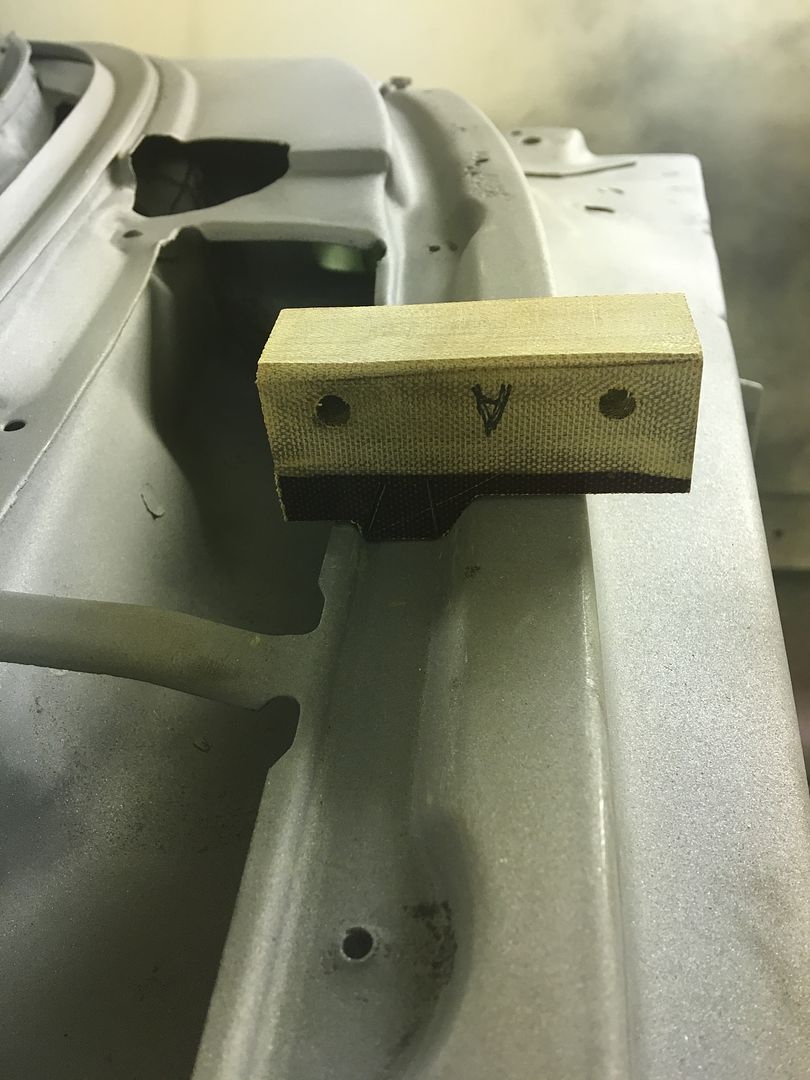

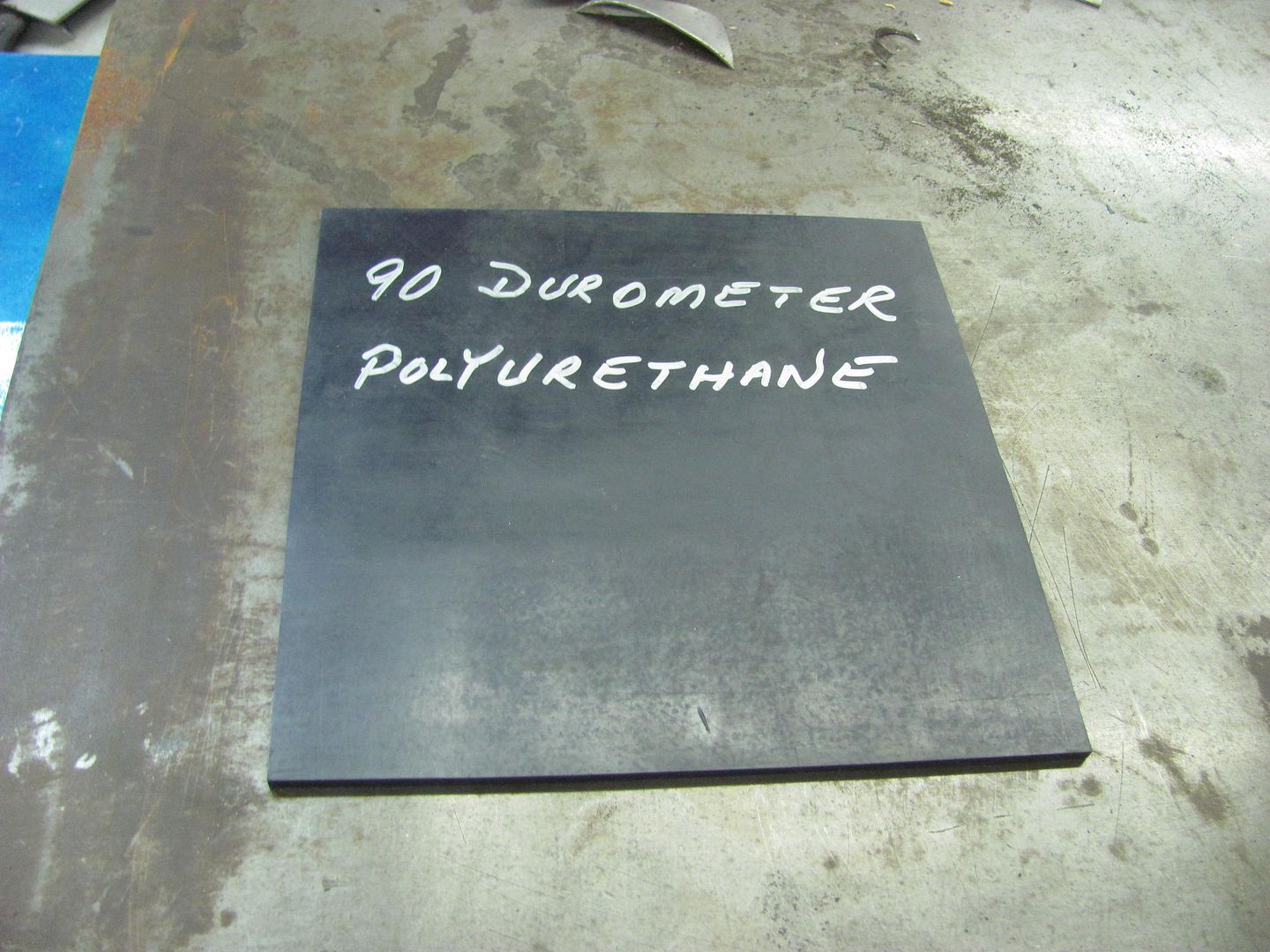

Well with a nice radius on the face of the glove box door skin, we now need a flat area for the lock cylinder. Since I had a piece of Polyurethane here from the care package Rich B had sent me, it seemed the right tool for the job.

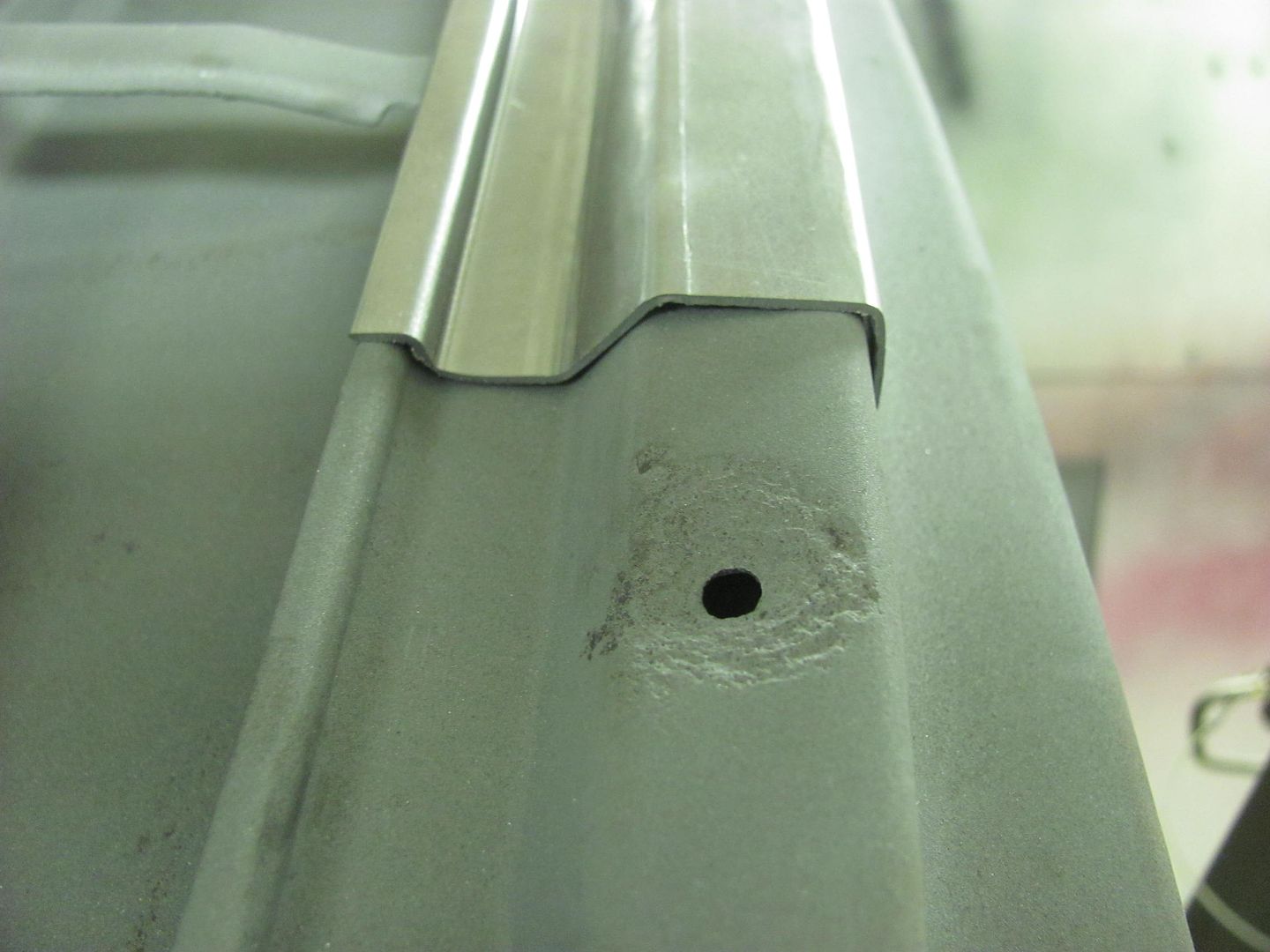

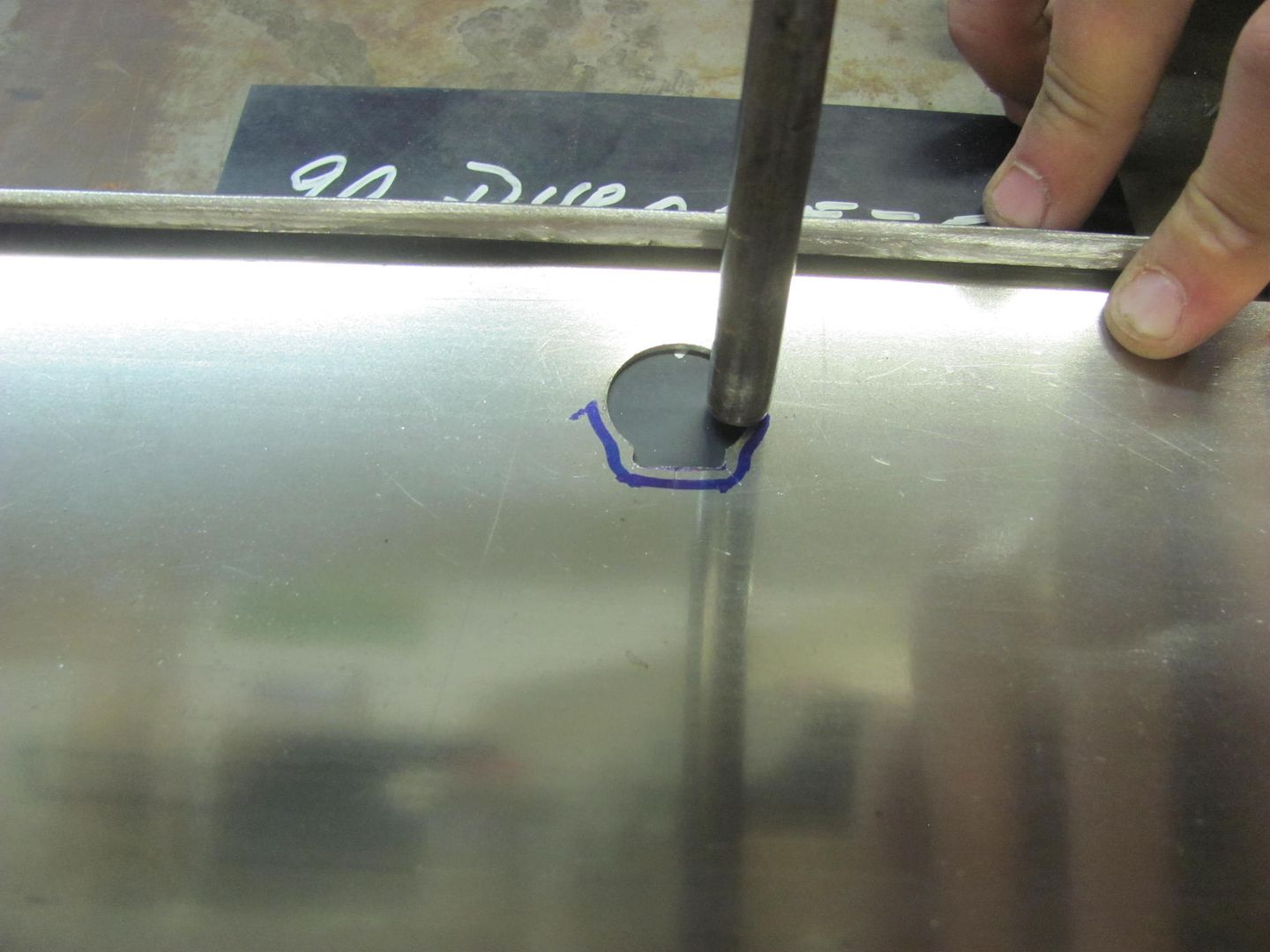

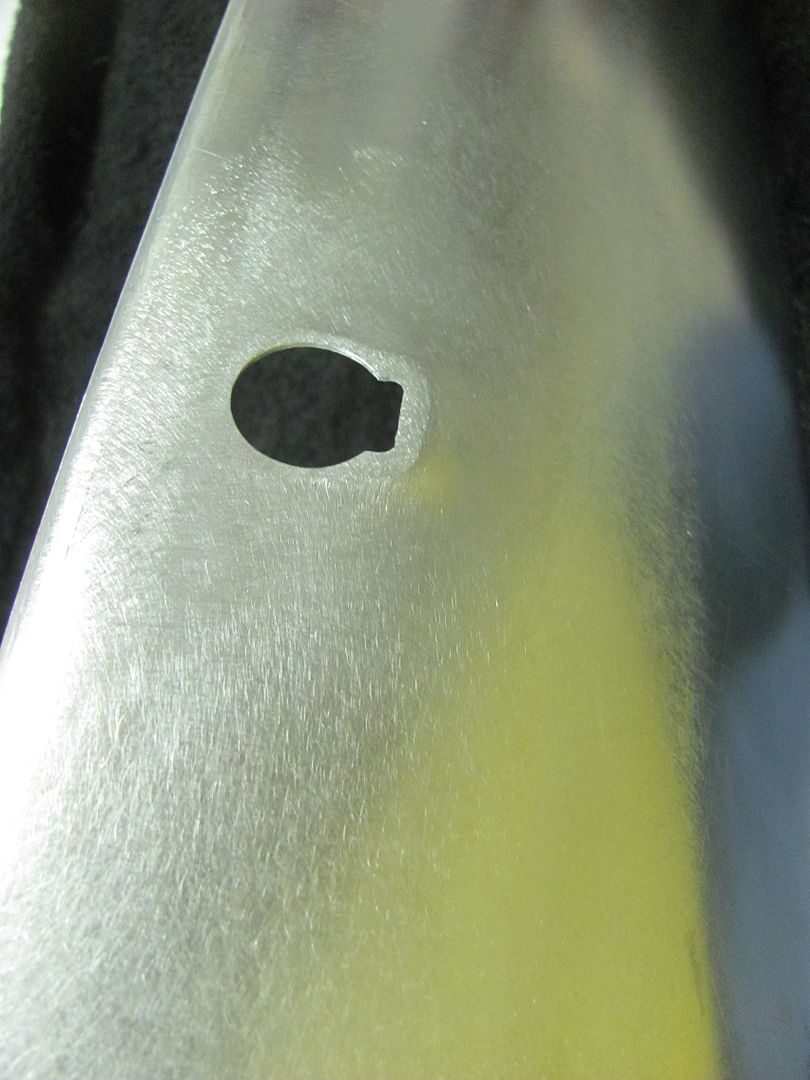

The lock cylinder hole was added using a step drill for the hole and a die grinder for the notch.

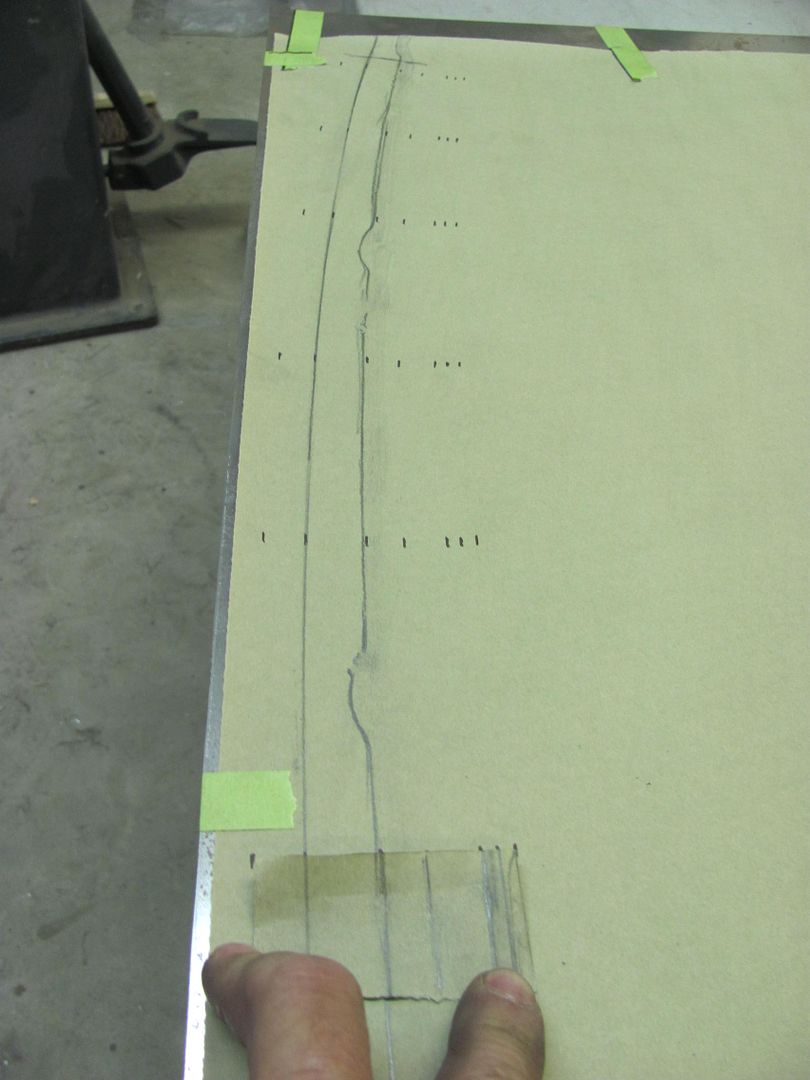

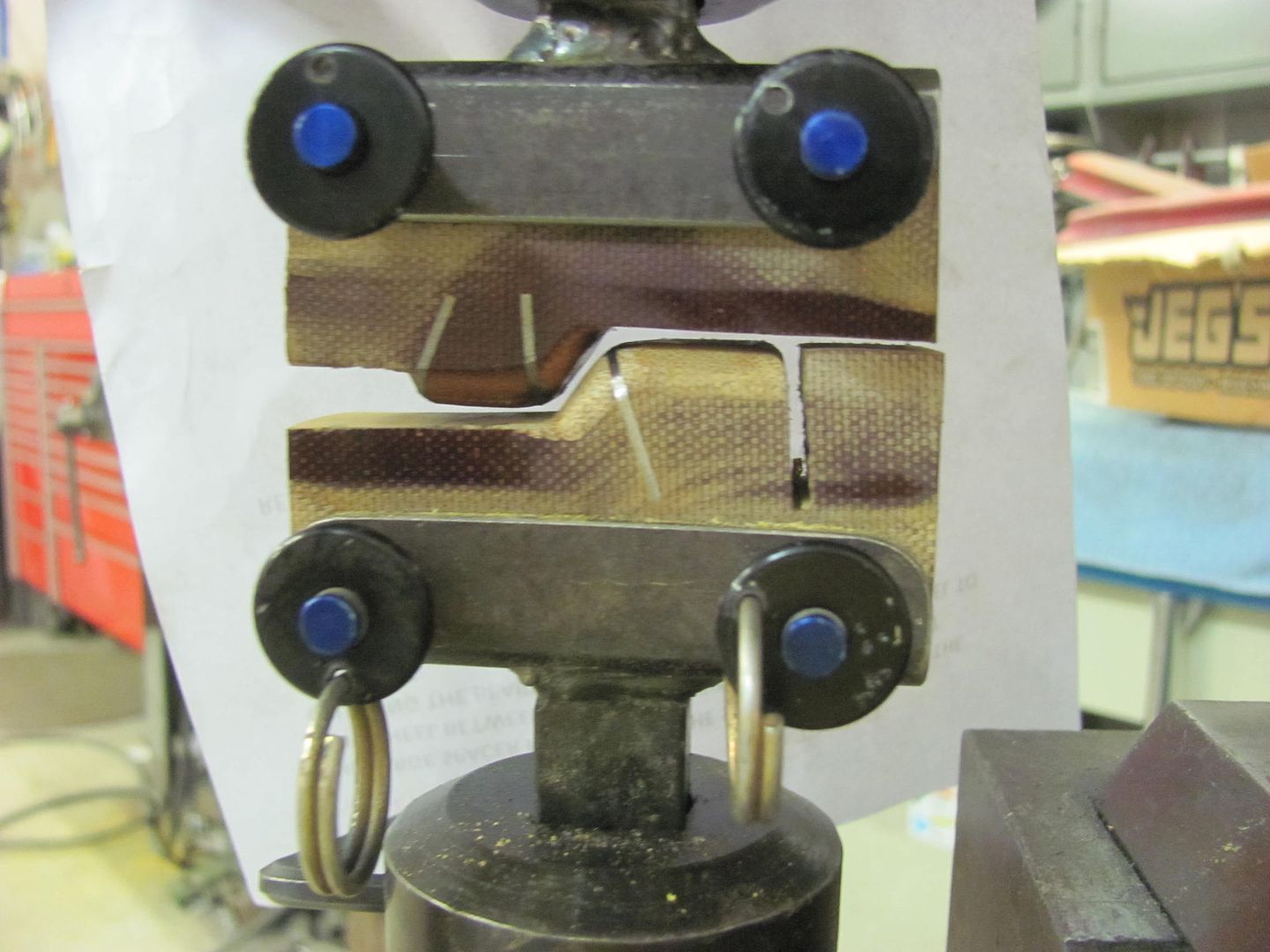

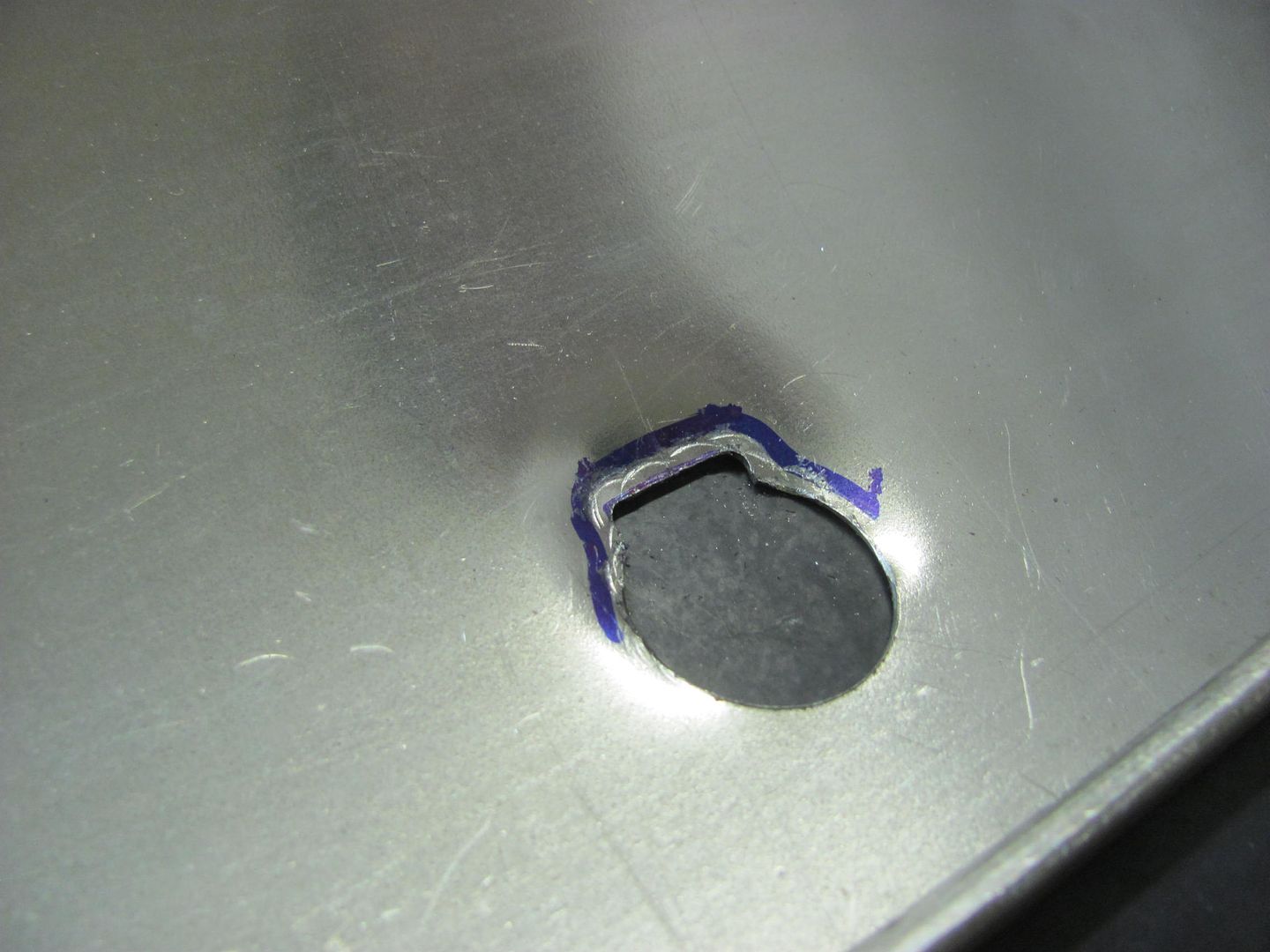

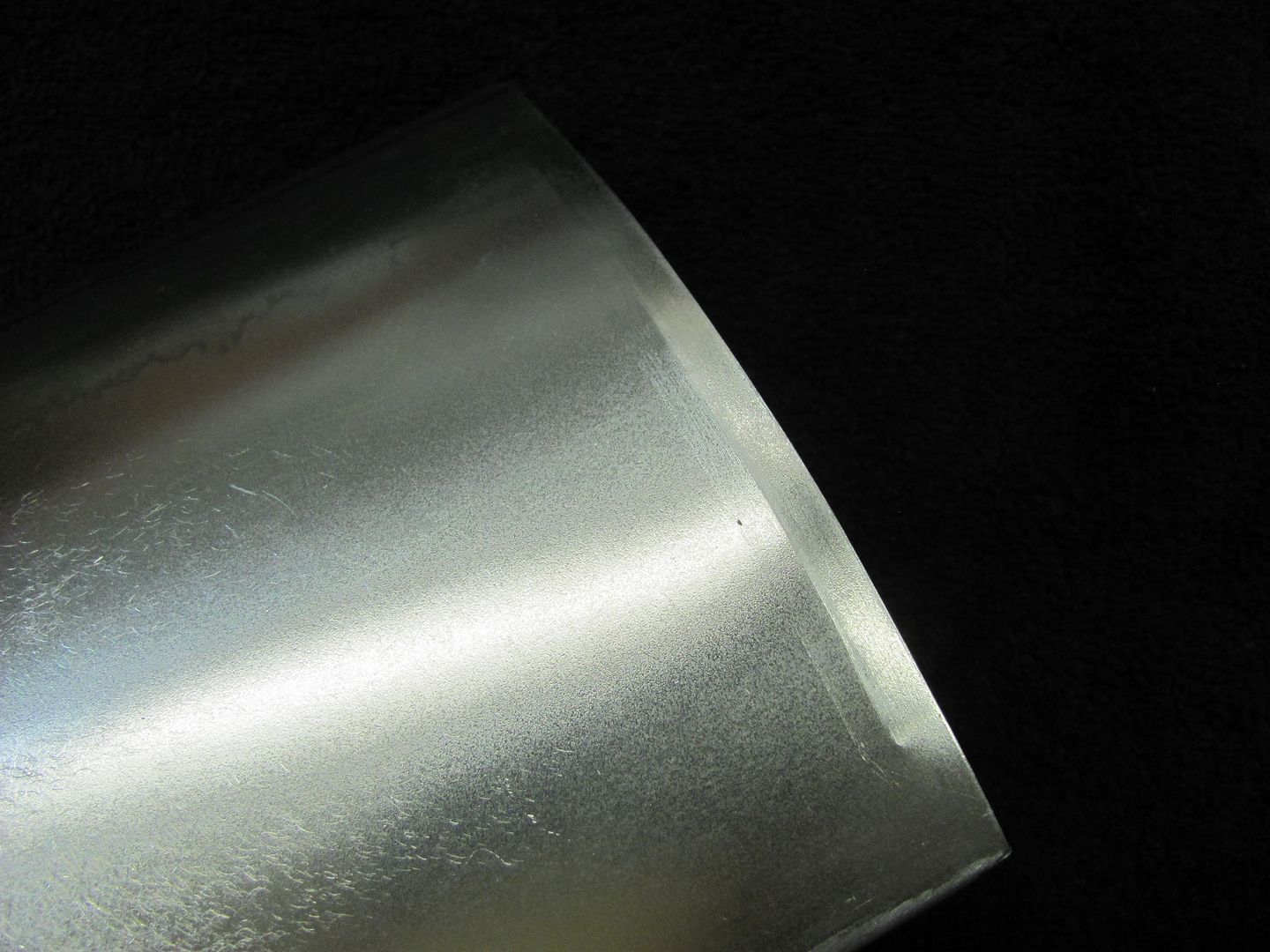

A punch is used to add the needed stretch to provide the flat area..

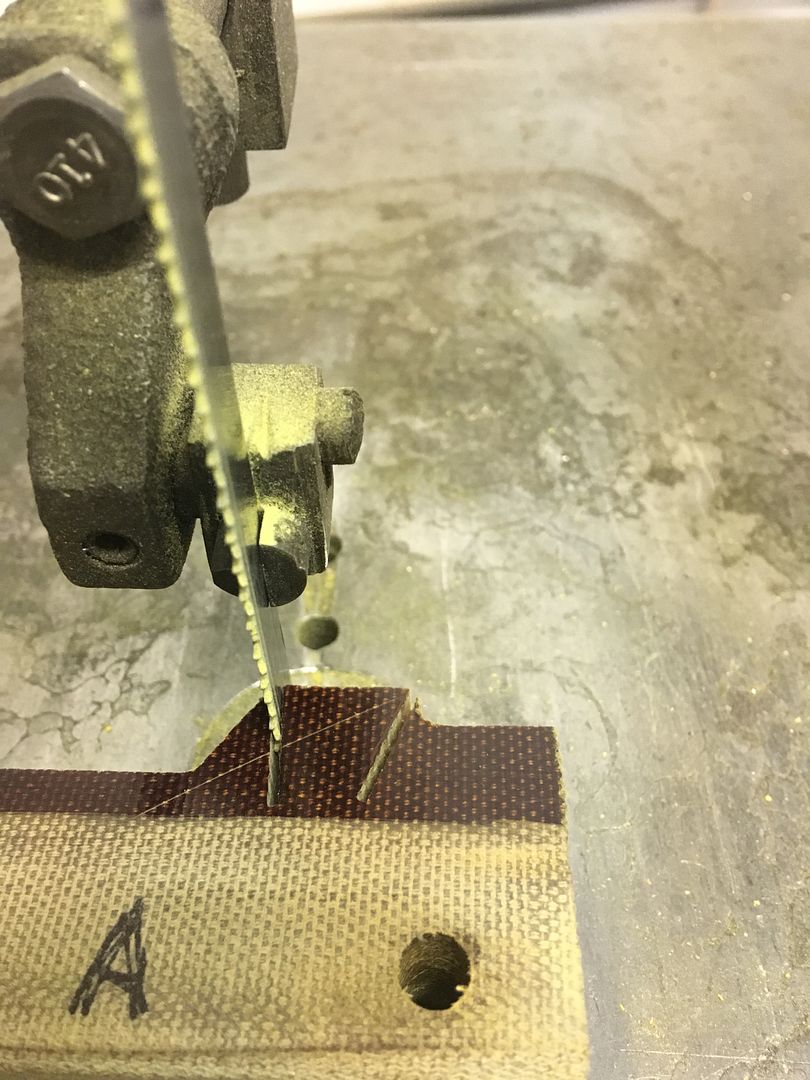

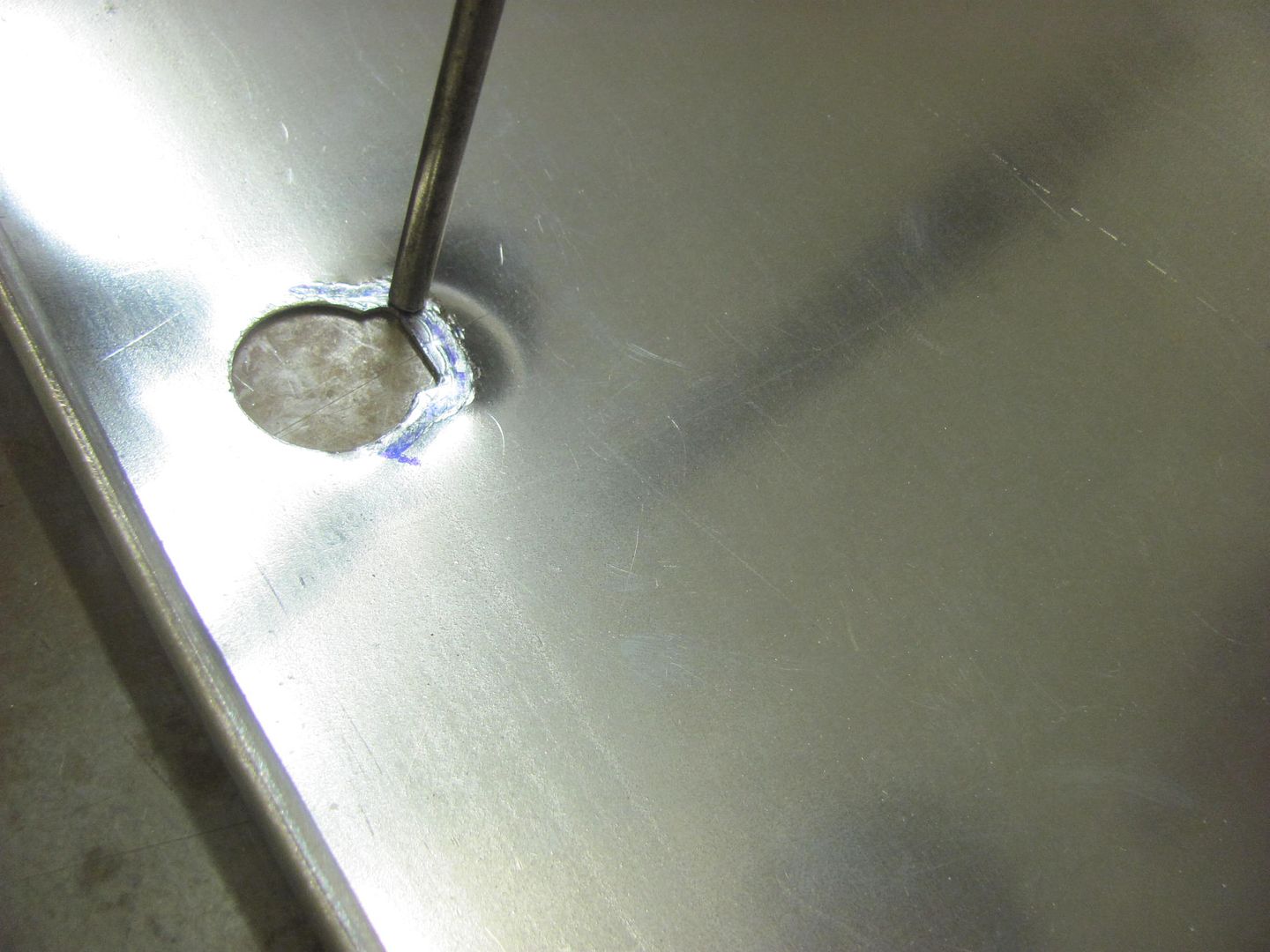

Starting to take shape..

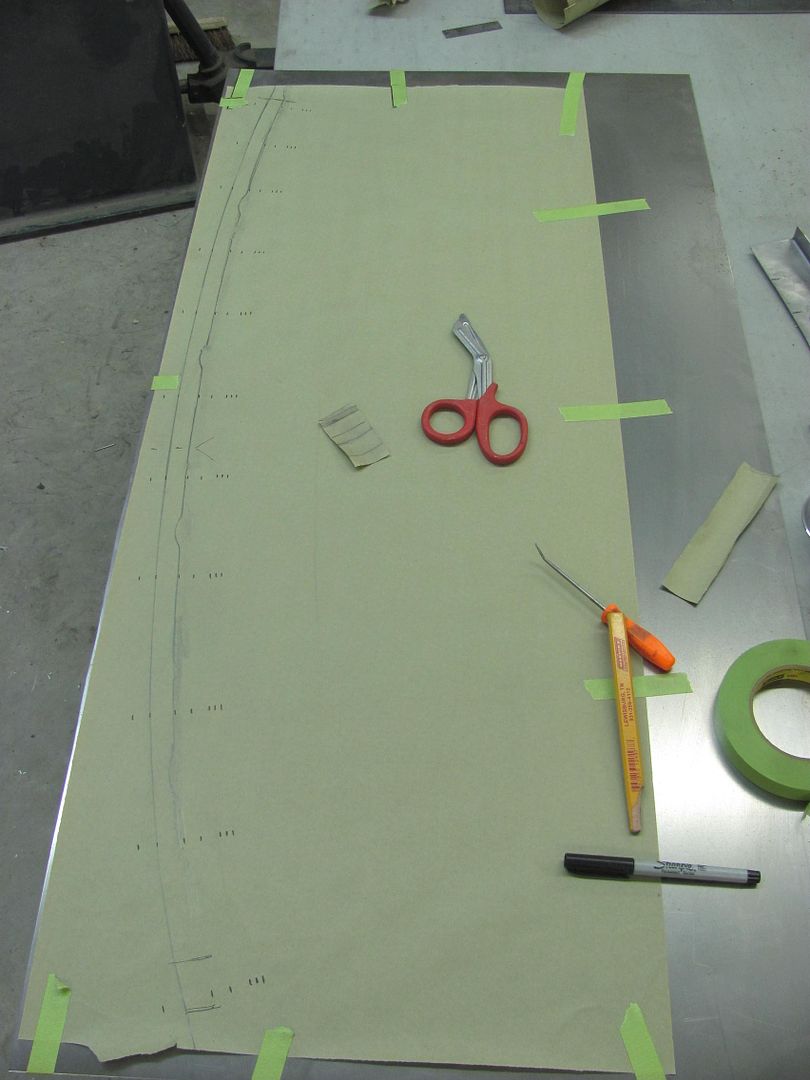

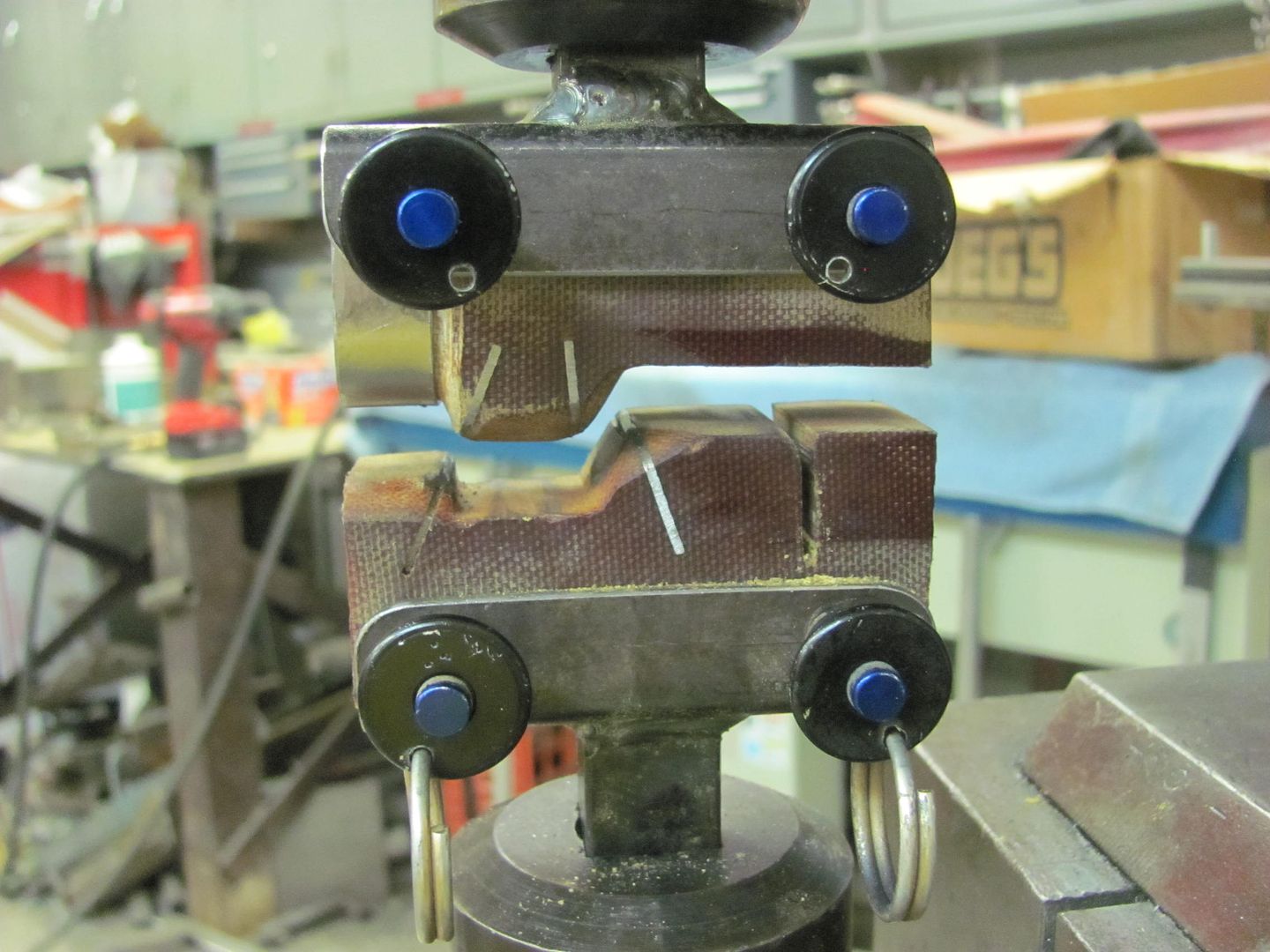

Some fine tuning of the detail...

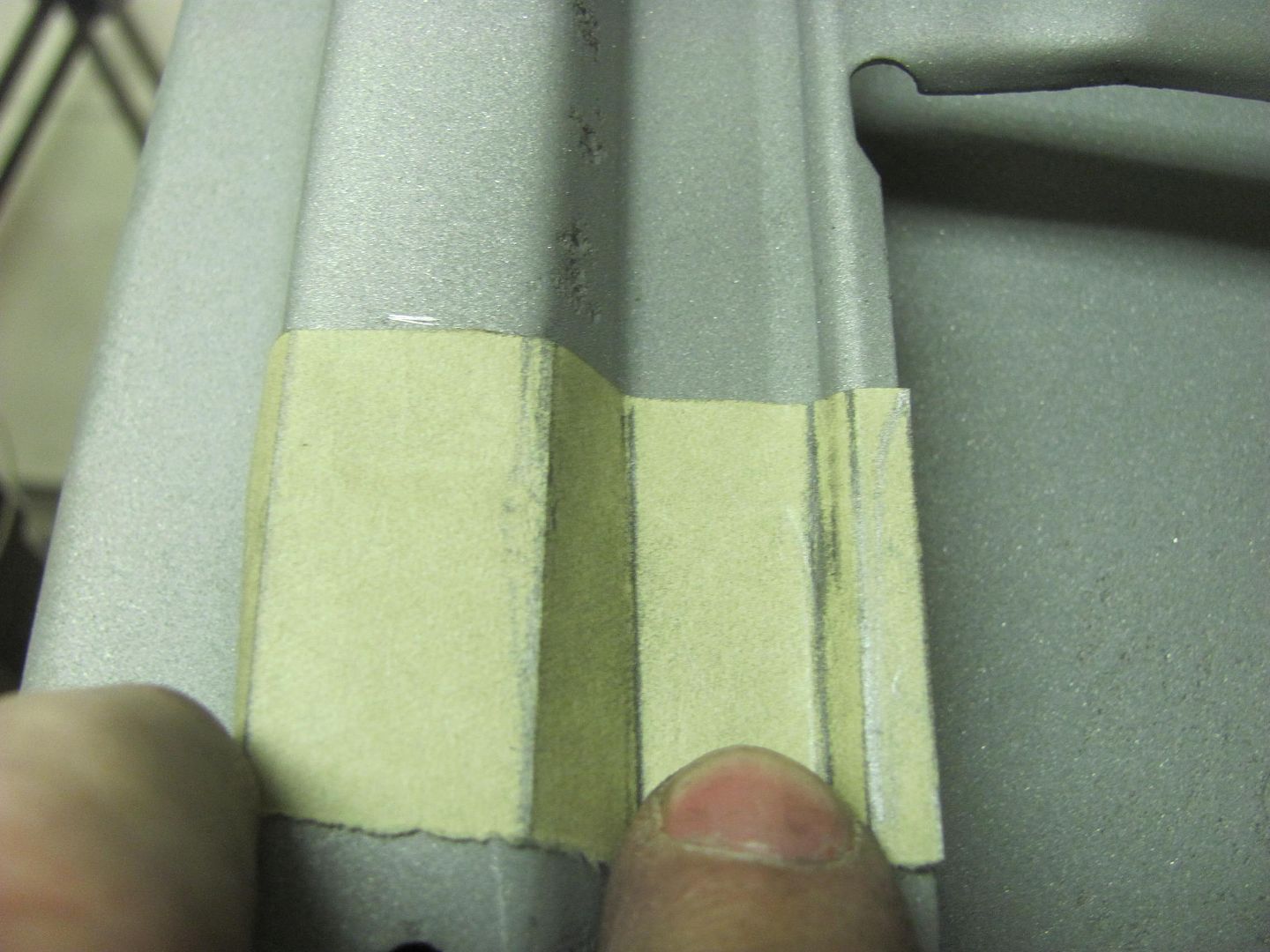

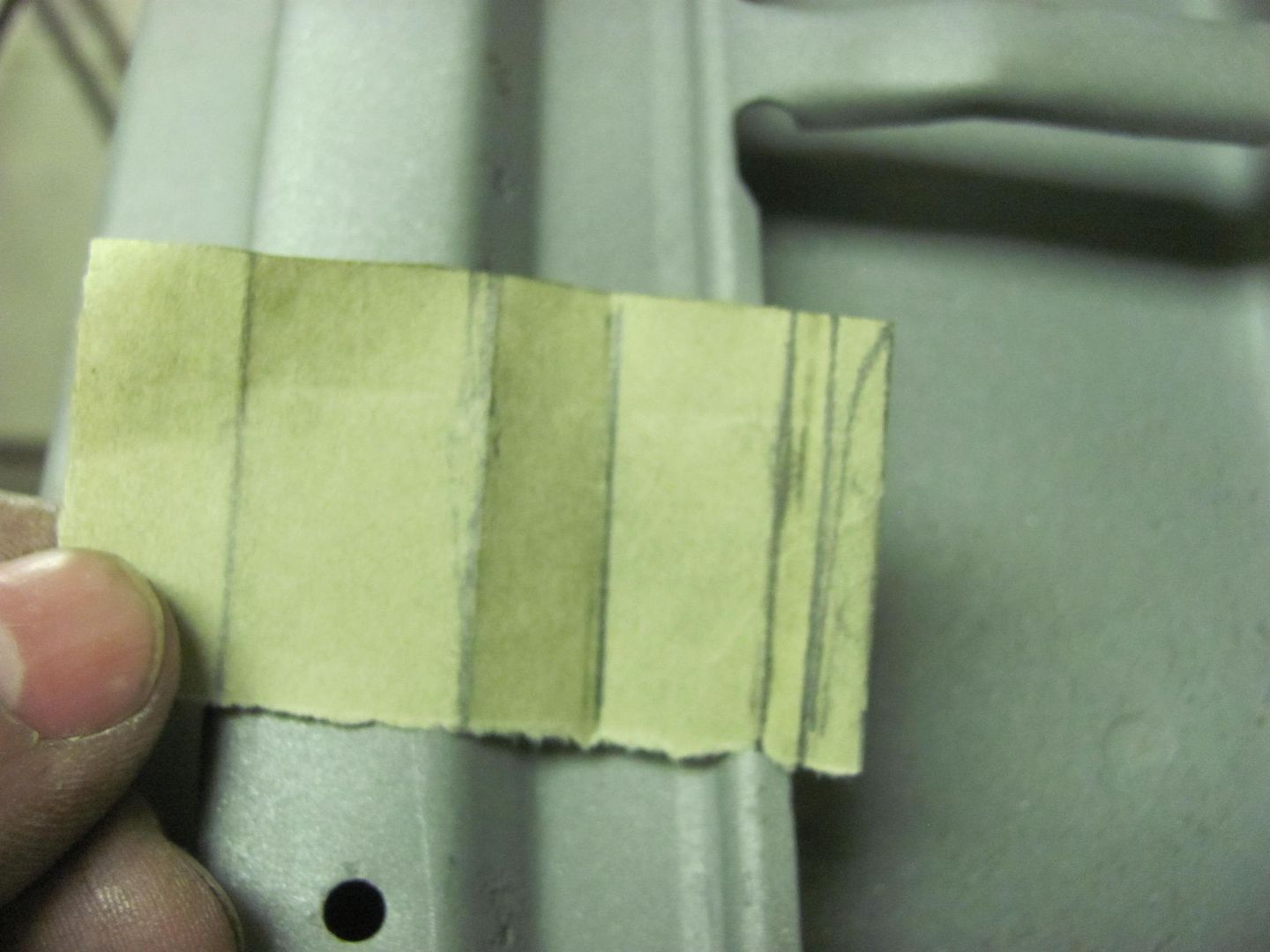

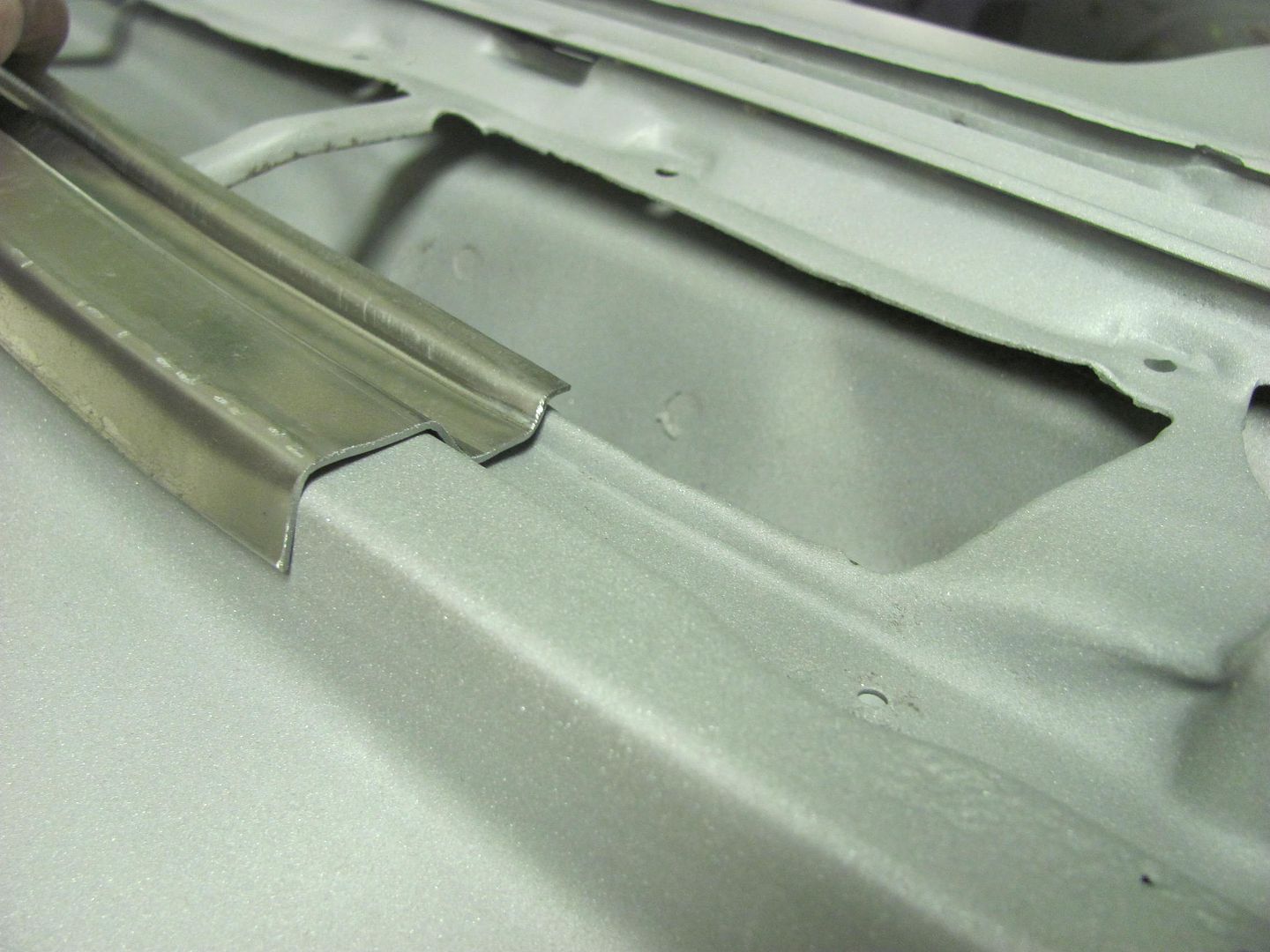

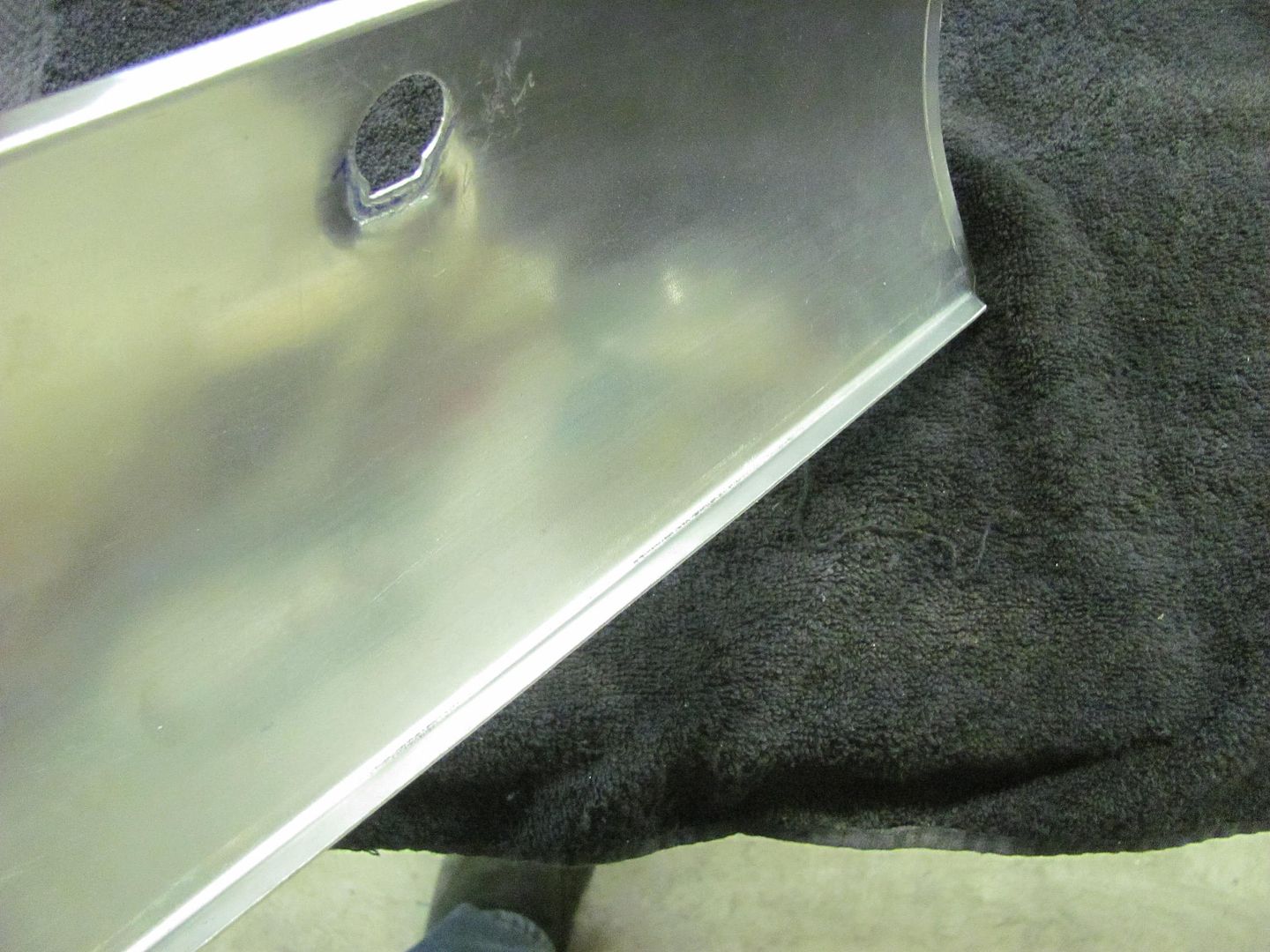

The bottom flange was measured, trimmed, and folded in the Diacro press brake

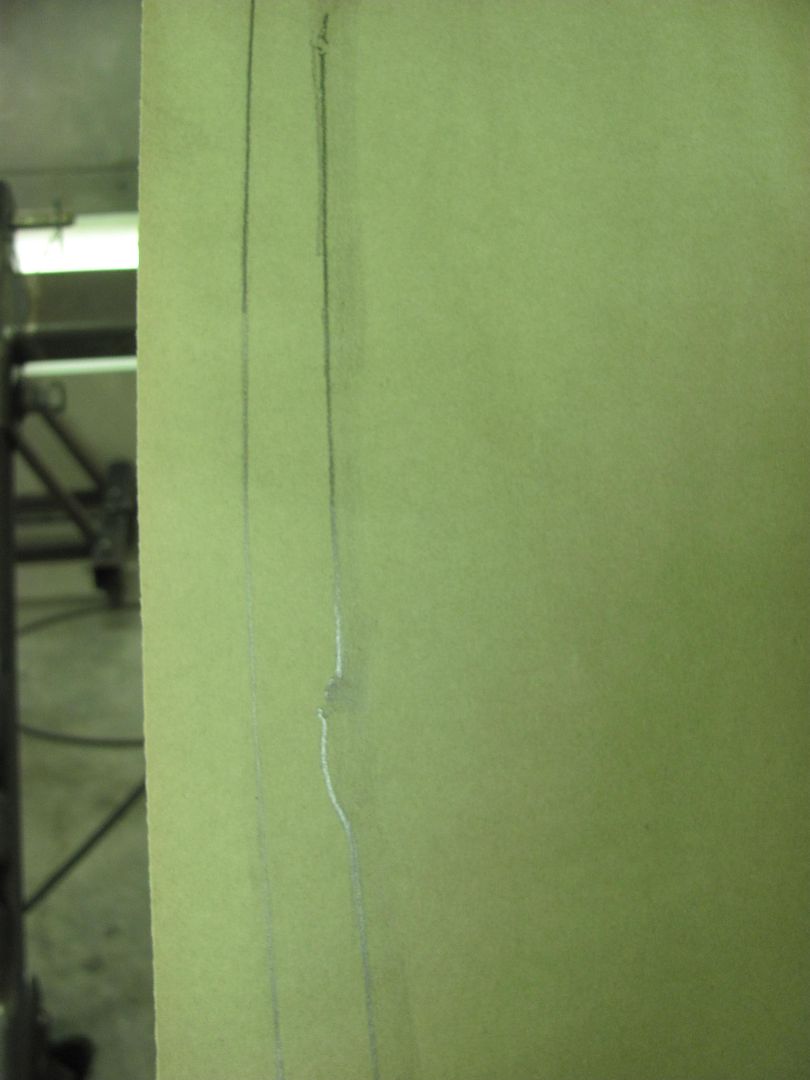

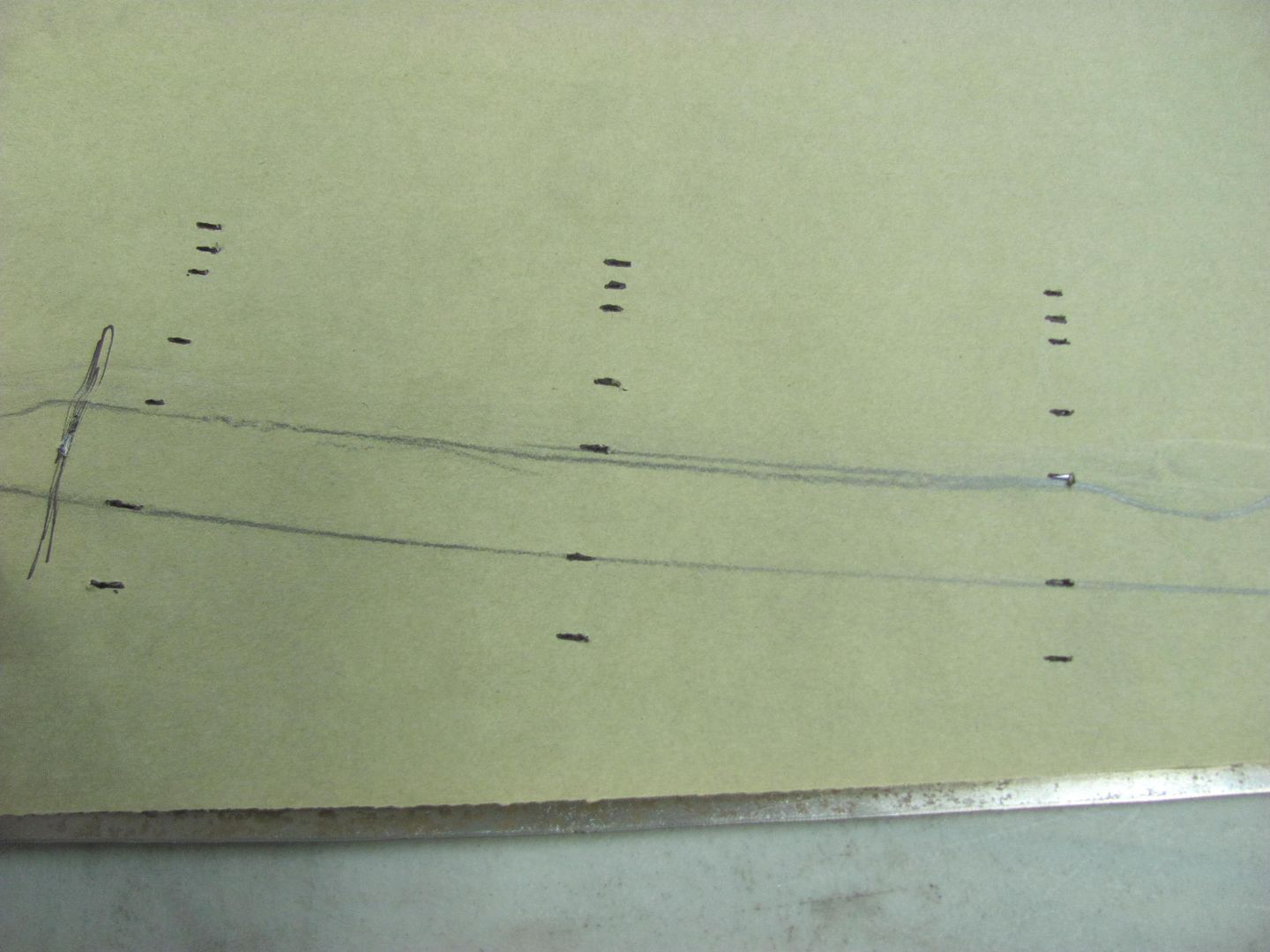

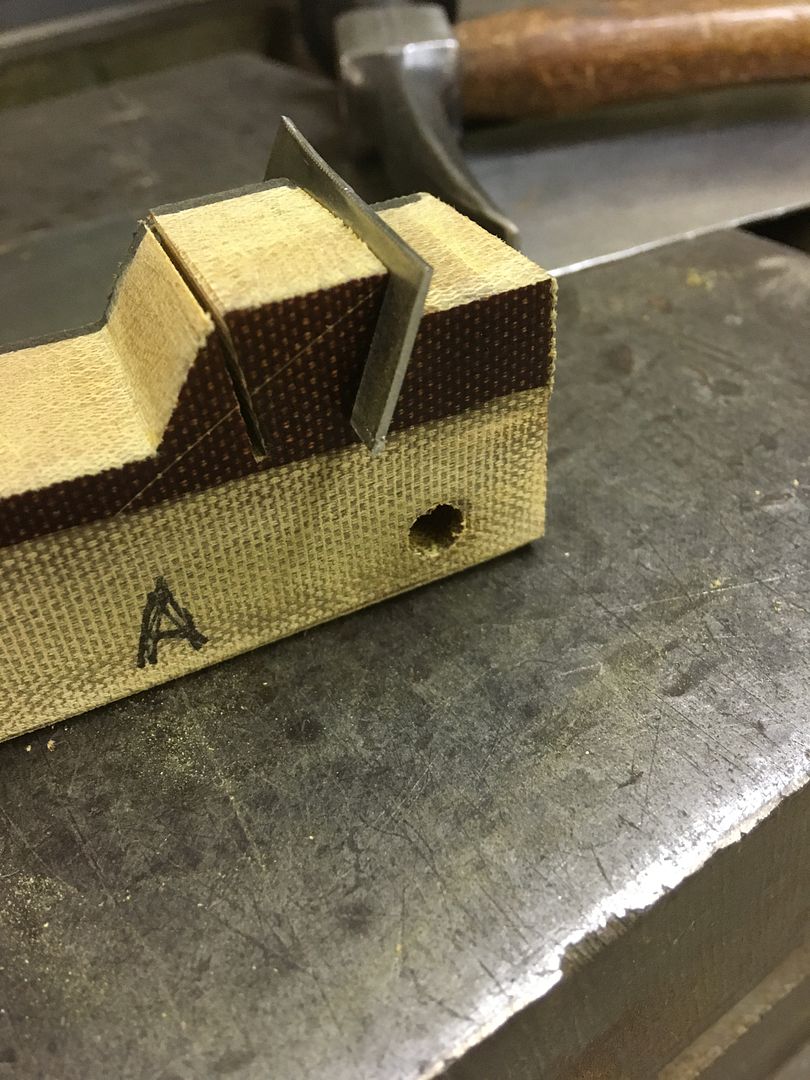

The side flanges were tipped slightly in the Bead Roller.. This also gives us a nice mark to show the fold line..

Touched up with the DA

With the three flanges folded to a 90, now we'll media blast and epoxy before assembling the two halves.

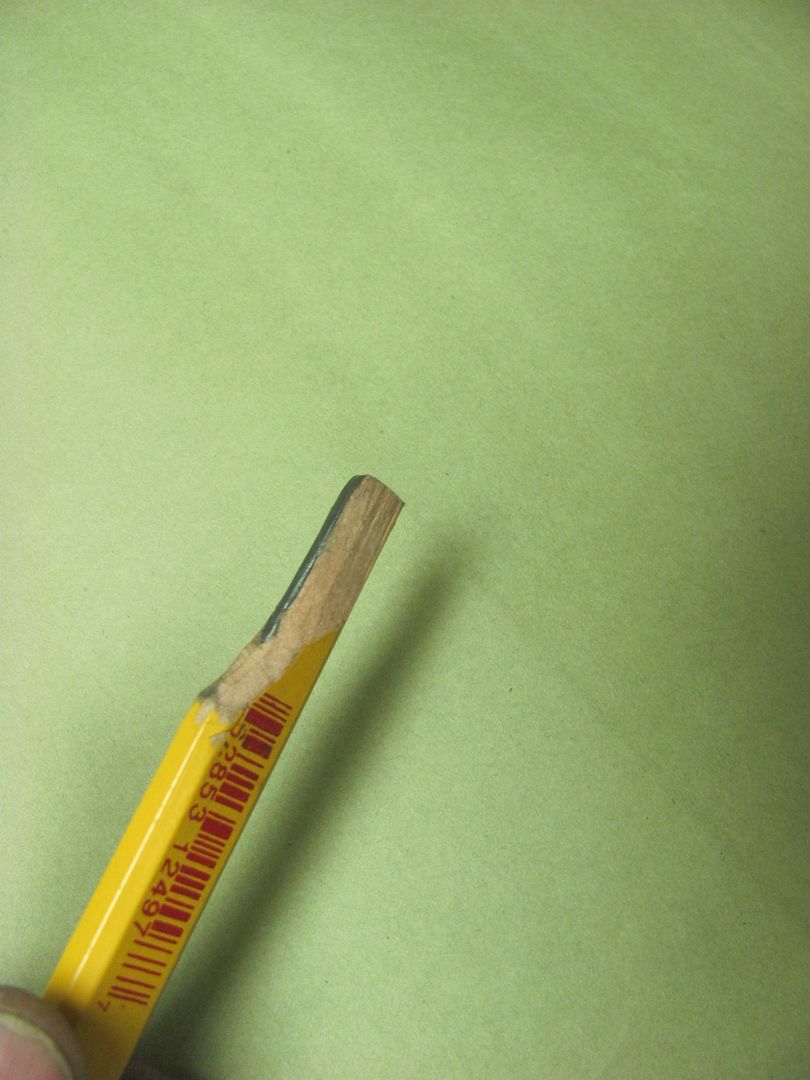

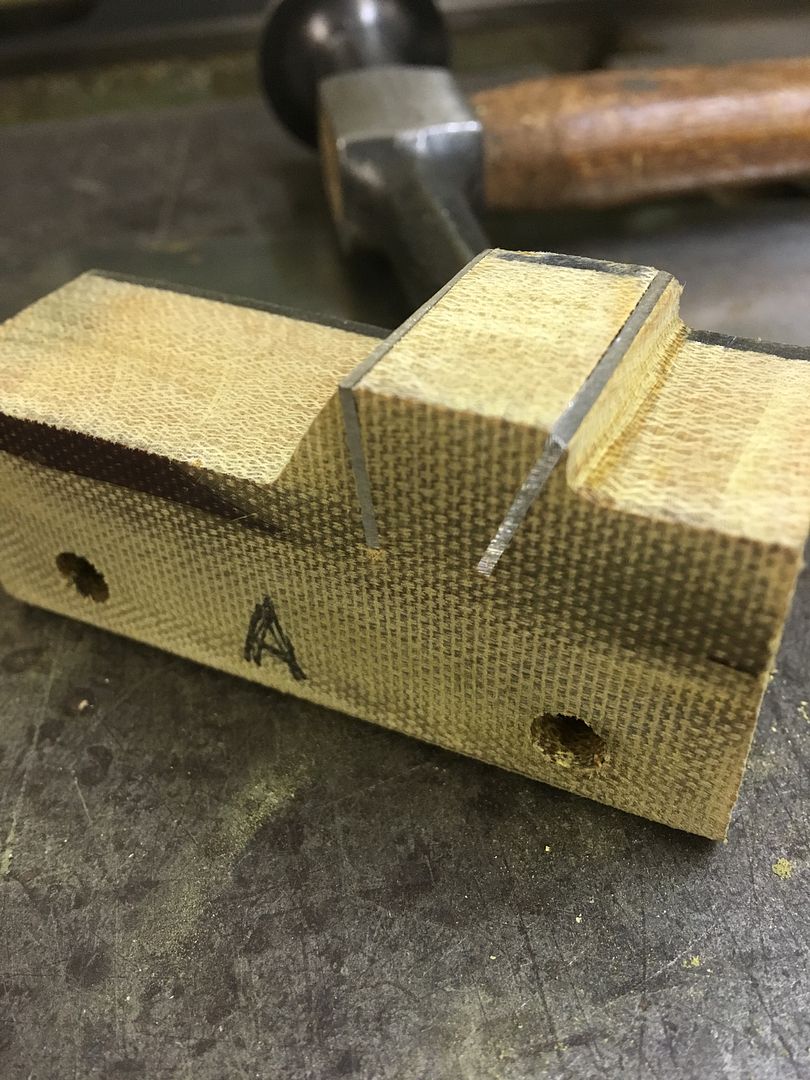

This shows the tipping tool used on the side flanges.

With lock cylinder. Looks almost factory...

Reply With Quote

Reply With Quote