Tonight we worked on getting the front fenders ready for epoxy primer, just a few more items to cross off the list. An earlier repair to resolve some rust on the top of the fenders.........

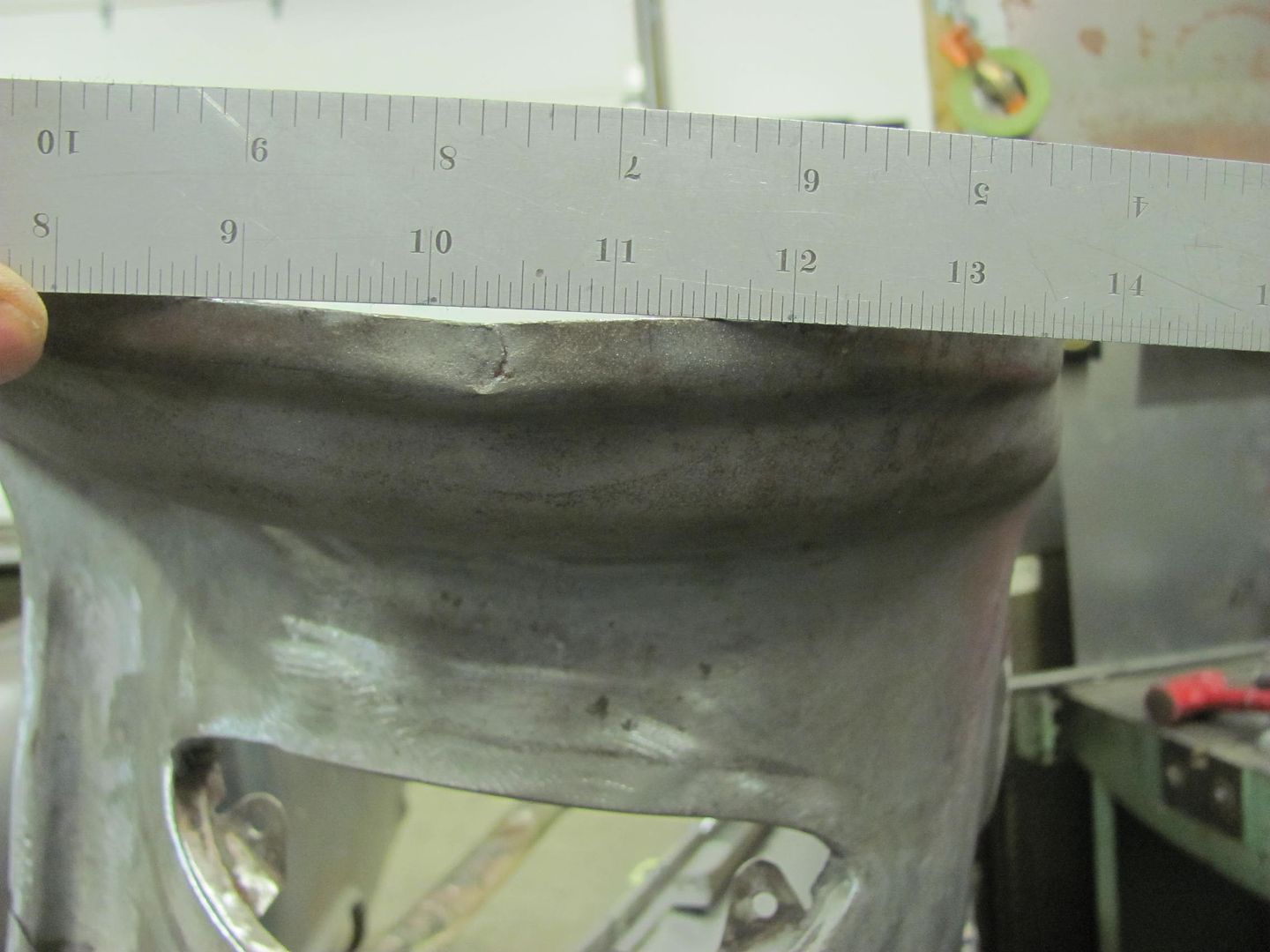

.........when checking the gap to the hood recently we noticed it was slightly wide at these spots where the weld had pulled. Shown here with the straight edge....

Time to make a tool that will reach between the inner fender brace for a bit of bumping...

The shortened hammer comes in handy again...

A few good raps along the area brought it out nicely.

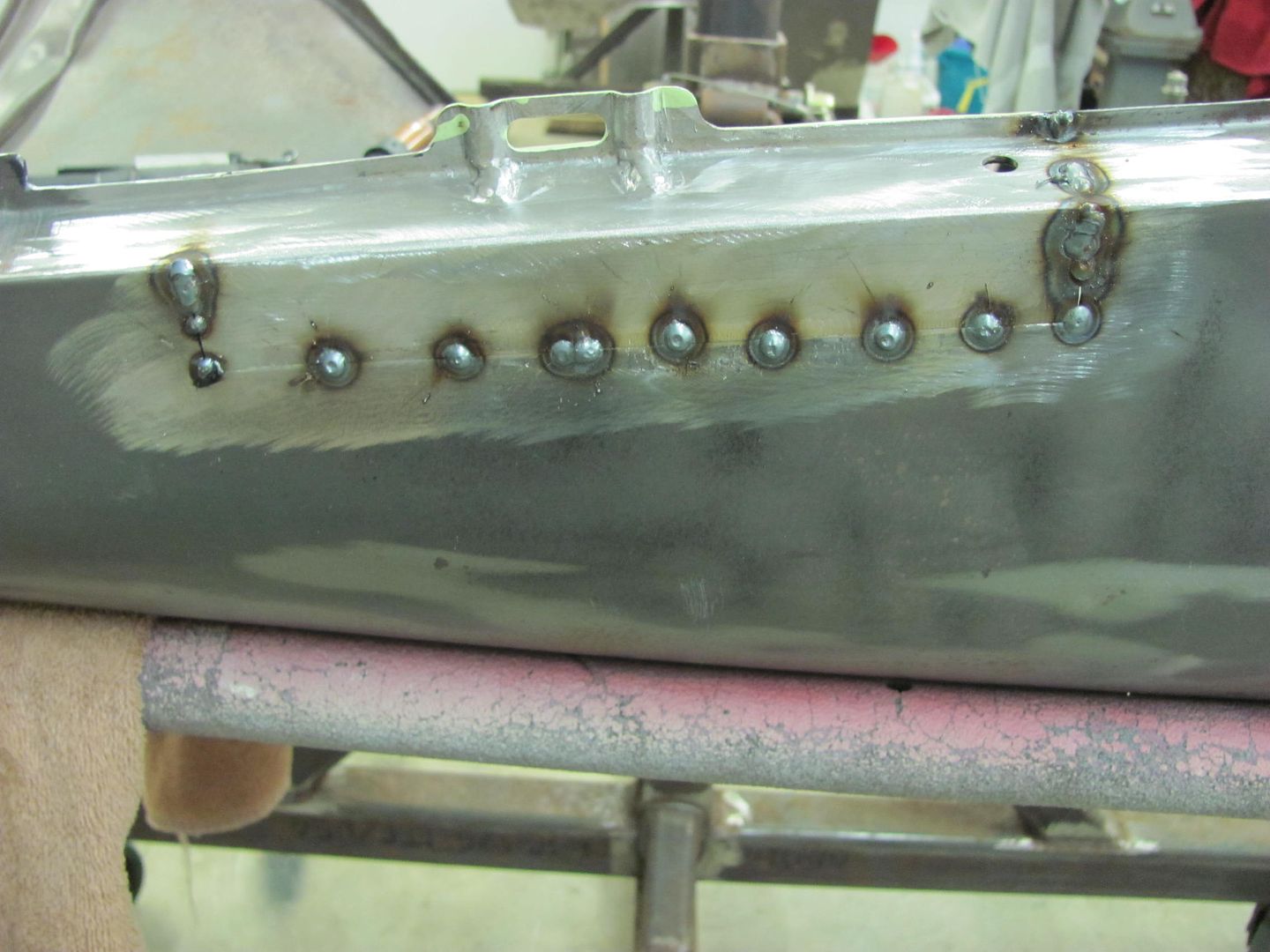

Next, we have some early model fender emblems to install on the front fenders, so we needed to fill the old holes...

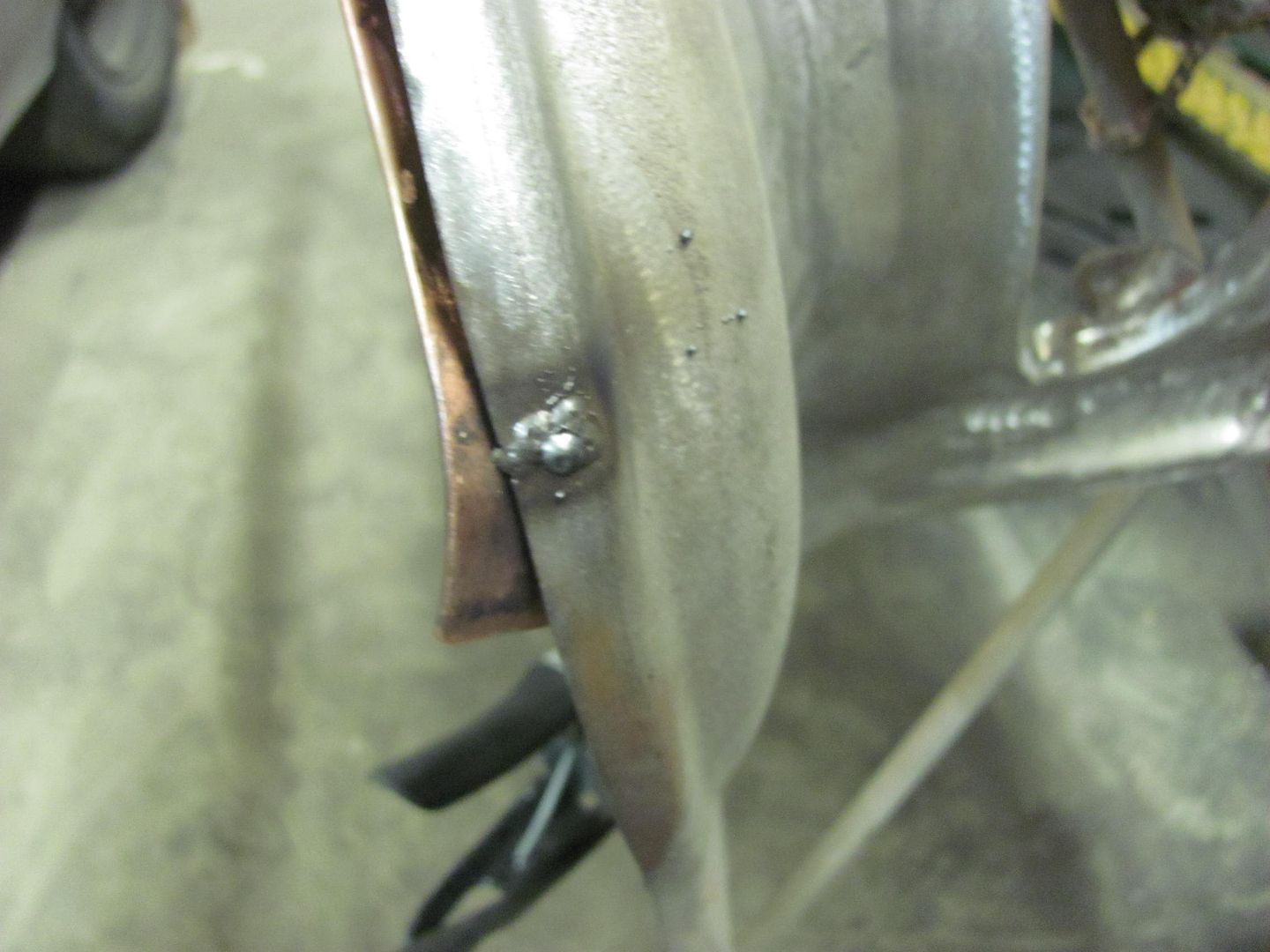

Three separate quick zaps were used (about a minute in between) to minimize the heat introduced into the panel for filling the slotted holes. Note minimal HAZ..

Holes laid out and drilled for the new emblem...

Other fender...

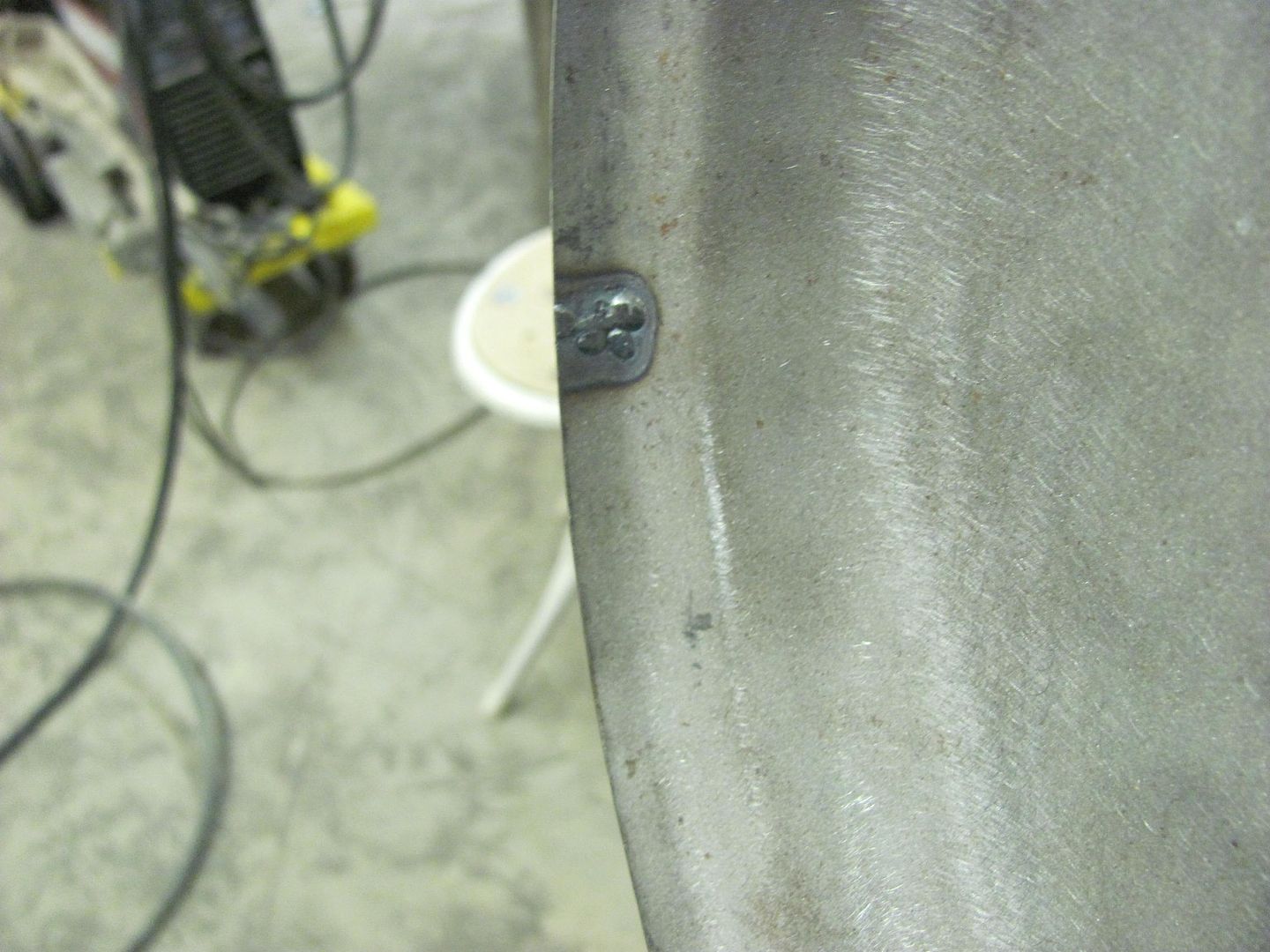

Note minimal weld bead height using EZ Grind..

Next, we had one more minor adjustment to do to the driver door lower corner. It was tweaked inward slightly and needed some adjustment. I recently noticed one of my hole punches was broken, and it looks like it will work for what we need, in conjunction with the vise grip dent puller...

Kyle started media blasting the inside of the driver's fender.... A bit of a squeeze in a 58" wide blast cabinet..

Rather tight to the door!

Until next time.....

Reply With Quote

Reply With Quote