Steering column one step closer to green paint...

and blocked to 500 grit...

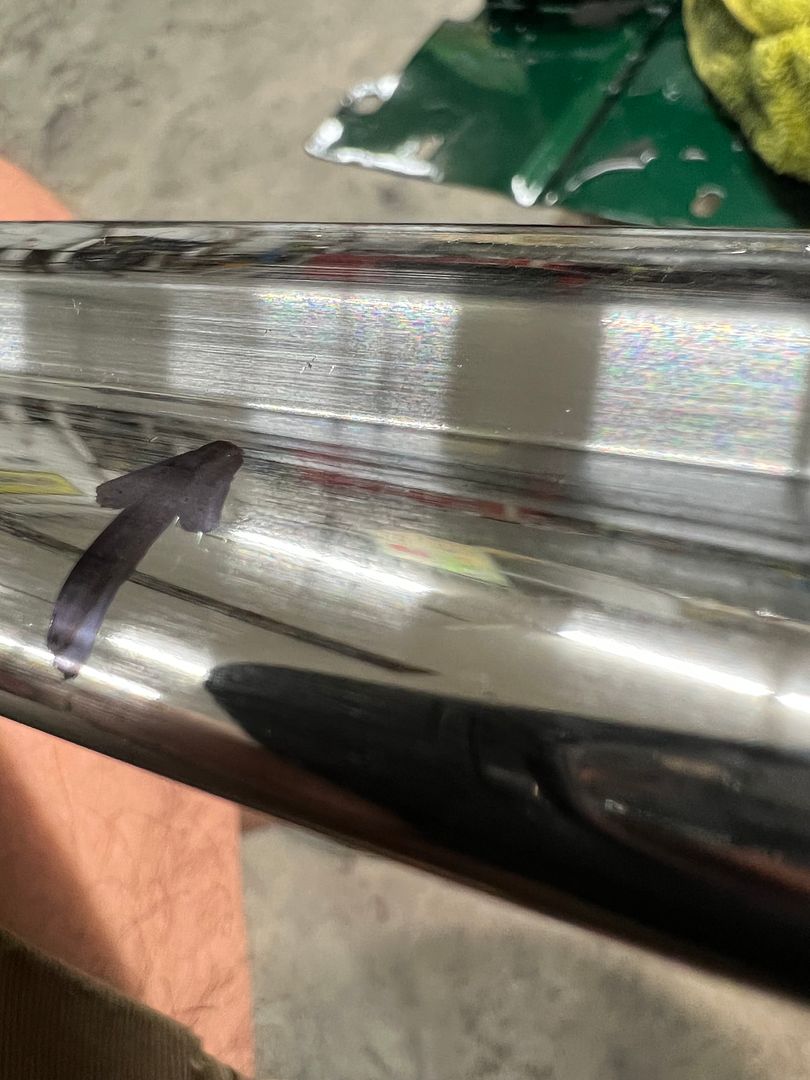

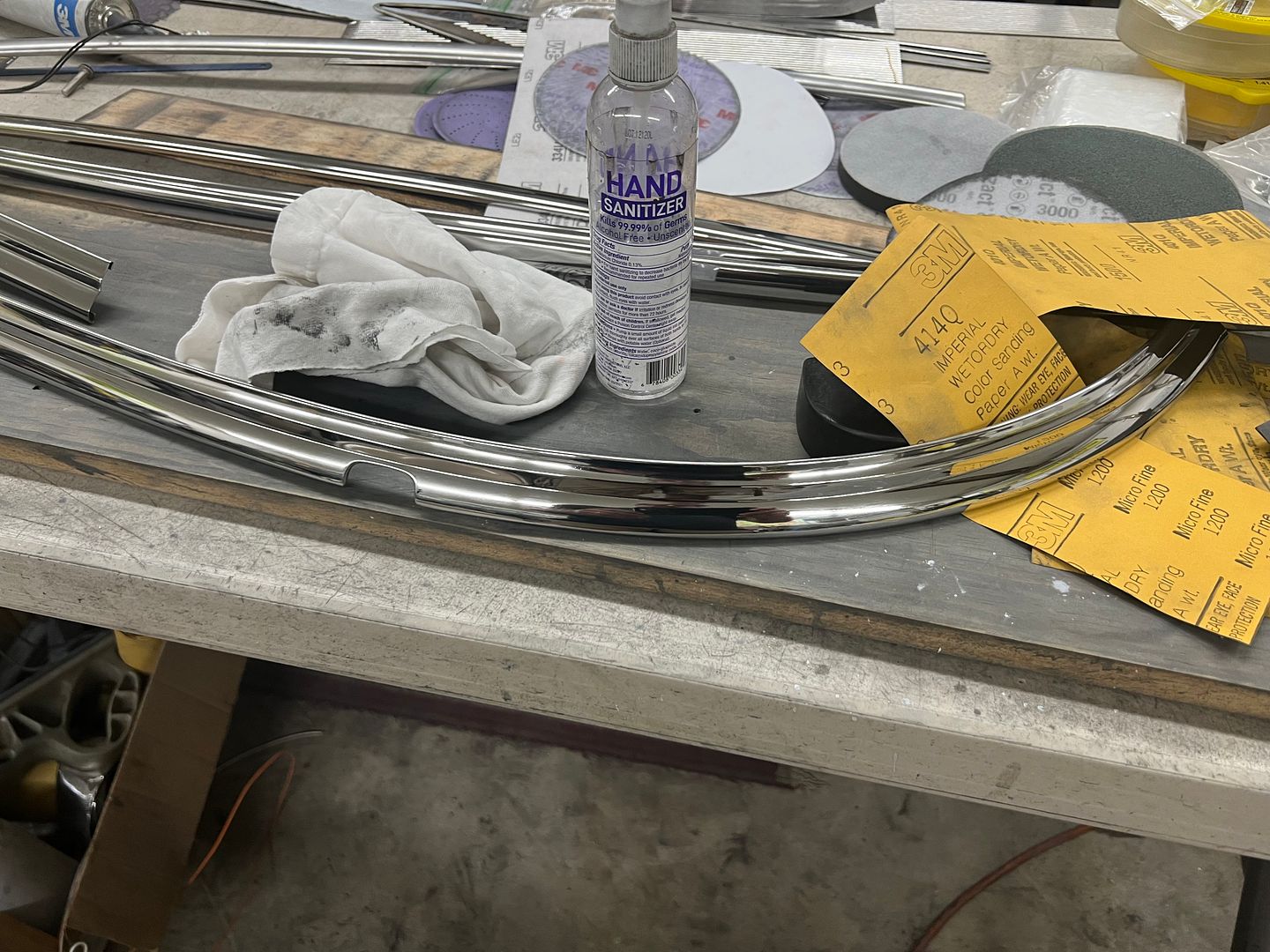

Working on removing dings and refining scratches on the windshield trim in prep for polishing. These pieces are less receptive to using the DA due to all the creases, so we've resorted to wet/dry paper up to 2500 and then polish.

Jared getting the hang of this stainless work....

For the other wagon, we went with a powder coat chrome finish to dress up that front dropped axle.

And this is the second round of three coats of epoxy and blocking. Think this will be the last round, and then on to some silver base and blue kandy..

Reply With Quote

Reply With Quote