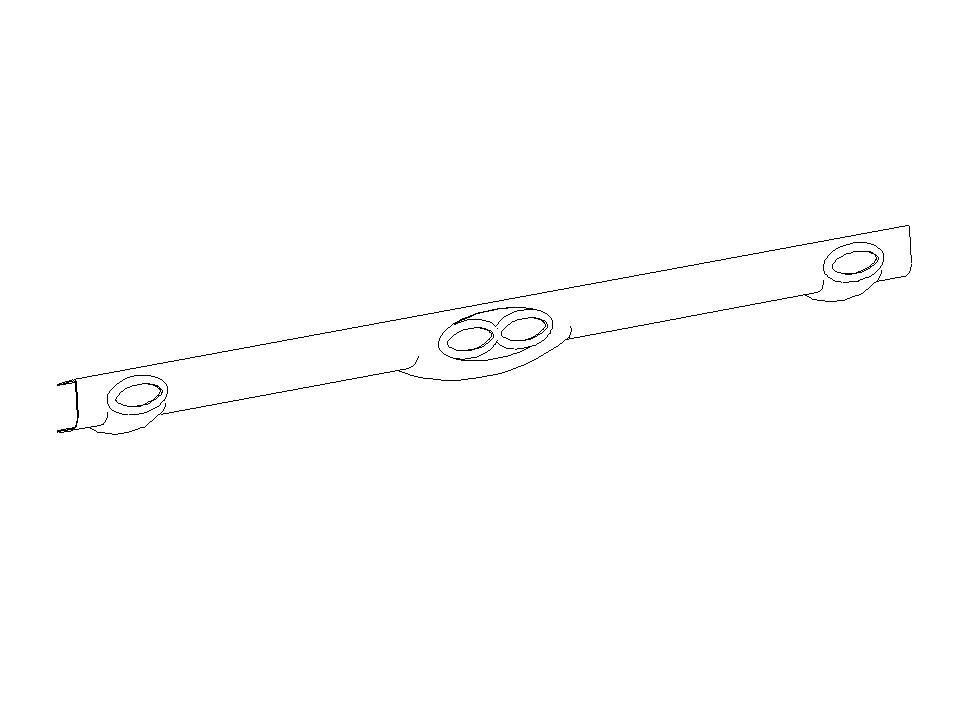

I have been working on the design of my dash valence, and this is what I've come up with so far. I think I'm going to put 4 oval A/C vents in it, and it's going to flow into the console, which will have a trim piece on the top of it. It's 3" wide at the outboard ends and 5 1/2" wide by the console.

The two side long sections will be made out of aluminum and there needs to be a 1 3/4" flange at the top and bottom. I'm trying to figure out the best way to fab this part. I think I need to bend the top flange on my brake and cut the shape on the bottom, then weld the entire bottom flange to it. Any other ideas how to make this? I think the bottom flange is too wide to try to bend over with a hammer form or a tipping wheel and hammer and dolly. Even the top flange will have to be cut a little and welded to shape it to the bottom of the dash, as it's not completely straight.

CCF05312015_00002.jpg

Reply With Quote

Reply With Quote