I think Laszlo and Nick had asked before about using a mag brake for heavier gauge in making brackets. I was working on some frame plates tonight and had some scraps left over so I bent a piece to see how well the Mag brake did. Here's the brake...

This is a bit proud for 12 ga so likely it is a thin version of some 11.

The section bent was about 6" across...

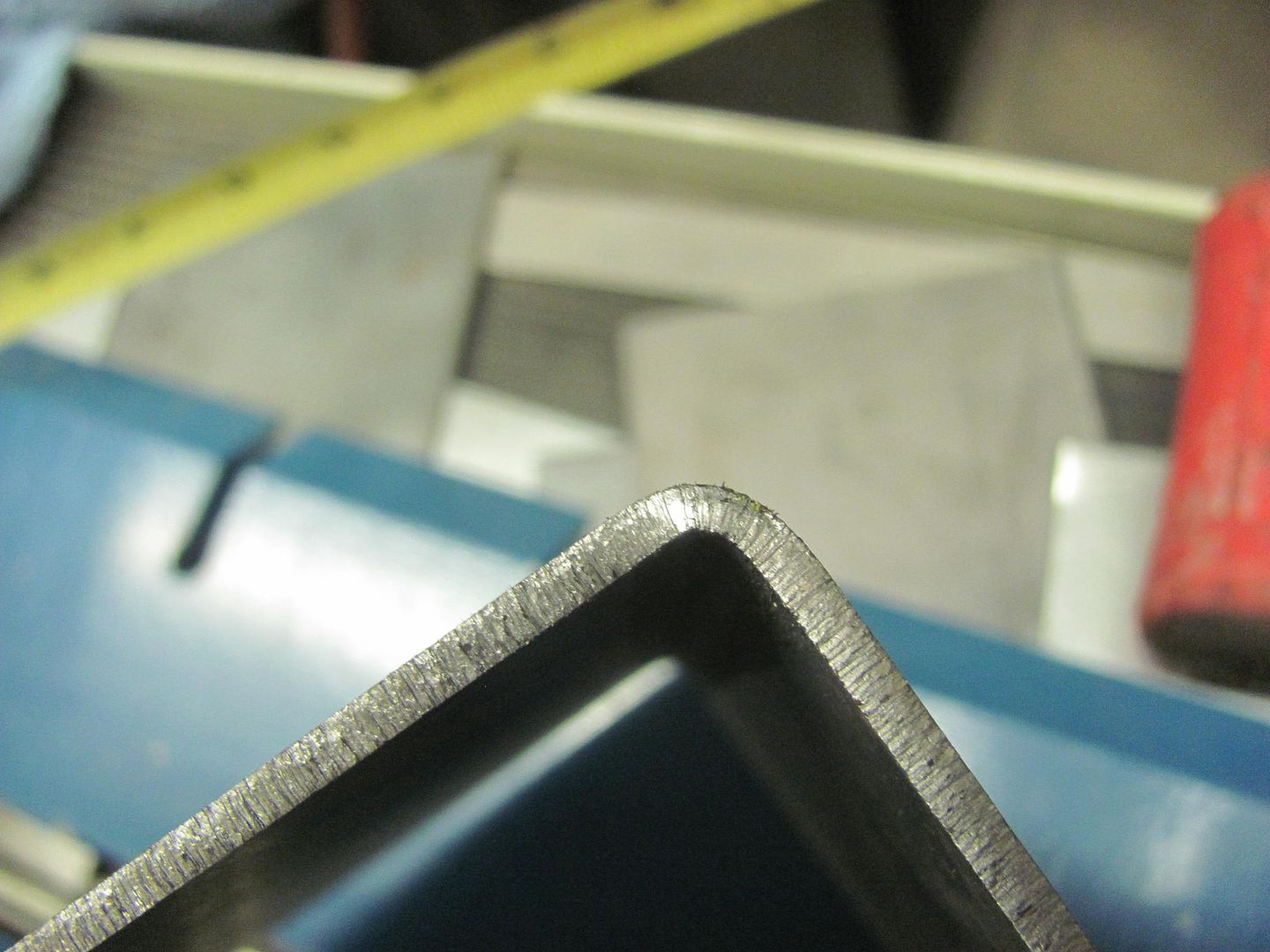

Where it wasn't a perfectly tight bend, I was rather impressed that the inside radius was only about 1/16"

Keep in mind whenever you get to the upper limits on a mag brake, additional "anvils", or whatever they're called, will help to give the magnet more to pull against so the work piece is less likely to pull upwards when bending..

So if that width and inside radius is OK with you, then the 4816 may work for you. In looking at an ad this morning for the Roper Whitney version of this brake, they advertise bending smaller widths up to 10 ga steel.

Reply With Quote

Reply With Quote