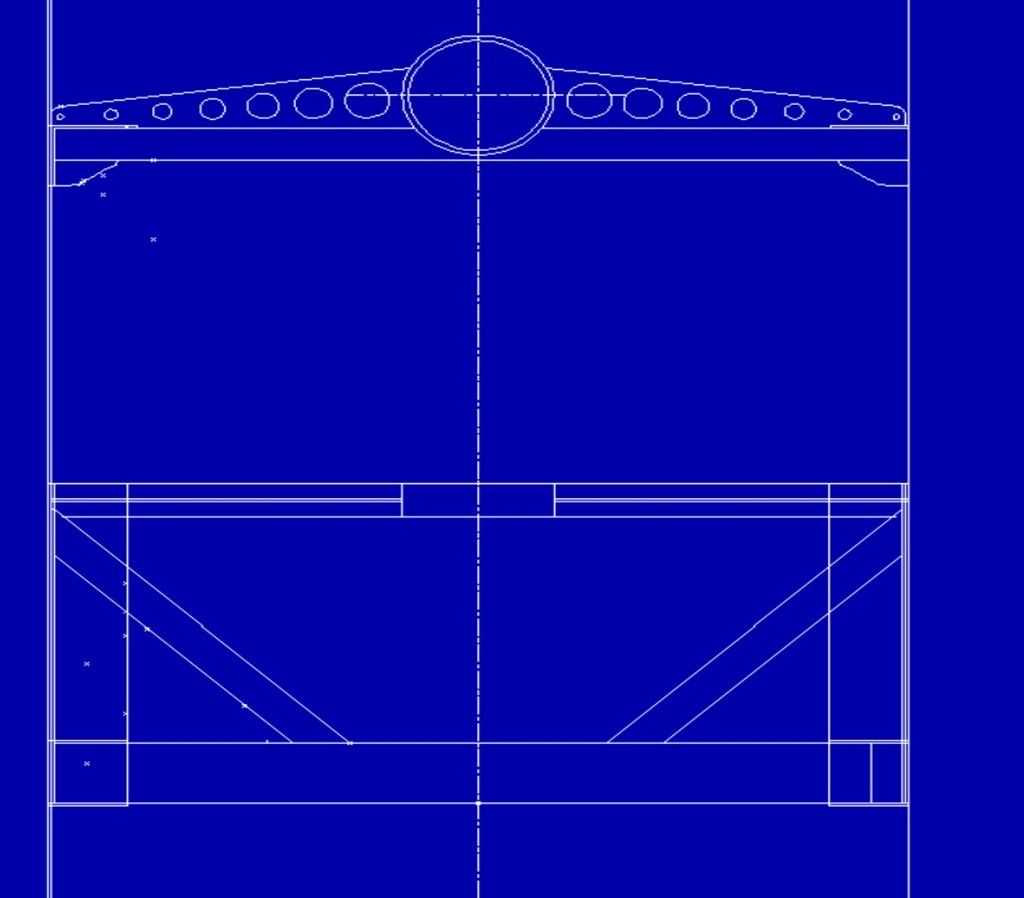

I have been looking at my chassis design before my nomad ships off to paint jail. I have posted a link to C'nuts site for discussion. I am considering adding a cross member fwd of the rearend as he has the AM version if you will. I currently have a set of brackets designed that hang the exhaust and also mount the e-brake cables. Looking at the sway bar design I have I am also seeing opportunity to incorporate an attachment for it directly to the new cross member everything seems to merge at that location directly behind the body mount. I'm also thinking it is a good place to add support across the frame at the fwd spring mounts on my stock frame. Anyhow a few questions.

1. How much droop do you design in the loop below the drive shaft for clearance?

2. How much ground clearance is at the loop?

3. I assume the rear has to be dropped to pull a drive shaft in the AM design?

If so I would like to design a top loop in mine like fatman frame and have the lower center section un bolt so I could drop it to replace drive shaft.

I have also included a few pictures of my center cross member I pretty much got it figured out. I'm going to extend the 3x3 angle I have attached to the drive shaft loop tubing and tie it to trans cross members along the frame rails and remove my current angles that are supporting the trans cross member this will make it much more rigid. The center section will be bolted in along the rail 16 inches and can be dropped to replace a trans.

Thanks in advance Rocky

http://www.classicedgedesigns.com/projects.html

Reply With Quote

Reply With Quote