Greetings folks,

This is a cross-post from that "other" forum -- ChevyNut enlightened me a while back that there was also another community, so figured I'd share my build progress here as well. Plus, it gives ChevyNut a chance to see what all my pestering him has resulted in.

The Story

Around the time I was 14 in '97, my father invited me along to check out a '55 Bel-Air HT a coworker had mentioned. This was rather exciting for me as I always loved the shoebox Chevy's and such things were usually reserved for my older brother. We drove out to the middle of nowhere in the U.P. (that's upper Michigan, for you uninitiated folk) to check it out. Unfortunately, there wasn't much left. The car had been converted to a stock car some time before and most of what remained had been scavenged or hacked apart considerably. Feeling a bit disappointed, we started to leave when I noticed the rear fin of a '57 stick out around the side of a building. My curiosity got the better of me and I walked over to check it out.

What sat before me was a rather complete, '57 210 2-door sedan, with a plethora of extra side moldings, bumpers, carpet, and other parts cluttering up the interior area. The car was sitting in primer and looked decent to my rather inexperienced 14 year old mind.

I had to have it.

After about 30 minutes of begging and pleading, my father managed to negotiate an amicable sale price of $1,200 and off we went with our new toy.

Unfortunately, in a family of 7 living in rural Michigan, we didn't have a whole lot of money to toss toward the old girl, so she sat in the garage waiting for a number of years. However, it became kind of a bonding point for my father and I, as we would often find ourselves in the garage seeing if we could get it to start again or debating over what color it should. However, that didn't stop him from trying to abandon the project at times. There were multiple occasions where he expected we would never get to it and tried to sell it. However, I would intercept all of the interested phone calls and promptly inform them it was SOLD and to bugger off. I wasn't about to let it get away from me! It was one of the few things we had that would bring us together, as we often struggled to find common ground -- I was a nerdy, brain of a kid obsessed with reading encyclopedias, physics, and so forth, and he was a mechanic interested in how much compression he could squeak out of his 454...

This is what the car looked like a few years after we had picked it up, we really didn't do much at all other than get it running and drive it around the yard, so this is a good reflection of what I convinced him to buy for me.

Fate was against me, however, and he was killed in a work accident in early 2000. To cope, I fled the area and the car to get away from the constant reminders that he was gone. I returned a little bit later, determined to finish what we had started, but I was rather lost as I was depending upon his experience to help me through. But, I was determined to figure it out. So, I slowly began stripping the car and prepping to pull the frame out from below. That's when I began to notice that the body wasn't quite as straight as I remembered it being at 14...

But, I trucked on anyway, and got it ready to pull from the frame.

However, fate was once again not on my side and my brother blew the engine in his truck, requiring me to put the '57 on hold temporarily... Unfortunately, by the time I regained access to the garage I was embroiled in a legal battle over who was going to take ownership of the garage and the project sat for years once more untouched, until I lost the garage in its entirety. Feeling extremely depressed, I was forced to abandon the car under a lean-to sitting in a field, fearing I may never get to it.

Here it is being loaded up to be moved to the field, which I thought might very well be the last time I got to see it...

However, a few years later, I managed to buy a house with a garage (albeit, much smaller) for the sole purpose of finally getting my '57 built.

On my wedding day, my sister and her husband brought the car down and dropped it off. Here it is in its new home, next to my '94 Mazda RX-7.

So, I'm determined to get this thing done and finished before tragedy befalls me once more.

So, I've set out a basic list of goals:

- Stock, Bel-Air Exterior, painted Montego Blue (I keep changing my mind here....)

- Stock appearance interior -- ie, no "modern" looking seats UPDATE: went with '63 Impala SS buckets

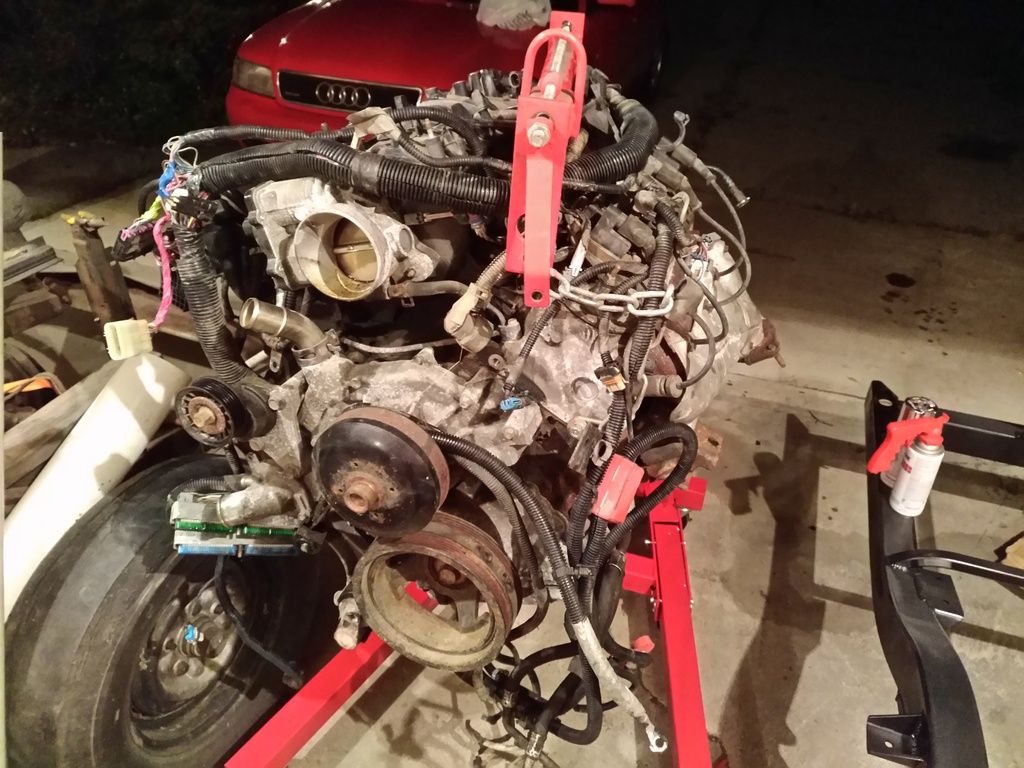

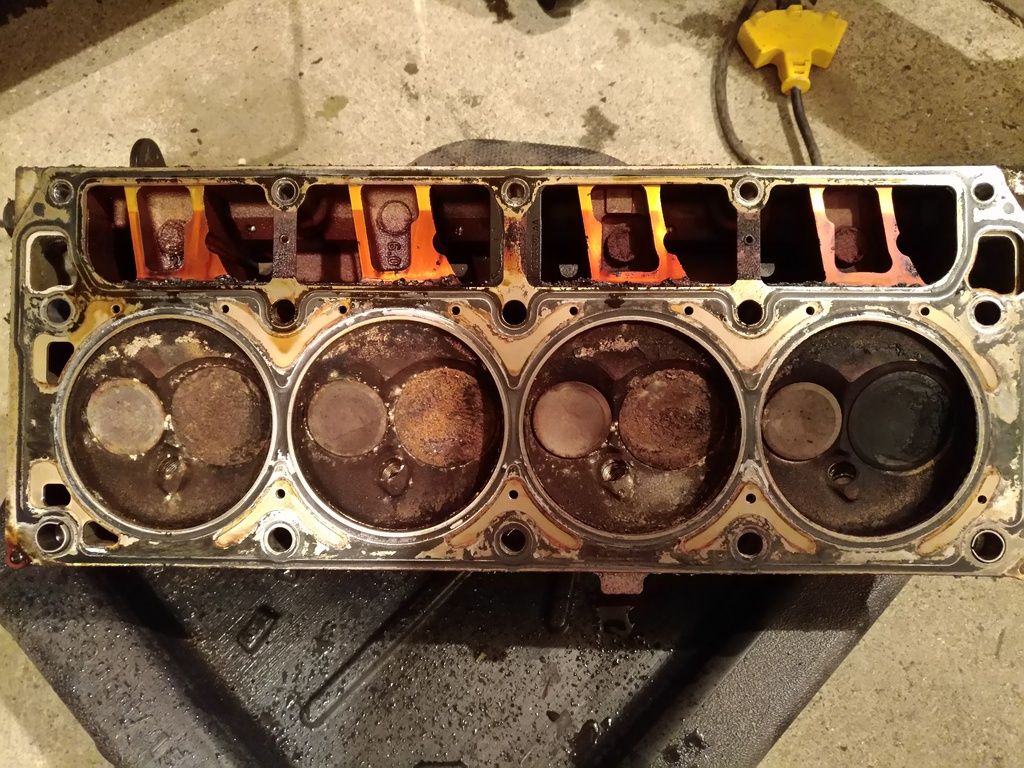

- LQ4 w/T56 maintaining EFI -- debating on stroking to 408 or going twin-turbo (I have a tendency to turbo everything I touch)

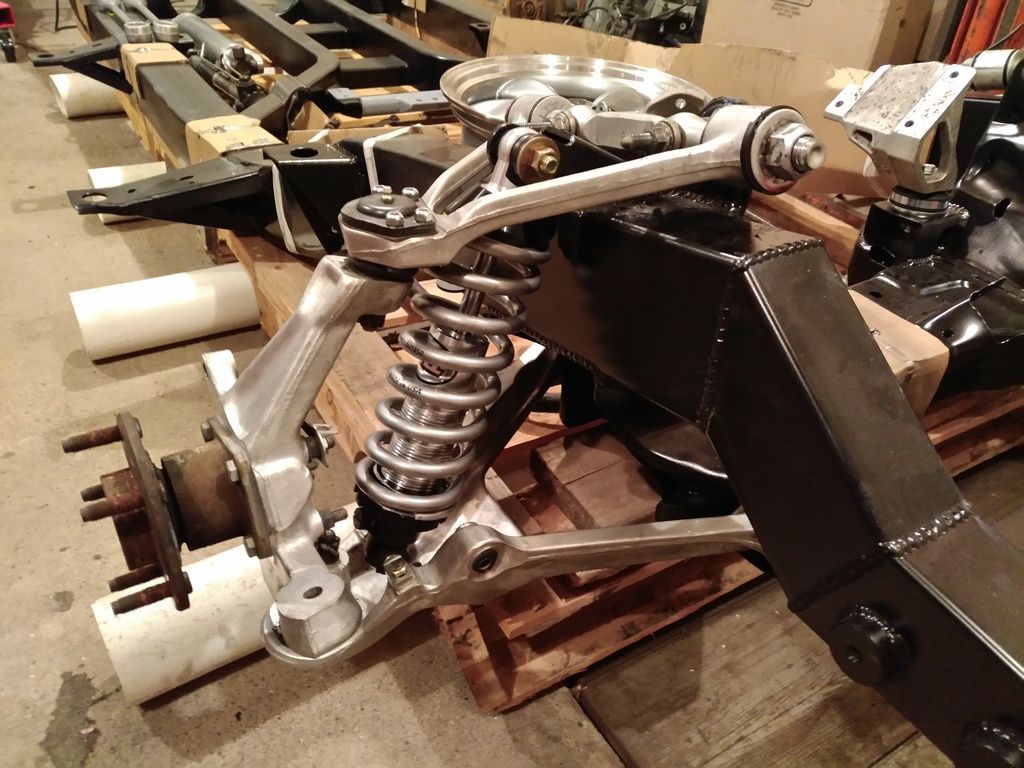

- C4 Suspension (Thanks ChevyNut!

)

- Mini-Tubs

I've employed the expertise of CLASSIC EDGE DESIGNS (www.classicedgedesigns.com) to put together the frame. Laszlo has been incredibly patient with me and an absolute joy to work with as he constantly endures my idiocy.

With the frame underway, I set off to analyze my situation and determine what all I'm going to need. I didn't quite expect the can of worms I encountered.

The floor felt plenty solid years ago with the carpet in place. However, after removing the carpet it became obvious that the prior owners had installed a number of patches -- poorly. They simply installed panels over the existing floor and left what remained to rot away.

A full floor will be necessary. The toe boards are solid all the way to the original seam, so I'm happy I won't have to do any fabrication or patching there.

The trunk had a rather well done patch in place, but again, it simply hid more bad news. The entire rear drip section, along with the trunk brace and body mounts are completely gone. Additionally, rust is lurking all along the inner wheel quarter panels, on both the wheel wells and the quarters...

Additionally, when I began investigating the rather poor quarter panel surfaces, i discovered the previous owner installed new quarter skins... on-top of the original quarters...

I'm waiting for the new frame before I begin any major body surgery, as I'm unsure of how straight and true the current frame is. In the meantime, I've been torn over how I should go about repairing this. Both quarters are almost entirely unsalvageable, so I'll need to replace both -- I'm torn on if I should patch in the HT panels everyone seems to be using or if I should install the factory sedan panels that are available now. Additionally, my inner quarters are in extremely poor shape. Where they attach to the inner rockers is rusted out, the drain areas are rusted, the wheel wells are essentially falling out, and the rear panels at the trunk are almost completely gone. I can't decide if I should patch all of this or replace the entire inner quarter with the pre-tubbed ones, since I plan on going with the pre-tubbed floor anyway. Finding experience with the fitment and quality on those is rather difficult, so I may have to play a guinea pig.

Reply With Quote

Reply With Quote