Had some visitors at the shop a few weeks ago, John Glenn and his father (from Anderson Auto Glass, Anderson SC) came up so we could use the truck floor dies to modify the ribs on a 2009 Ford replacement floor for use in a 1966 Ford they are restoring. The new floor has flat area provisions for a fifth wheel bracket and the original floor in a 1966 has full length ribs front to rear. We needed to modify the flat areas to provide these full length ribs. James McKenzie also stopped by to help in the activites.

QUOTE (John Glenn) I didn't go into much detail about this earlier, but the F250 bed floor had four flat areas for a fifth wheel hitch that looked really out of place for use in a '66 F100. I contacted Robert (MP&C) about having him make dies for his Lennox to reshape those spots into continuous ribs to look more like the original bed floor. I sent a sample so he could make dies a while back, and yesterday our schedules finally aligned so we could work on the bed floor.

We started by gas welding plugs in the four holes that won't be used on the F100. I didn't want to weld those with a MIG at our shop since the weld would be more brittle and would probably crack during the reshaping process. Gas welds are much softer and more workable.

The welds were smoothed down and the flat areas were pre-stretched in the english wheel with a bit of guesswork as to how much we should pre-stretch.

Then into the Lennox to add the ribs. This was done gradually in multiple passes, adjusting the depth of the dies after each pass.

Slightly reworking the dies to gain more rib height.

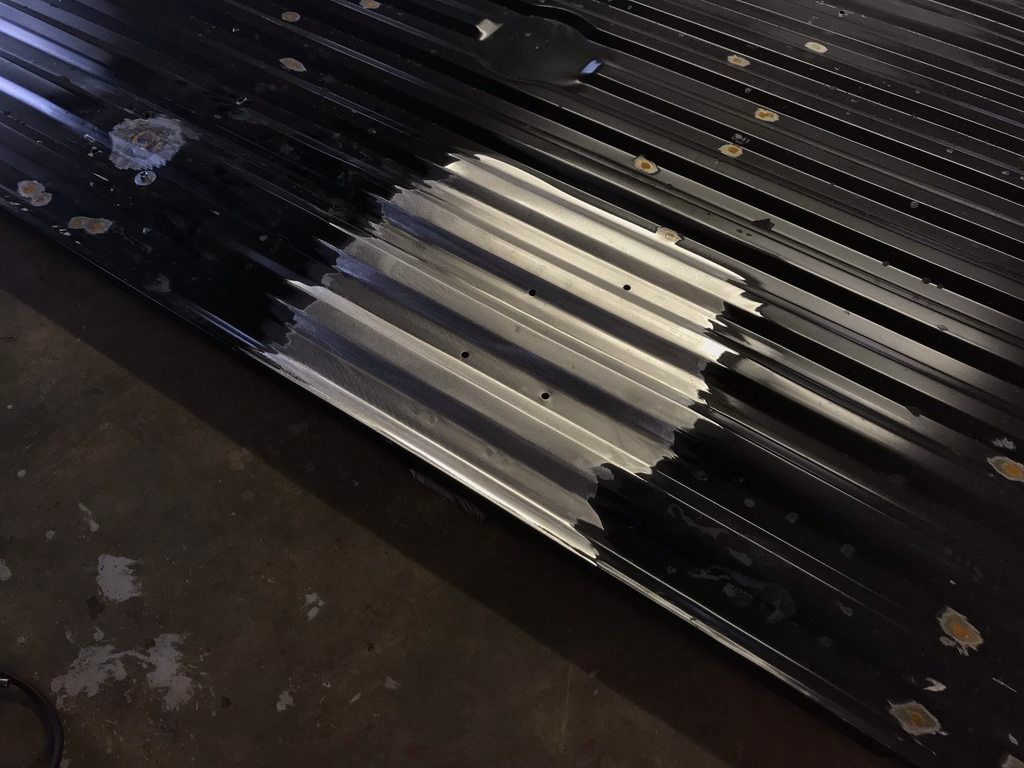

Finished ribs. These are hard to photograph so I stripped an area with the two new ribs in the center of the outer original ribs to show the matching profile.

James (duallyjams) dropped in to hang out for the day, it's always good seeing him! He was a big help and also shot vids of us working.

Time lapse:

http://www.youtube.com/watch?v=5ofQasdZDo8

Reply With Quote

Reply With Quote