Got your engine pulled or front end off the car? Another area to check while you're there is the cowl vent area, especially to the outside of the front body mount.

The cowl vent/kick panel area are often overlooked when performing rust repair, but due to their design are prone to rust damage from the inside out. The inner cowl area on the 55 and 56 provides fresh air to the kick panel vents, which also makes use of an internal gutter system in an attempt to keep your feet dry if the vents were to be open during a rain storm. Unfortunately this internal gutter normally fills with leaves and other debris, thus retaining water over the years and eventually causing rust. Telltale signs will be small circular spots of rust, and you can check if they are growing into pinholes by using an ice pick:

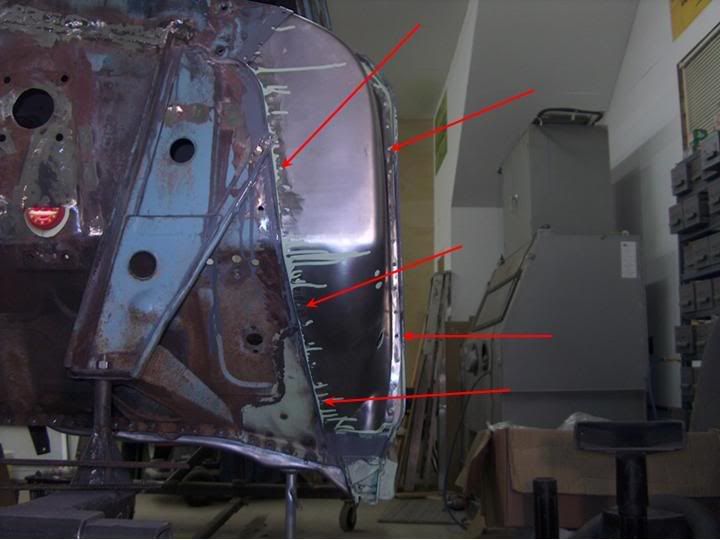

If removing the complete cowl for replacement, there are spot welds around the perimeter of the cowl that hold it onto the adjacent panels. If you are removing the cowl and replacing it with a new one, I would remove the spot welds shown in these areas (red arrows) using a 3" cutoff wheel to grind down to the second layer, so you won't go thru the second layer like you may if using a drill bit. On the outer section, the spot welds are recessed behind the A pillar a bit, so use a fresh cutoff wheel here, and when they just won't reach anymore, continue to use it on the inner section where it is more readily accessible. Or for those that have better luck using a spot weld cutter than I do, they may be used here to remove all the spot welds instead of the cut off wheel. Be sure to use extreme caution not to cut into the second layer, or you may be spending time repairing that before the cowl can go on. On the top section, (second picture down) the cowl has a flange that goes under the upper cowl area, so these spot welds can be simply drilled out with a drill bit to the size of your plug welds, as the new panel will tuck behind. The area pointed out with the green arrow has a flange that tucks up behind pretty far, and is the hardest part to get out, so try to leave this for last when prying it out. It will also give you the most fits putting the new one in, but it will go.

As the front of the cowl is cut open, we can see the problem area and some of the debris that caused the rust:

Now, while you're in here (if you need to be) there are plates covering the hinge pockets which hold the floating nut plates for the hinges. The upper ones will likely be fine, but the lower ones may have rust issues as well.

Hard to see from the mud-rust-scale, but there are pin holes through the cover plate on the bottom:

And behind the cover plate, more rust:

This is the replacement of the pocket that holds the inner hinge nut plate. This can be formed using a 3 x 3 square steel tubing as a female die, and a 2 x 2 square steel tubing as a punch. (leftover parts from building your own rotisserie) A relief is cut out of one side of the 3 x 3 “die” to better form a 3 sided pocket. Apply heat and dead blow hammer as needed:

Welded in, and drain hole formed:

The driver’s side was even worse as it was plagued with various pin holes around the vent area, so with either side, don’t be surprised if you end up with a hole like this to start:

Replacement laid out:

Bent up and test fitted:

Kick panel vent clamped for welding (area behind vent is welded in separately, allows you to replace kick panel vent in one piece):

Installed:

Next, to form the rest of the internal parts. Here's what was left of the retainer plate:

We'll need another punch and die:

Two holes joined together with a dremel or drum sander (or die grinder if that's what you have). Scribed lines from the originals keep the reliefs "keyed" correctly

Two pieces of round rod welded to the rectangular "handle"

This merely provides clearance for the bolts coming through the nut plate. Again, apply heat and dead blow as before:

.....and trimmed as per the original:

And next, the fab process for the internal gutter.

removed gutter:

Cut out:

Bent up:

Trimmed and fitted:

Welded up, welds dressed:

Comparison:

All parts welded in place: (the nut plate is then dropped in the pocket from inside the hinge hole)

And then all covered up for no one to see:

Reply With Quote

Reply With Quote