I am often in need of bending a short step in sheetmetal, something like a 1/8" to 1/4" step. I'm talking about a "Z" with a short step in it. How do you do that on a regular brake? I don't really see how you can even do it on a press-brake since the lower die is wider than the step. I see parts made like this all the time, but don't understand how they do it.

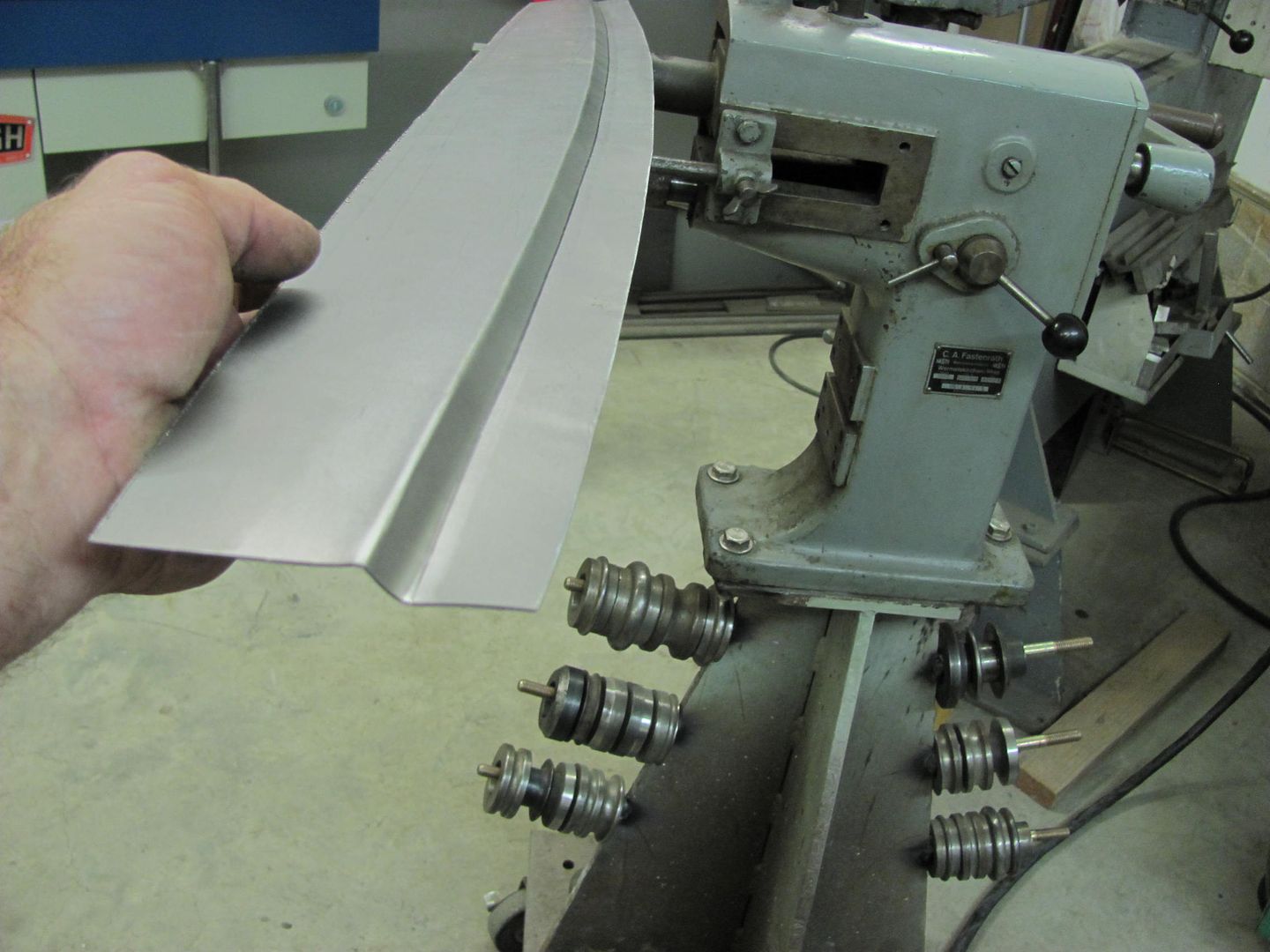

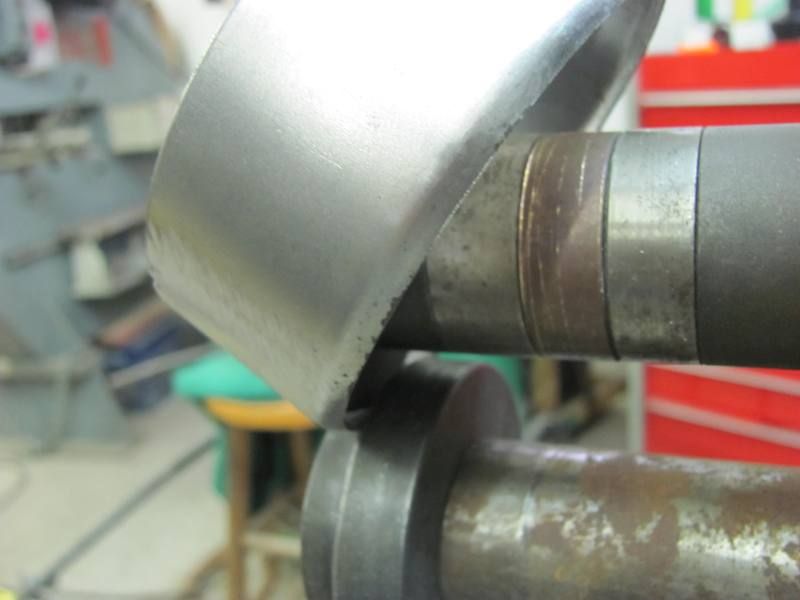

I can make a short step on my bead roller, but that means I have to have every die they make and it probably won't bend as straight as a brake.

Reply With Quote

Reply With Quote