This thread will document the repairs for a handyman wagon tailgate, but the process should be similar/adaptable for a Nomad tailgate as well.

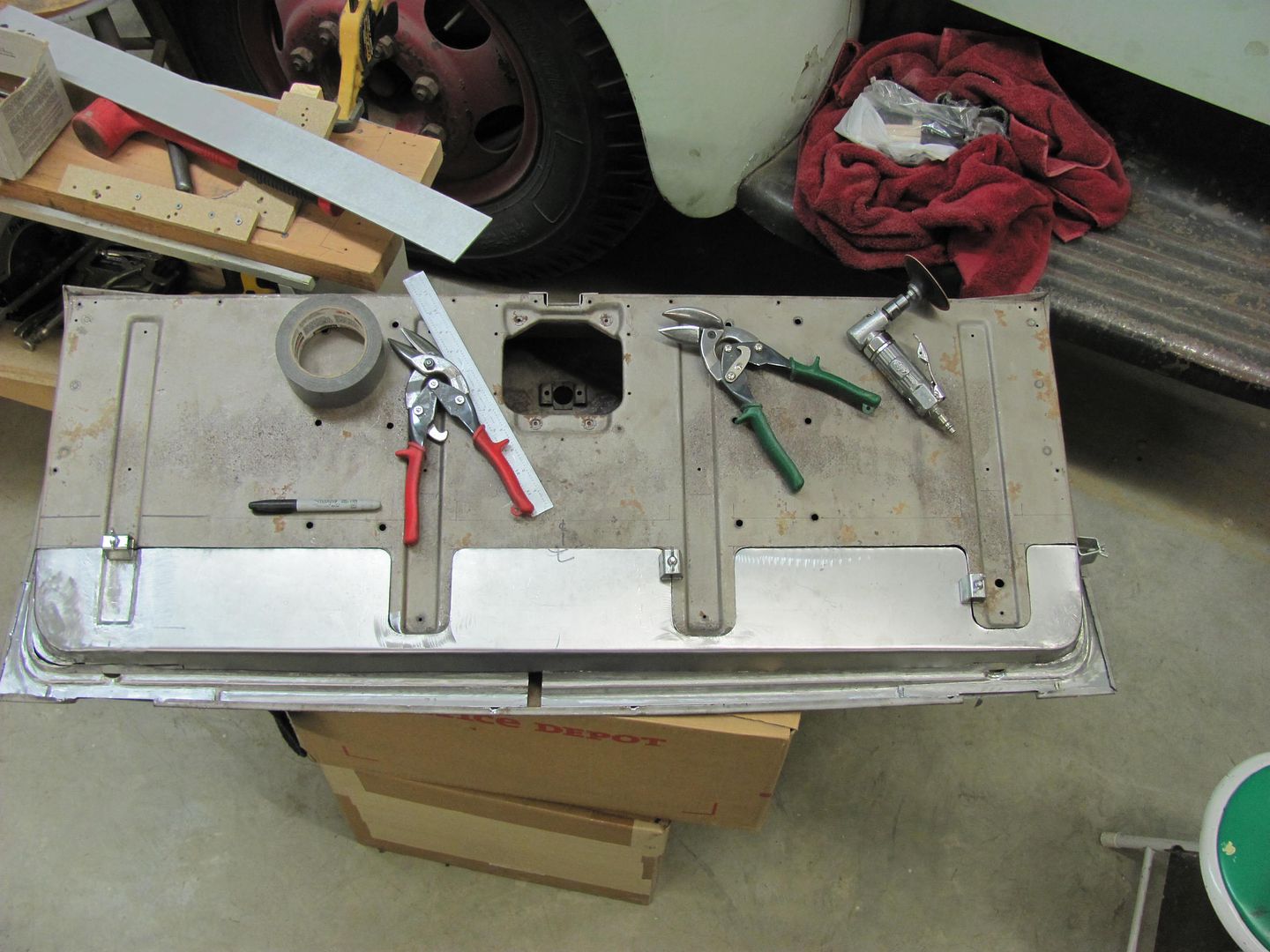

Time for dissecting the wagons tail gate. The outer skin looked fairly decent for 55 year old metal, only a couple pin holes showing....

The major issue with these tail gates, due to how they lean forward, any water collecting inside lays in the inner panel....

.......as you can see from the back side....

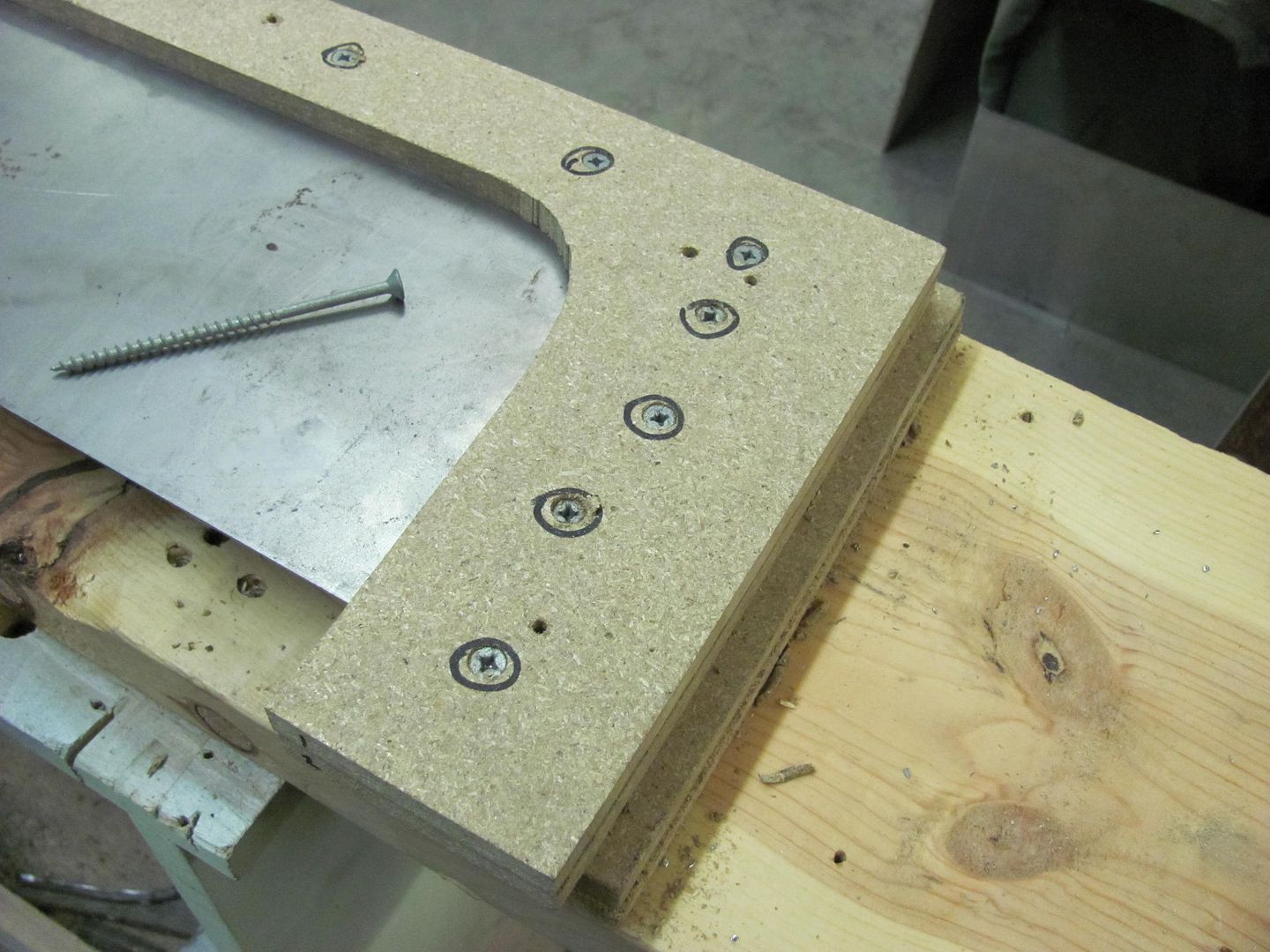

We laid out the proposed cut lines, used holes in the inside corners to add a radius, and made some sparks...

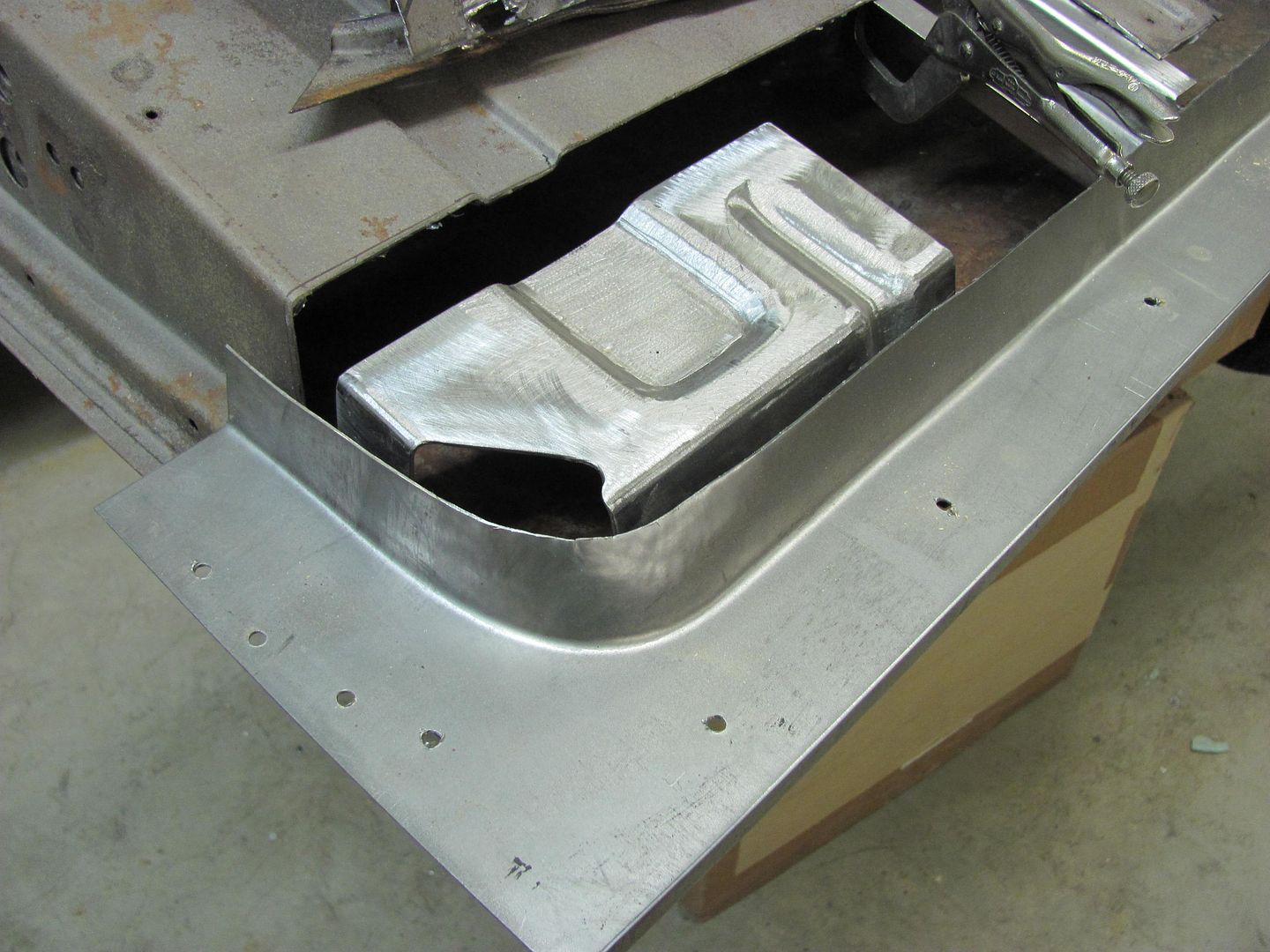

The tailgate has some internal stiffeners to help support the loading and unloading, and they have suffered some damage as well....

Since they're just spot welded in, and it will be easier to weld in newly fabricated ones than attempt repairs of the rusty ones in place......

We'll need to unfold some flanges to remove the rest of the inner panel....

Reply With Quote

Reply With Quote