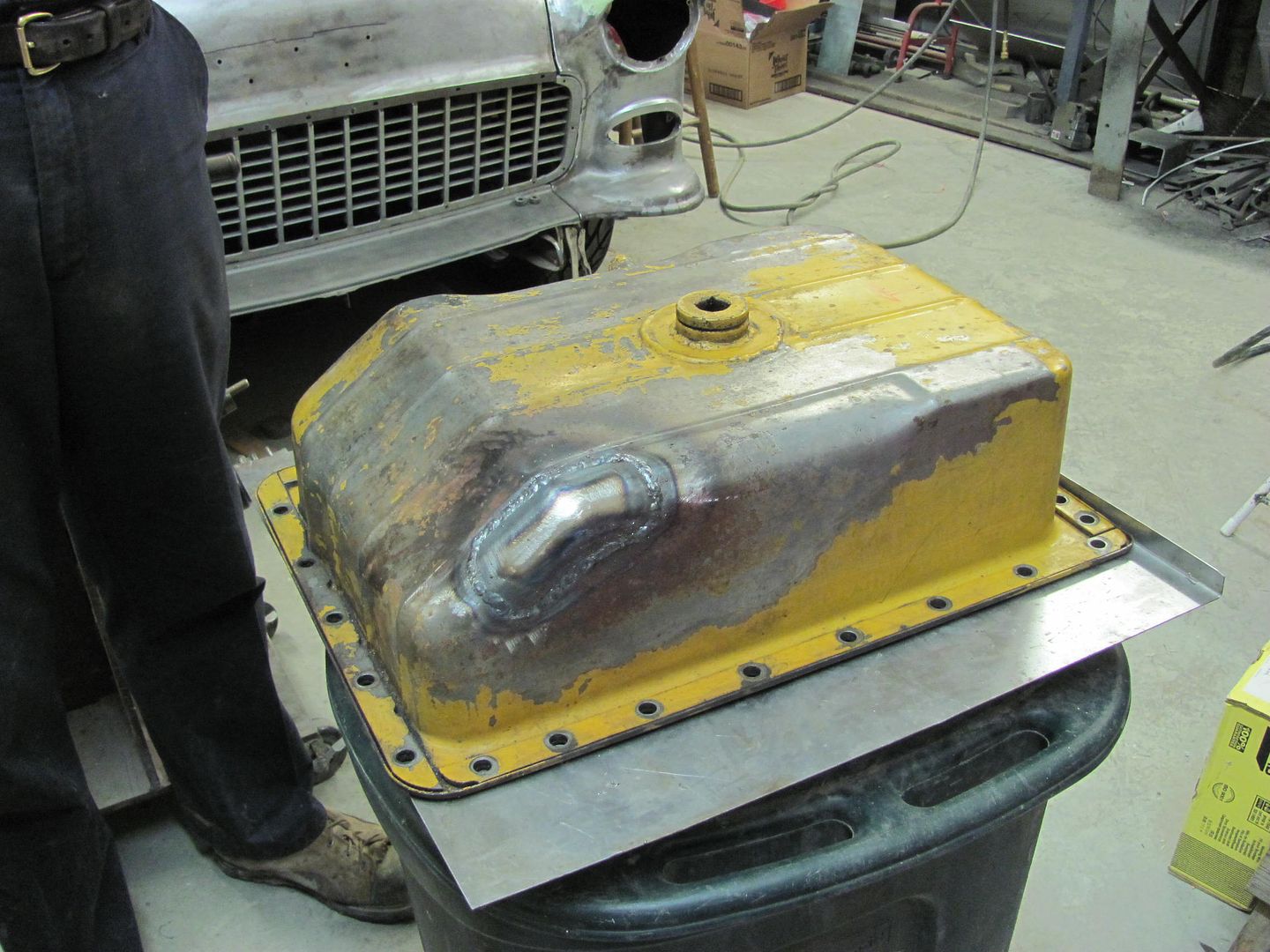

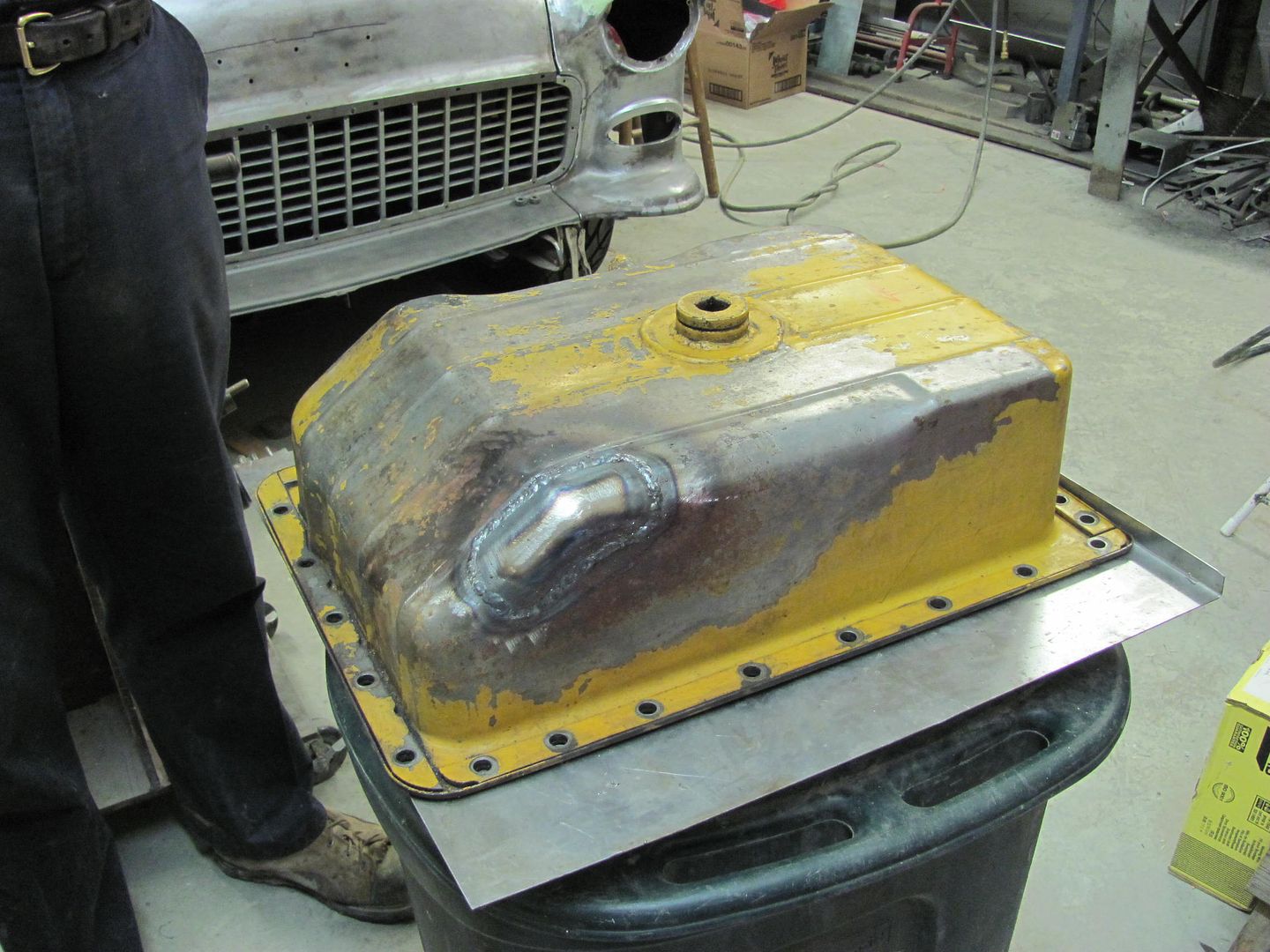

So today I got a phone call, and long story short, needed to do some metalshaping for a Caterpillar D5 dozer. No, really! The last time this same mishap occurred was over ten years ago in my back yard. It seems dirt/mud gets packed between the stump pan and the oil pan, until a hole rusts through the oil pan. Last time Paul bought a new oil pan, but it sounded like he needed to use the dozer this week, so he brought it over for repair..

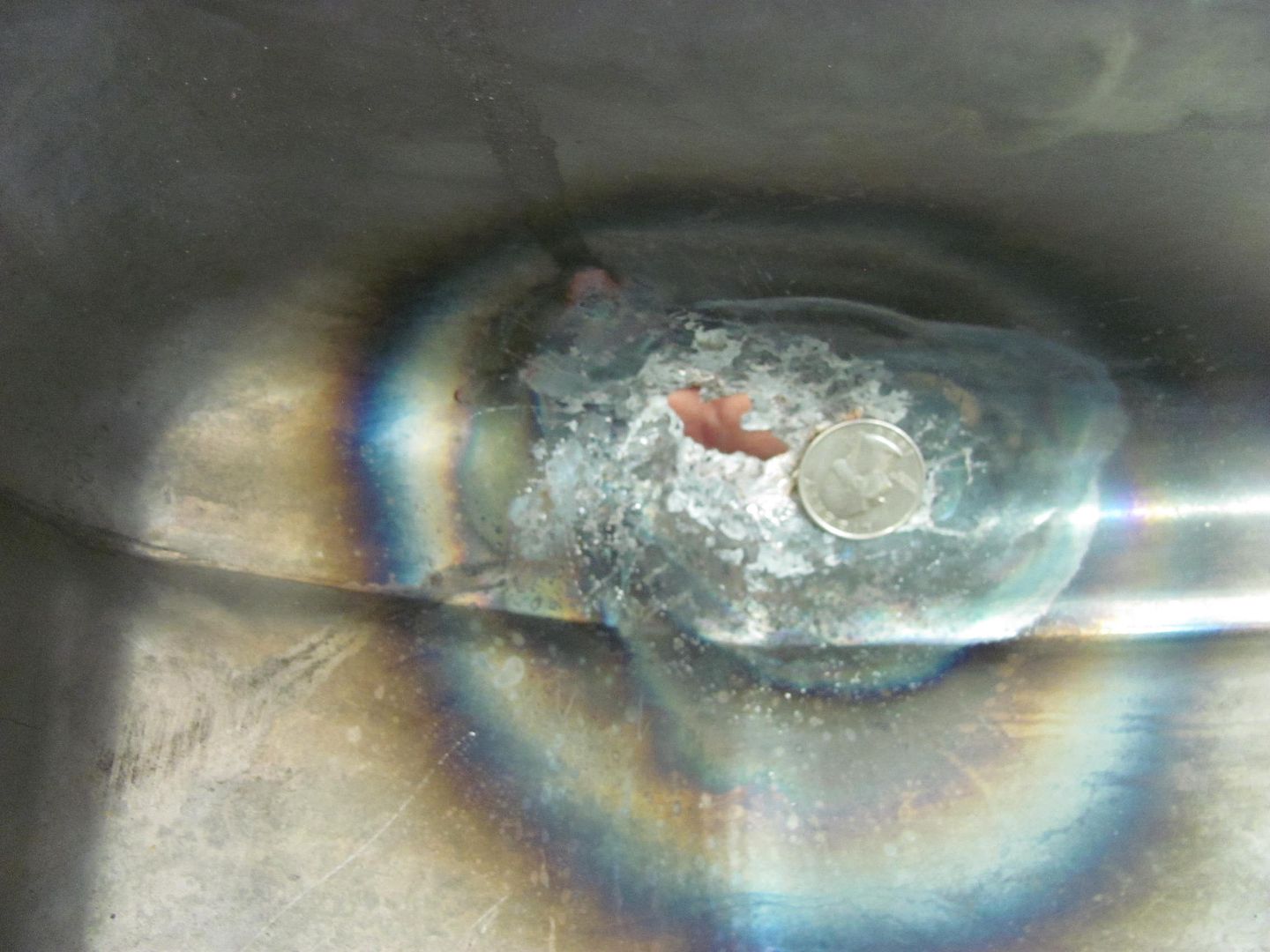

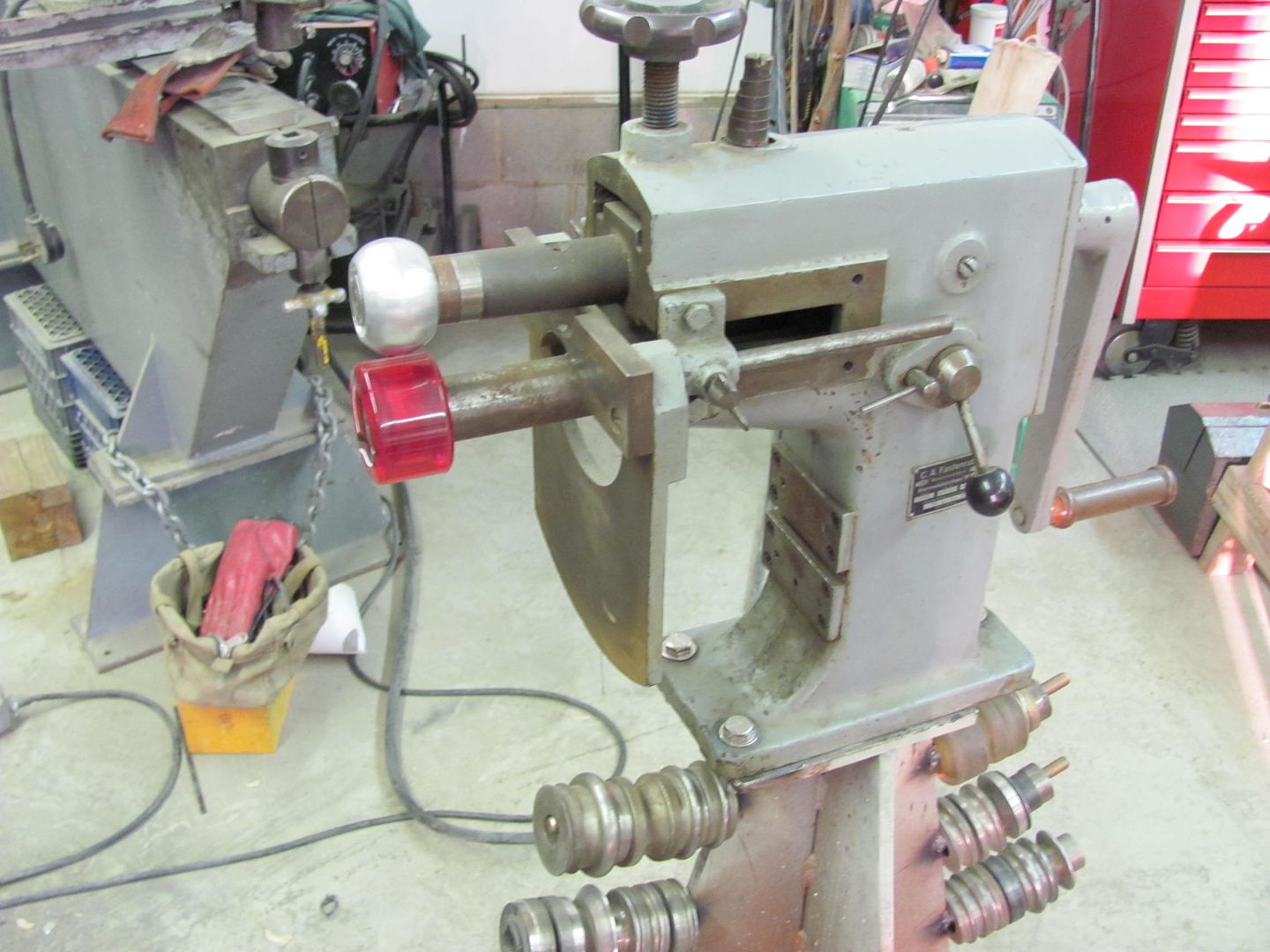

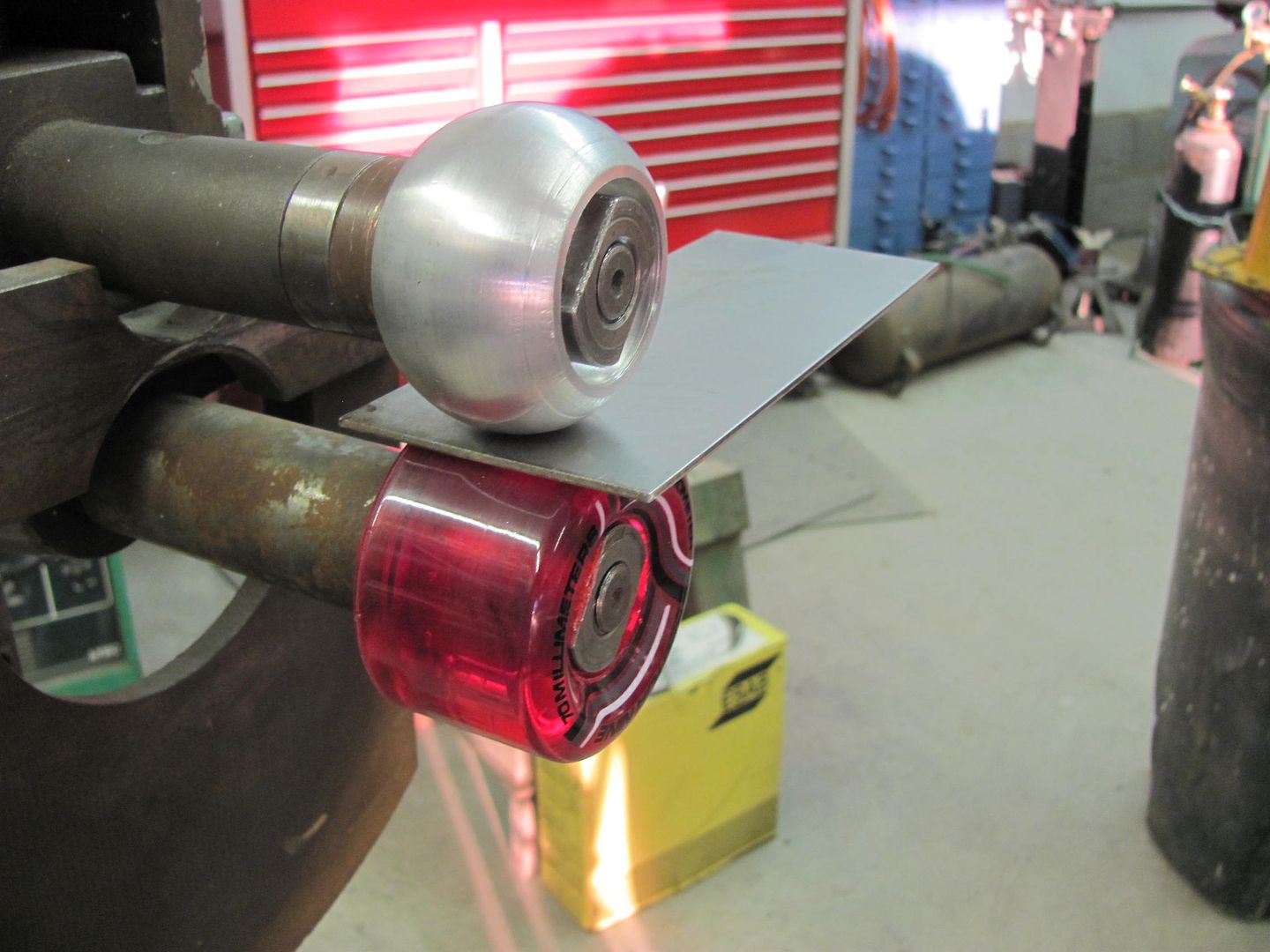

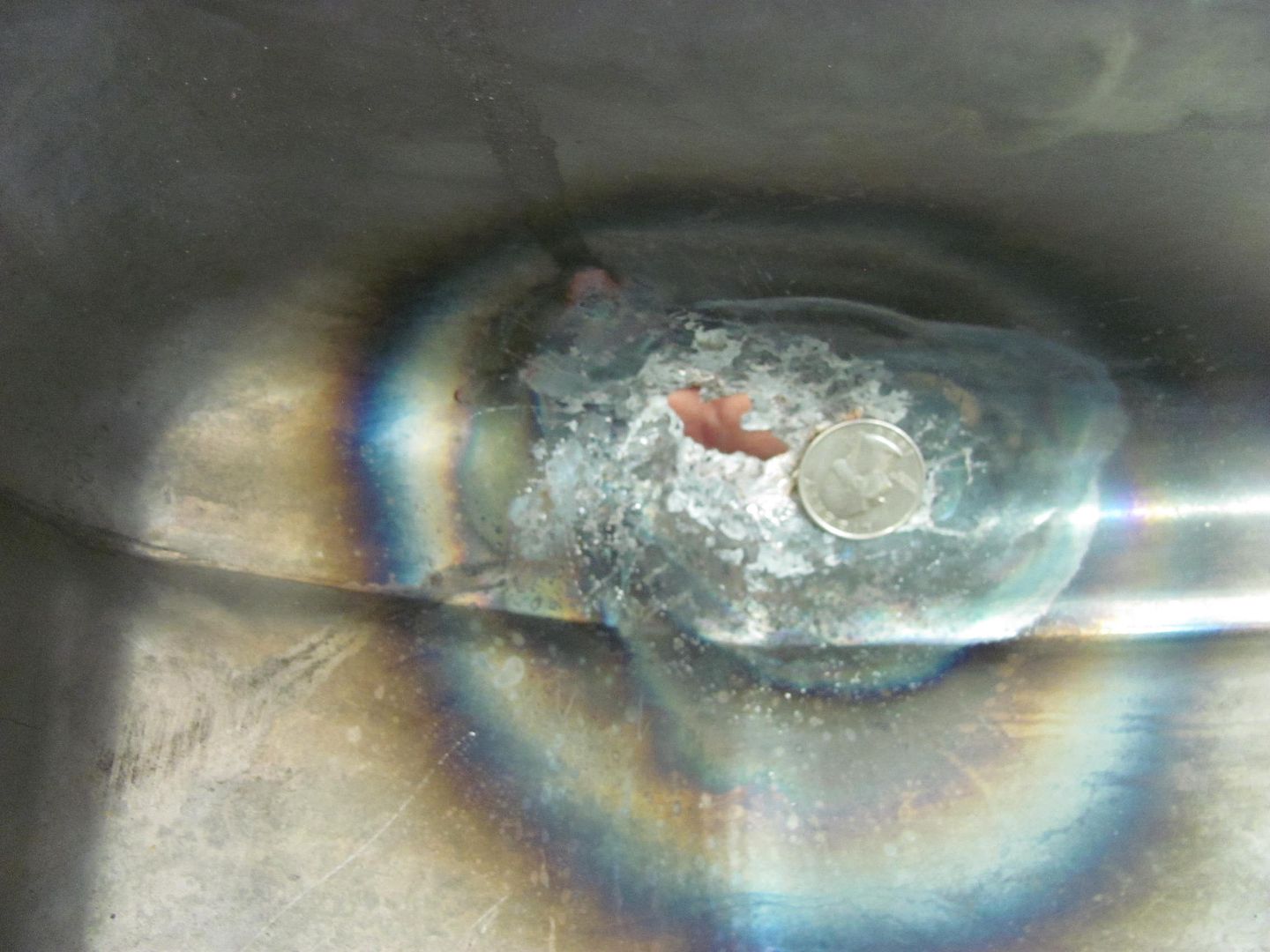

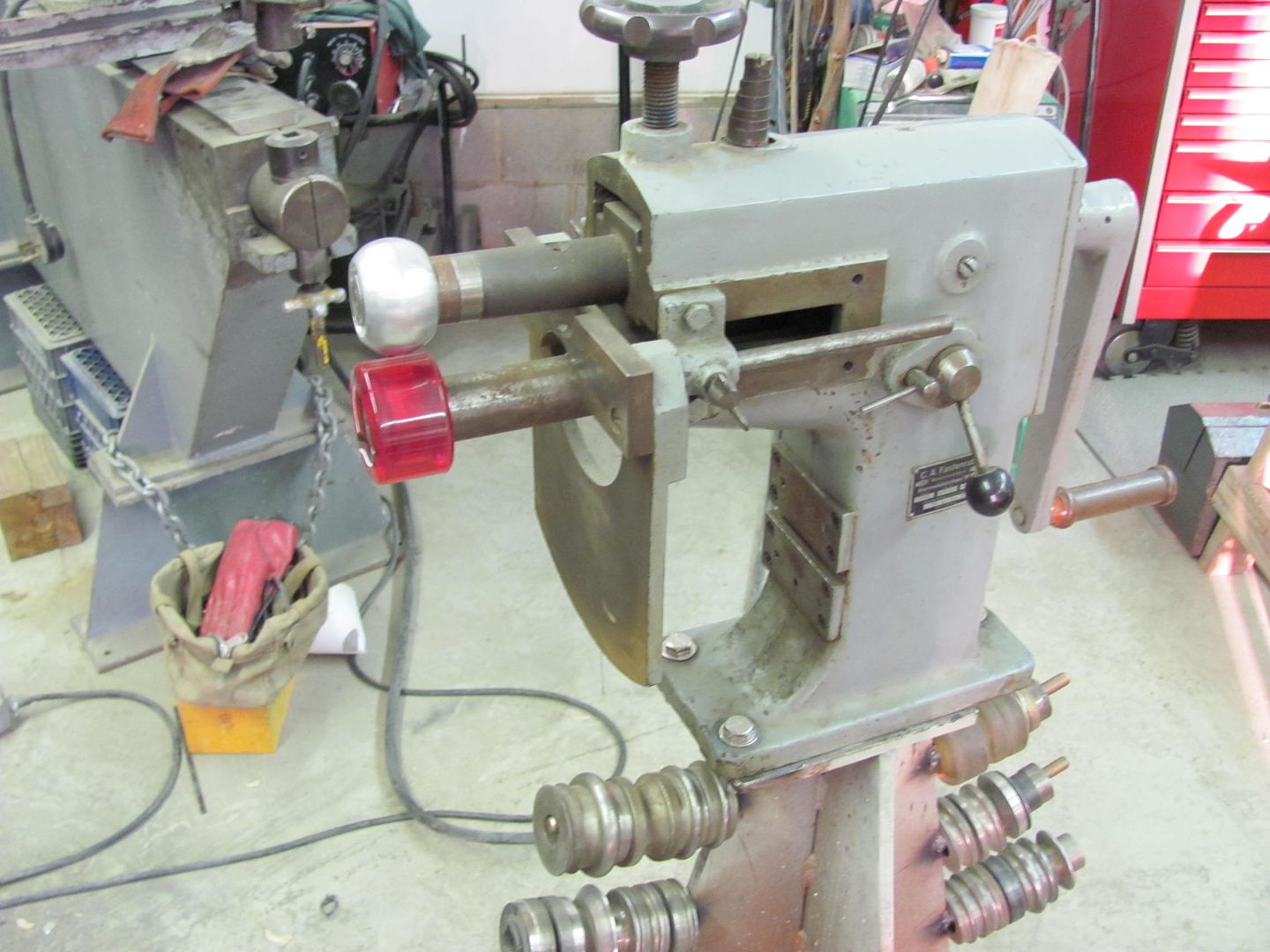

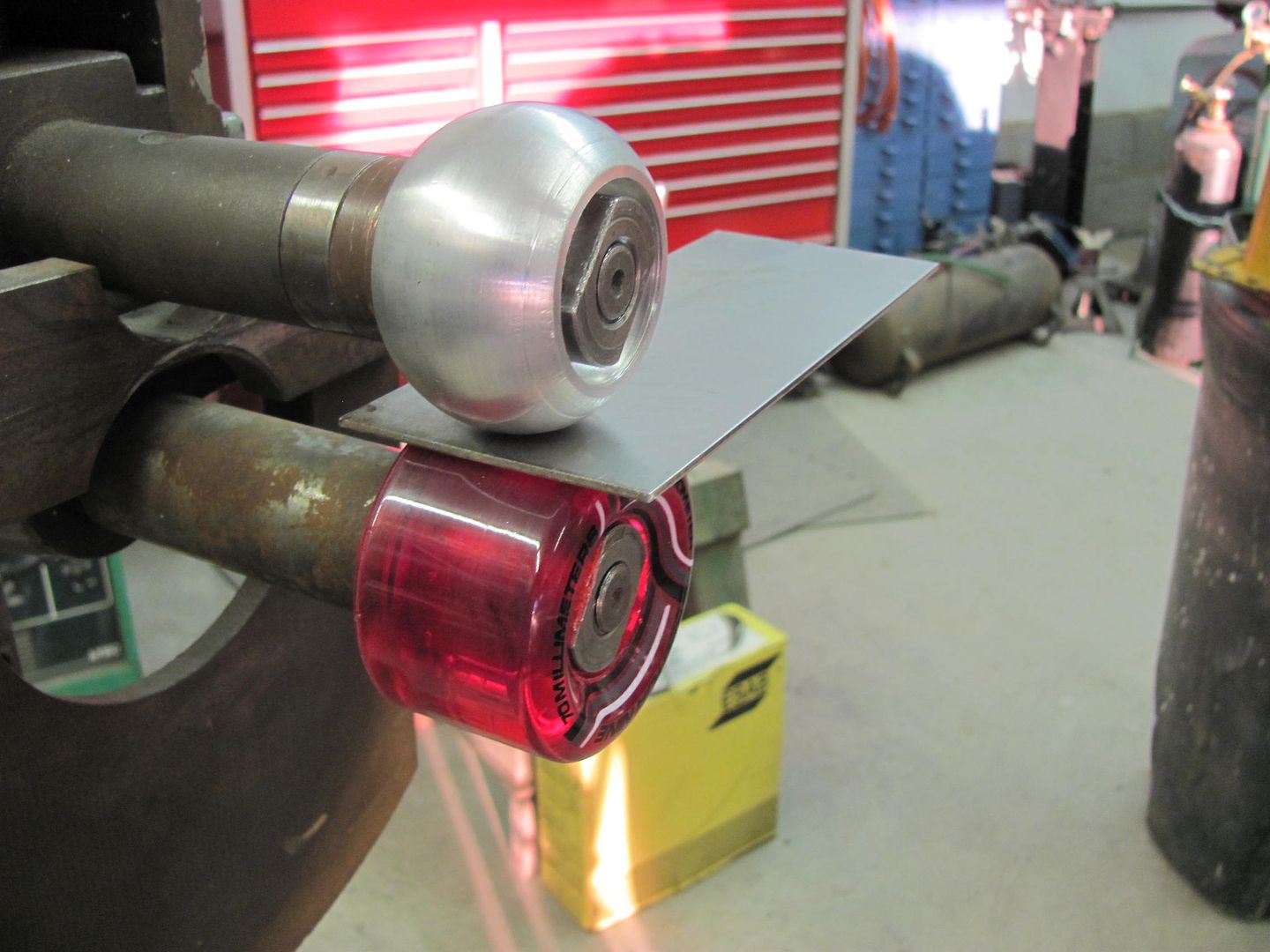

The heat marking is where he was attempting to braze it closed, with little success. Calipers showed the pan to be 14 ga, and I just happened to have some in stock. I've used the bead roller before to form a radius, but never on metal this thick before. This will be a good test of the fancy 75A durometer skateboard wheel to see how well it works.

Took a few passes, but worked real nice. Now for a relief cut and a weld...

Rust hole removed, patch trimmed and fitted, then welded in place..

.....and Paul cleans it up for paint..

You never know what you see over here in the shop... :lol_hitti

Reply With Quote

Reply With Quote

Don't you know you're supposed to keep me from doing stupid stuff?

Don't you know you're supposed to keep me from doing stupid stuff?