I was going to get a longer one from McMaster Carr so I wouldn't need to weld them together, but thanks!

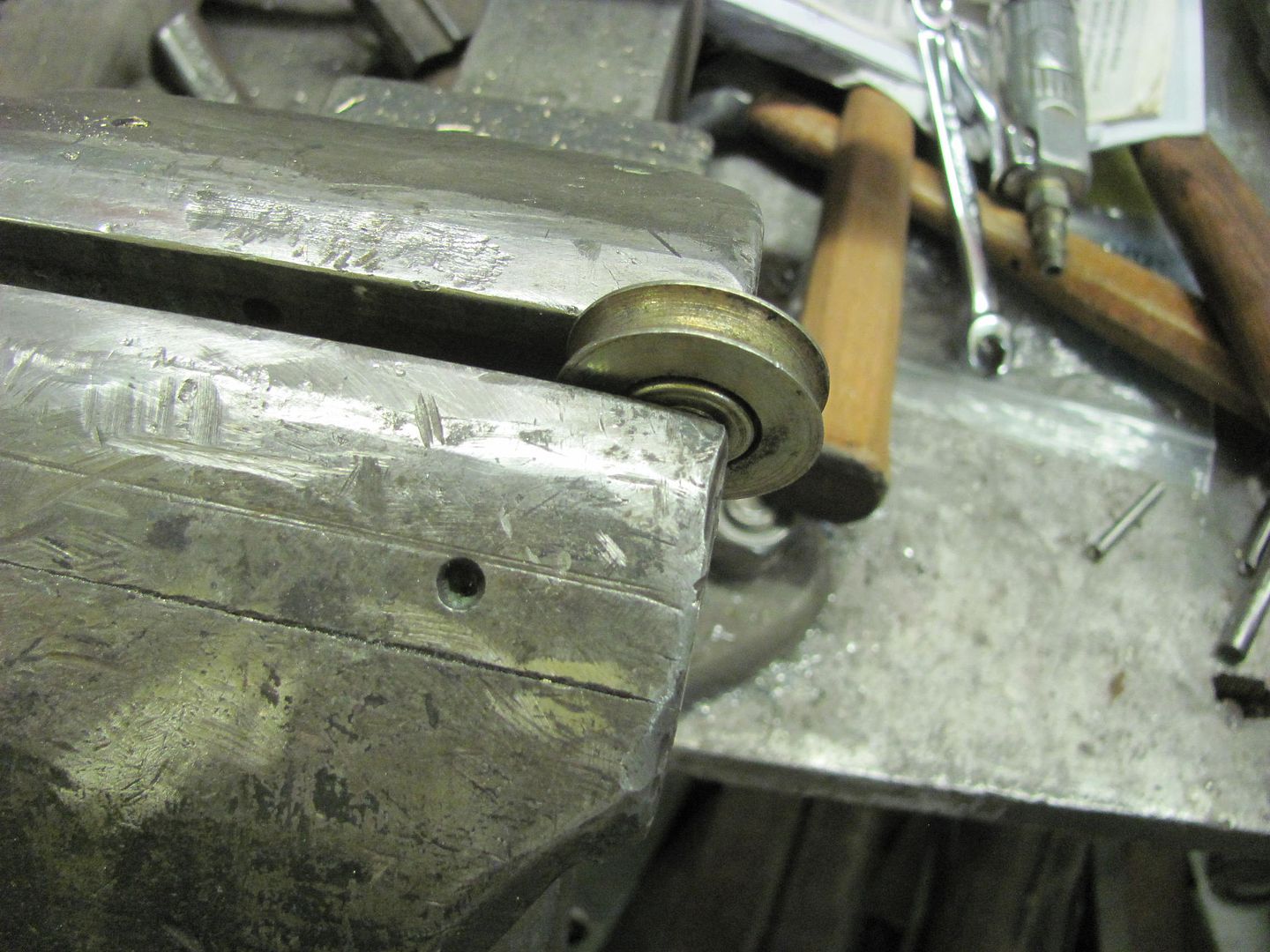

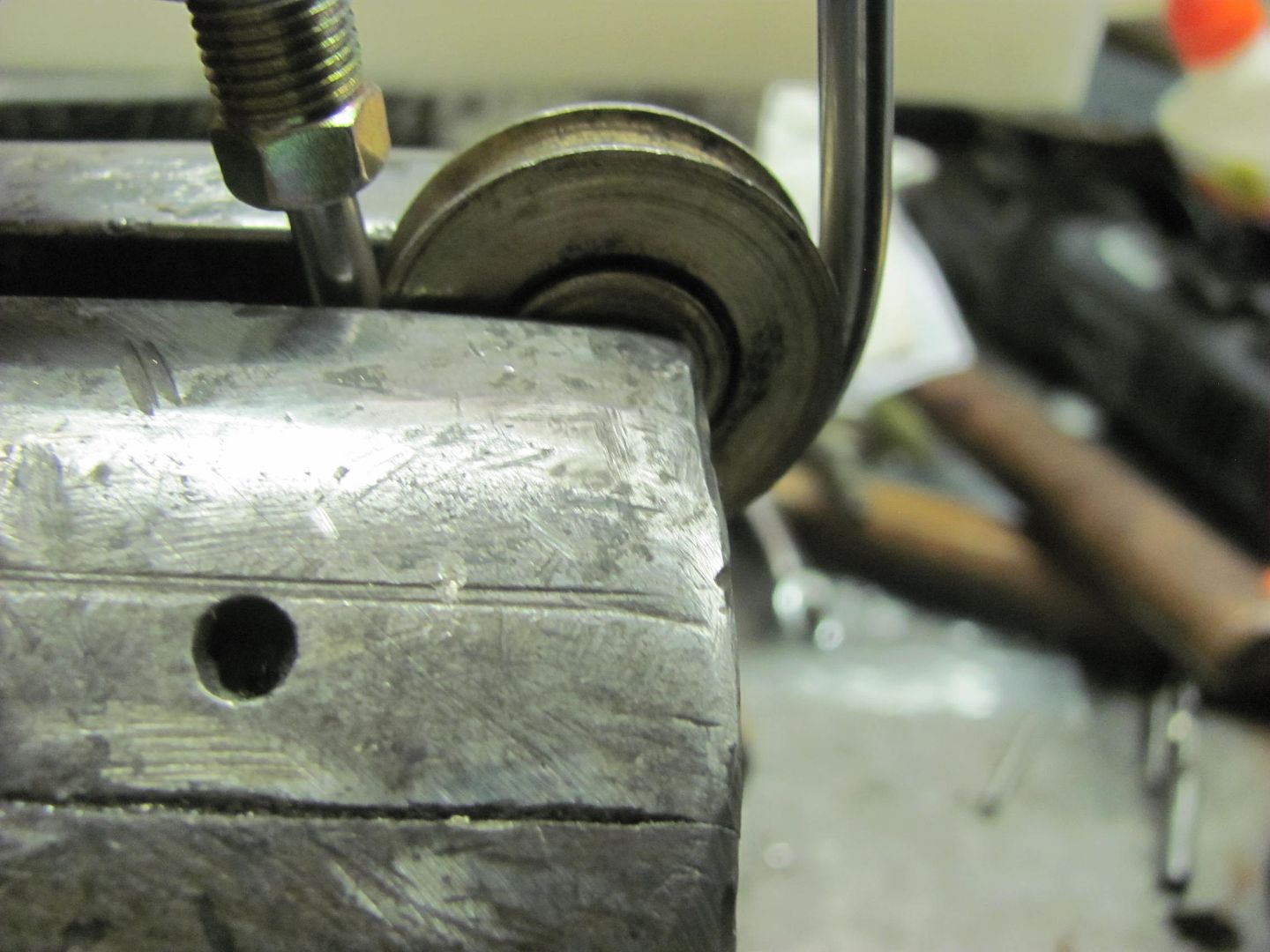

Spent some time in the shop tonight finishing the other weld but I was on a

roll and forgot the in process pics.. Have to get a new photographer, this one

just isn't working out..

Or the motion picture...

https://youtu.be/SD4j6tJwh7w

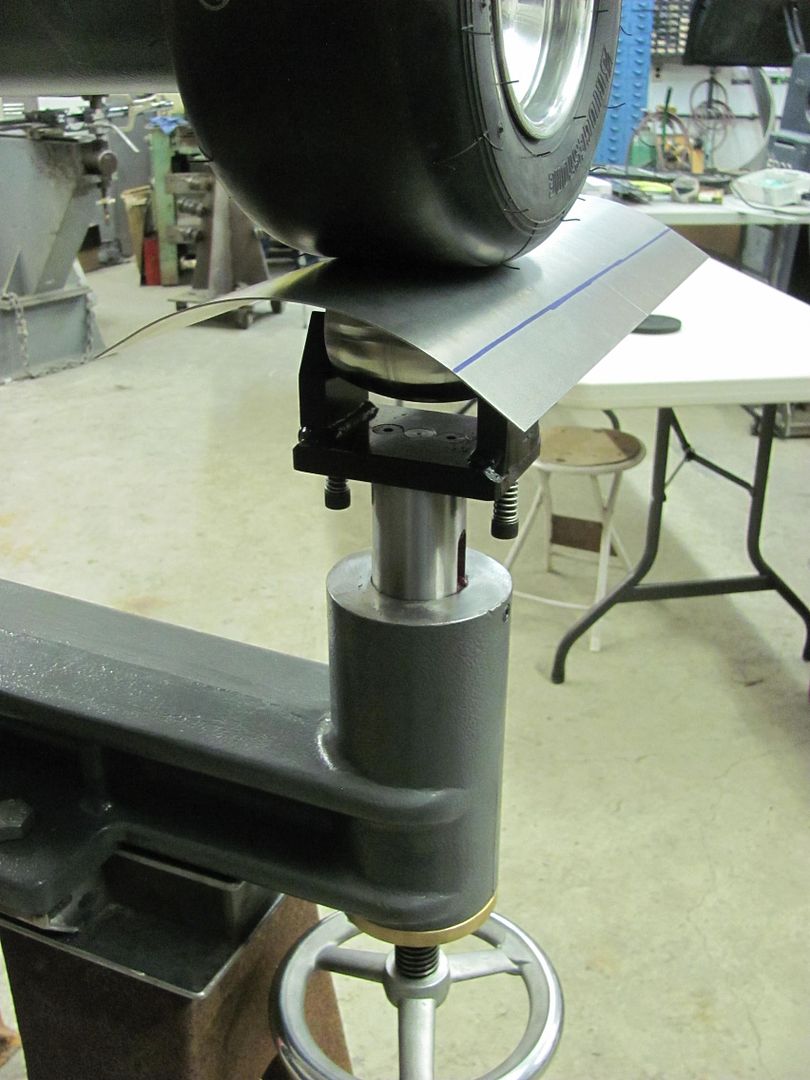

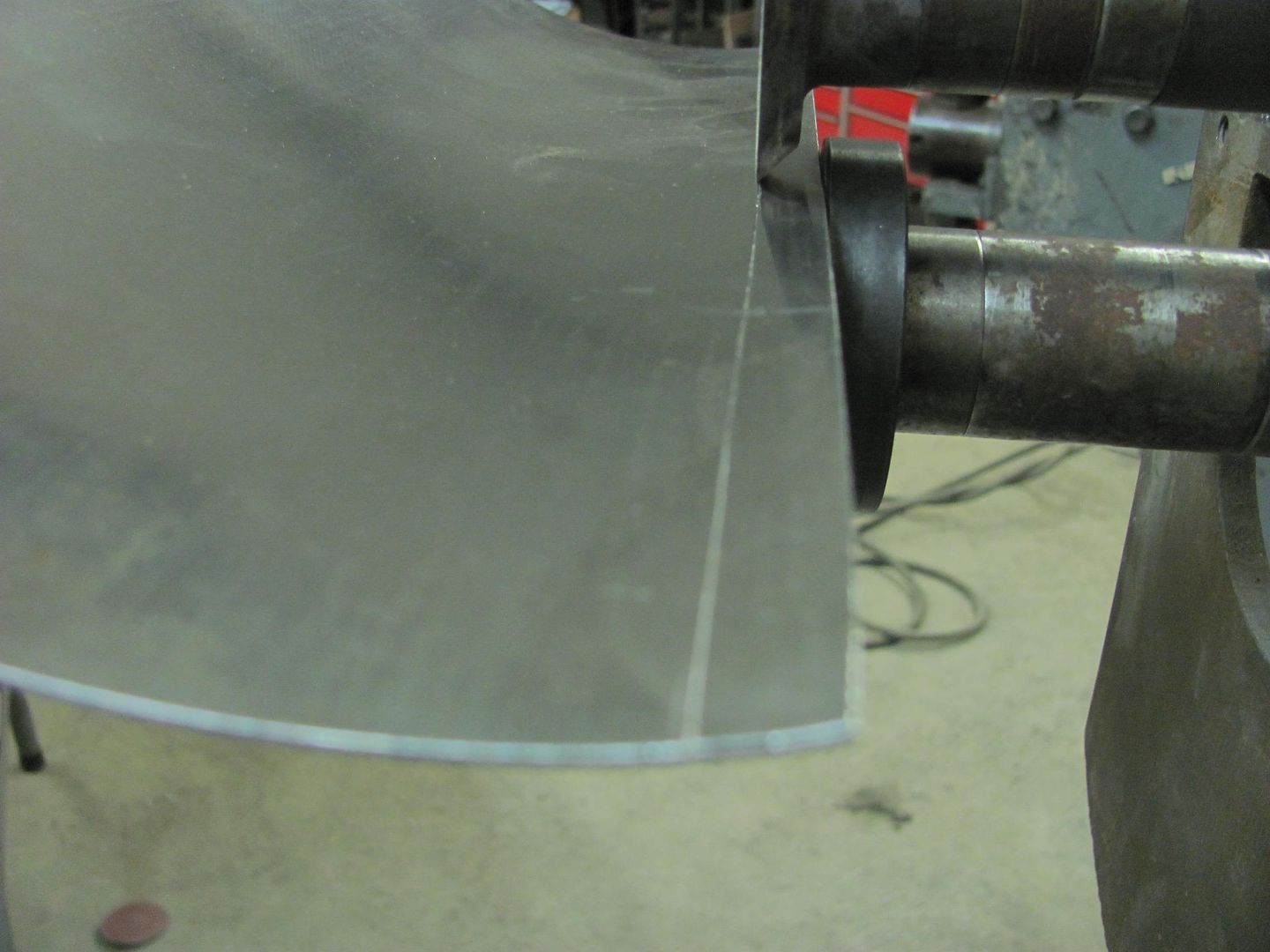

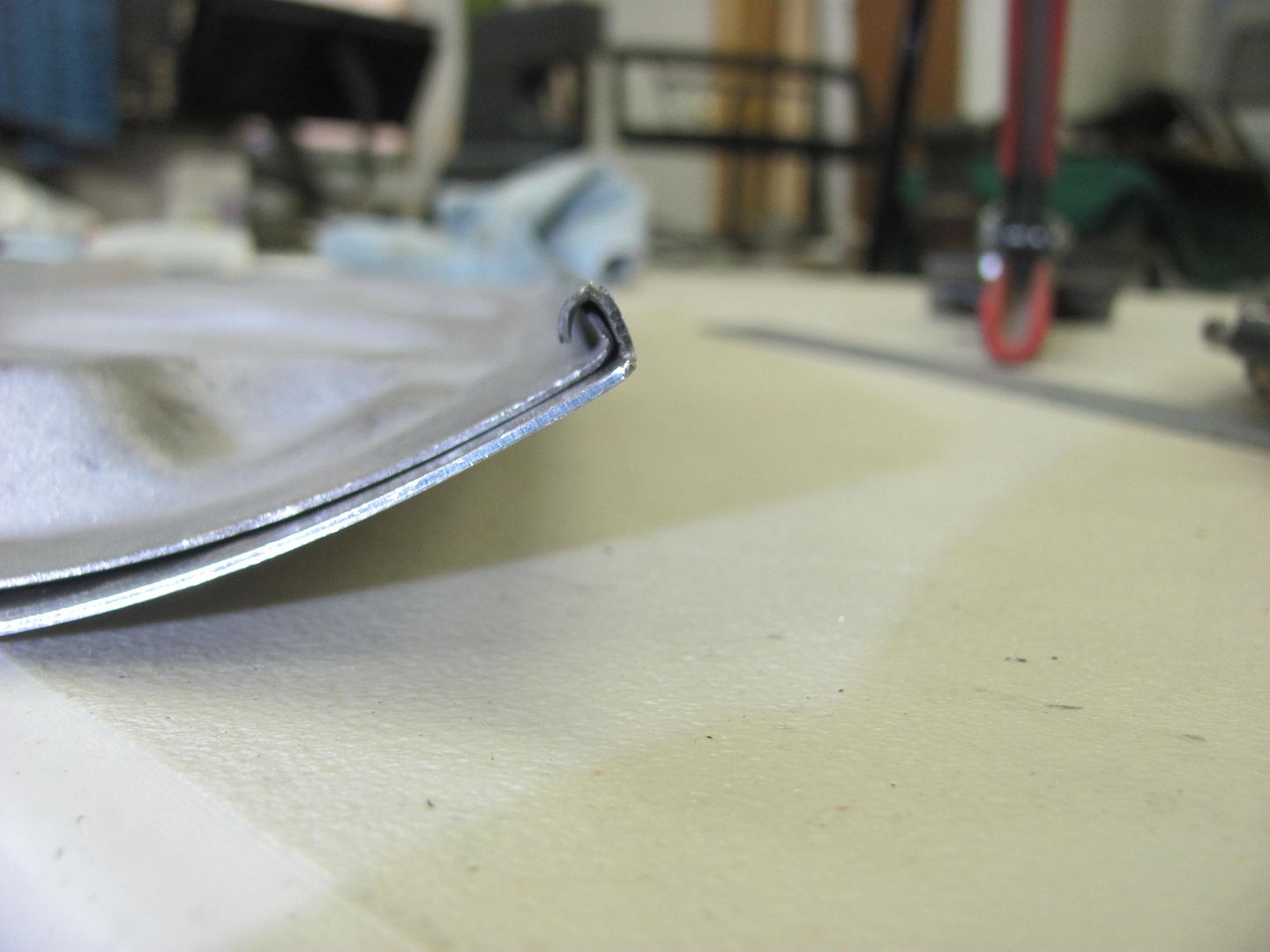

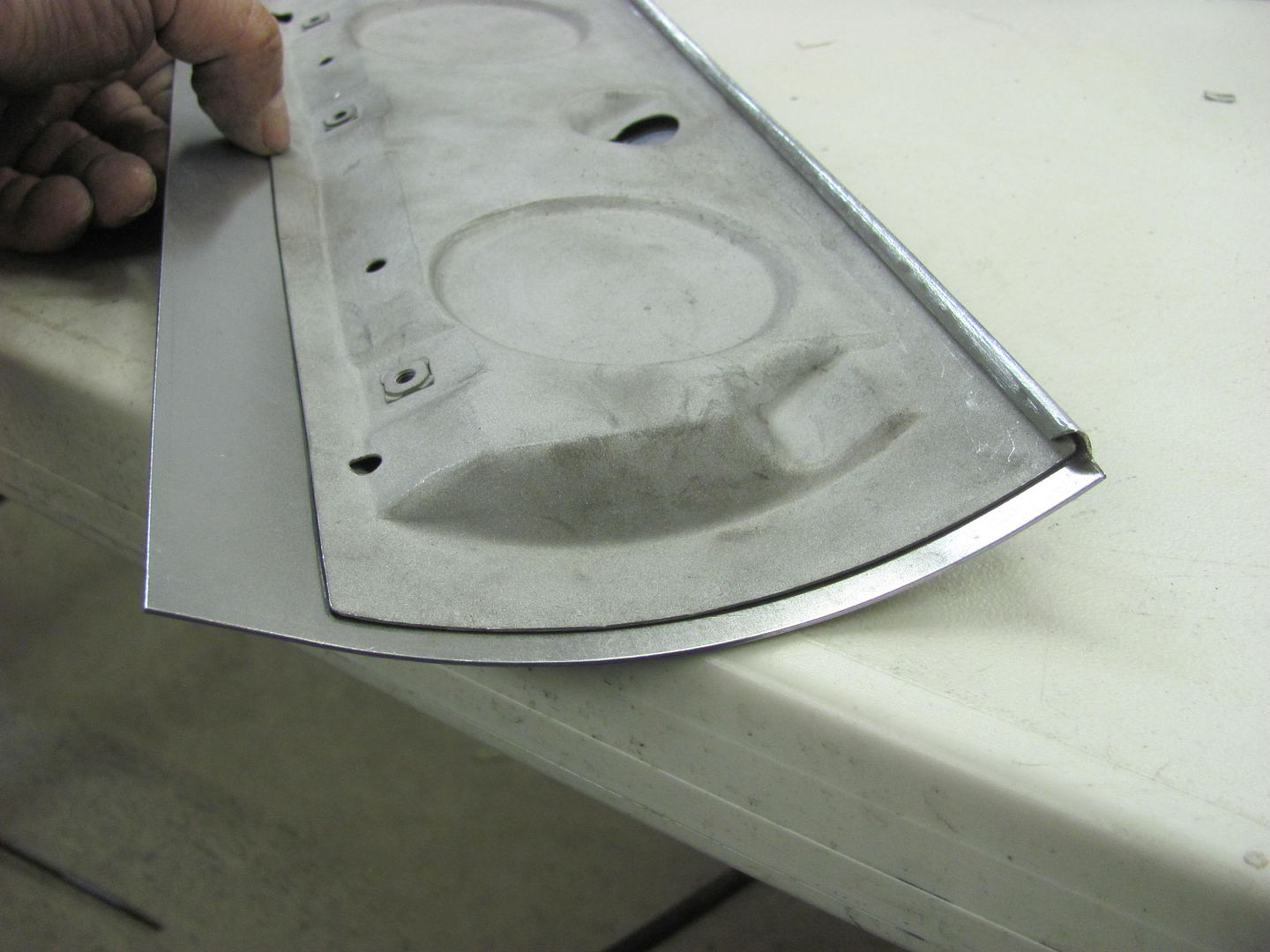

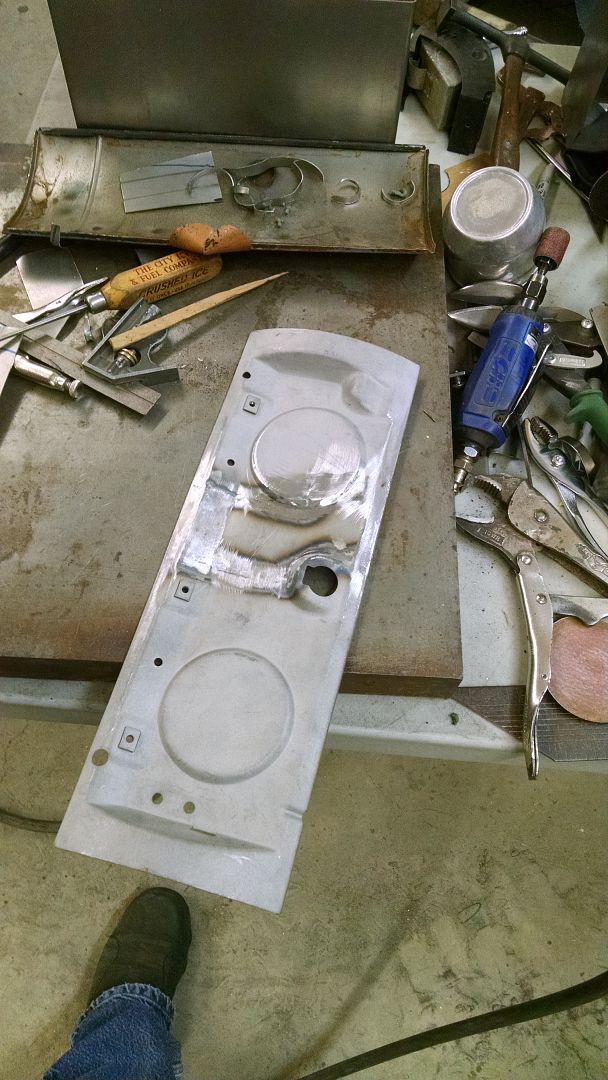

The new Tommasini Wheeling machine is on it's way north from Rock Hill SC,

we'll be picking it up this weekend. Once it's set up we can whip out the new

glove box door skin..

Reply With Quote

Reply With Quote