Robert, a stock bare frame should weigh about 275 pounds. I don't remember if that's for a seamless or a 2-piece one.

Robert, a stock bare frame should weigh about 275 pounds. I don't remember if that's for a seamless or a 2-piece one.

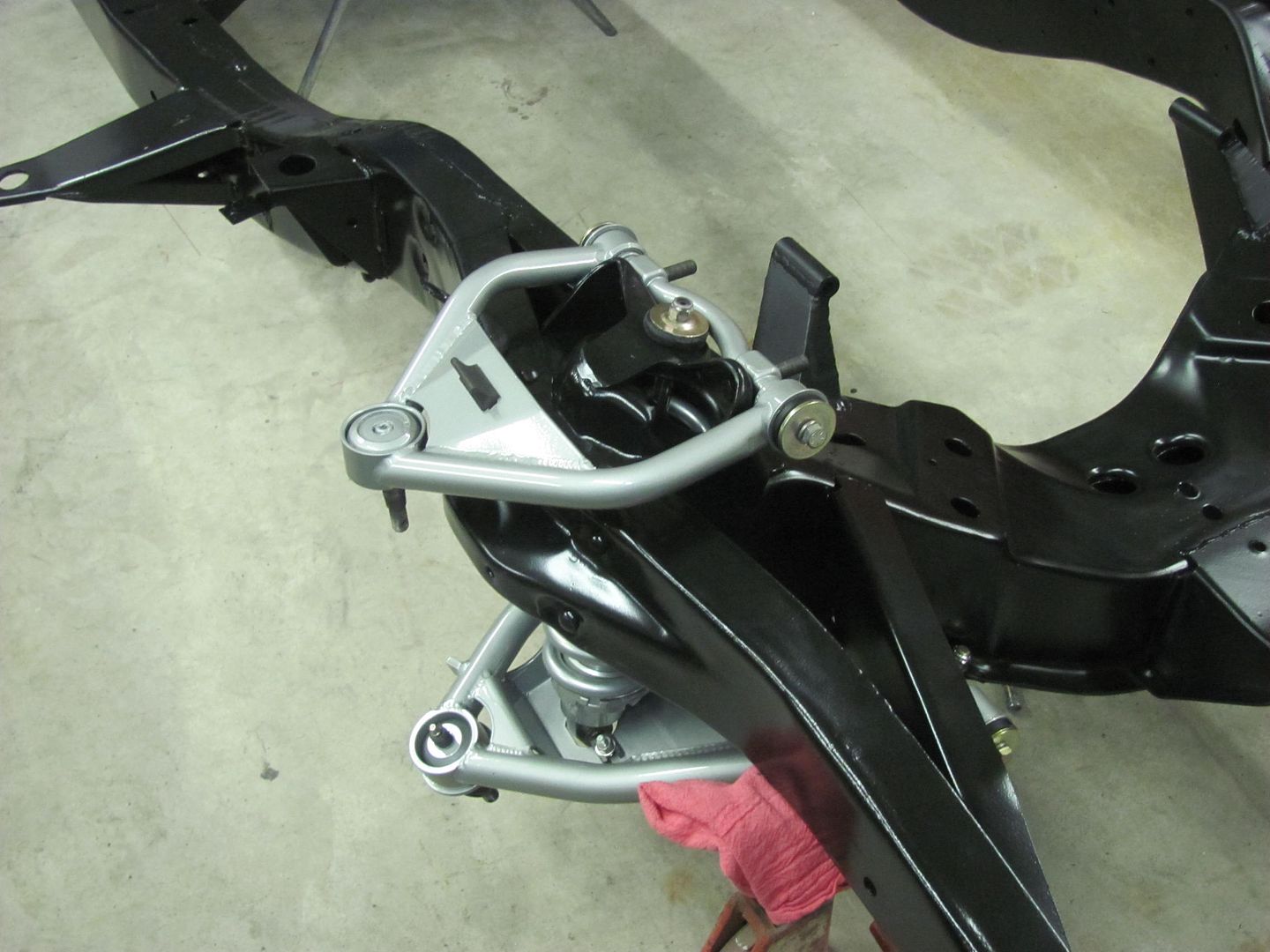

56 Nomad, Ramjet 502, Viper 6-speed T56, C4 Corvette front and rear suspension

Other vehicles:

56 Chevy 2-door BelAir sedan

56 Chevy 210 4-door sedan

57 Chevy 210 4-door sedan

1962 327/340HP Corvette

1961 Willys CJ3B Jeep

2001 Porsche Boxster S

2003 Chevy Silverado 2500 HD Duramax

2019 GMC Sierra Denali Duramax

Thanks, it's a bit muddy here for rolling the rotisserie outside, so trying to figure out how many hard heads it takes to carry it..

Made another trip to the car wash tonight. Tire soak, high pressure soap, and a rinse...

While Kyle was media blasting, I used the 36" AFS to block the tail gate.

This had been blocked a couple times before and never seemed to come out right. Of course, I was using a shorter block as well. The 36 really did the trick in getting things nice and flat...

.....and getting things ready for another epoxy session...

Moved these out of the way, closer to the door so we can get tires on this weekend. Order trim rings today, now for some baby moons that fit... I swear they get brighter every time I look at them..

2 guys can carry a frame...my son and I do it all the time.

Aren't you going to mask the rotors off? Or are you going to have them turned after painting?

I'm doing similar "spray sessions". I'm using a one-step high build primer that my painter uses on all his cars. Just did my differential case and torque arm and brackets. Got everything sanded and ready for the second coat once the diff is assembled. I try to spray as many parts as I can in one session.

Last edited by chevynut; 12-29-2015 at 09:09 PM.

56 Nomad, Ramjet 502, Viper 6-speed T56, C4 Corvette front and rear suspension

Other vehicles:

56 Chevy 2-door BelAir sedan

56 Chevy 210 4-door sedan

57 Chevy 210 4-door sedan

1962 327/340HP Corvette

1961 Willys CJ3B Jeep

2001 Porsche Boxster S

2003 Chevy Silverado 2500 HD Duramax

2019 GMC Sierra Denali Duramax

more worried about good coverage in the fins as they will be visible. We'll clean them up afterwards..

Curious Robert...

Will your paint hold up to the high heat temps those rotors will go thru? Do you use a high temp primer and paint?

1957 Nomad- LS1/T56 on C4 chassis

1959 Fleetside Apache 1/2 ton, shortbed, big window, 327ci.

Just going to spray them with SPI epoxy. We'll see what happens, will be a good test..

Picked up some 400 grit PSA paper yesterday, used it this evening to get the tail gate finished to 400 grit, next week we'll wet sand to 600 grit.

Nephew Chris came over and helped Kyle and I get the frame off the rotisserie and back on the floor..

With the rotisserie freed up, we now have a new paint fixture...

Parts prepped for epoxy primer tomorrow...

While I was getting these parts taped off, Kyle started blowing apart the rear end for media blasting..

Today Kyle worked on getting the axle pads welded on....

.....while I was spraying some SPI epoxy....

.....and while I had some epoxy mixed, we poured some inside the tailgate to

seal the inner and outer skins ..

Axle pads done, then heated the opposite side to counter the weld

shrinking...

It's real close, just a little more straightening to do...

other parts from the booth today....

....and then sprayed some silver metallic Imron on the A-arms..

Well tonight we worked on getting the parts out of the booth so we can get

the next load of parts ready for epoxy, and in between spent some more time on

straightening the rear. In measuring at the bead of the 18" wheels, we had a

+/- .020 on the passenger side and a +/- .035 on the drivers side.

....and more heat applied for some shrink..

We'll let that cool and get some of the front end parts bolted up..

Robert, I guess I'm not understanding why you think a crooked HOUSING will cause wheel runout. Seems to me that the axle itself would have to be bent to do that.

56 Nomad, Ramjet 502, Viper 6-speed T56, C4 Corvette front and rear suspension

Other vehicles:

56 Chevy 2-door BelAir sedan

56 Chevy 210 4-door sedan

57 Chevy 210 4-door sedan

1962 327/340HP Corvette

1961 Willys CJ3B Jeep

2001 Porsche Boxster S

2003 Chevy Silverado 2500 HD Duramax

2019 GMC Sierra Denali Duramax