markm is right, a bent housing doesn't cause runout. An indicator reading will be steady and always off the same amount. A bent axle flange would cause runout, as would a bent wheel.

I don't think a bent housing would cause a significantly increased bearing load. The extra load would be taken by the other end of the axle, but there is already a significant load there and it wouldn't change much.

This is with fractional degrees of error. The Nascar cars use a special arrangement of a full floating hub to allow several degrees of camber. Those parts have to be really strong to avoid breakage. They are also subject to the extra loading of banked tracks and of 900 hp x 4 corners x 500 laps or miles.

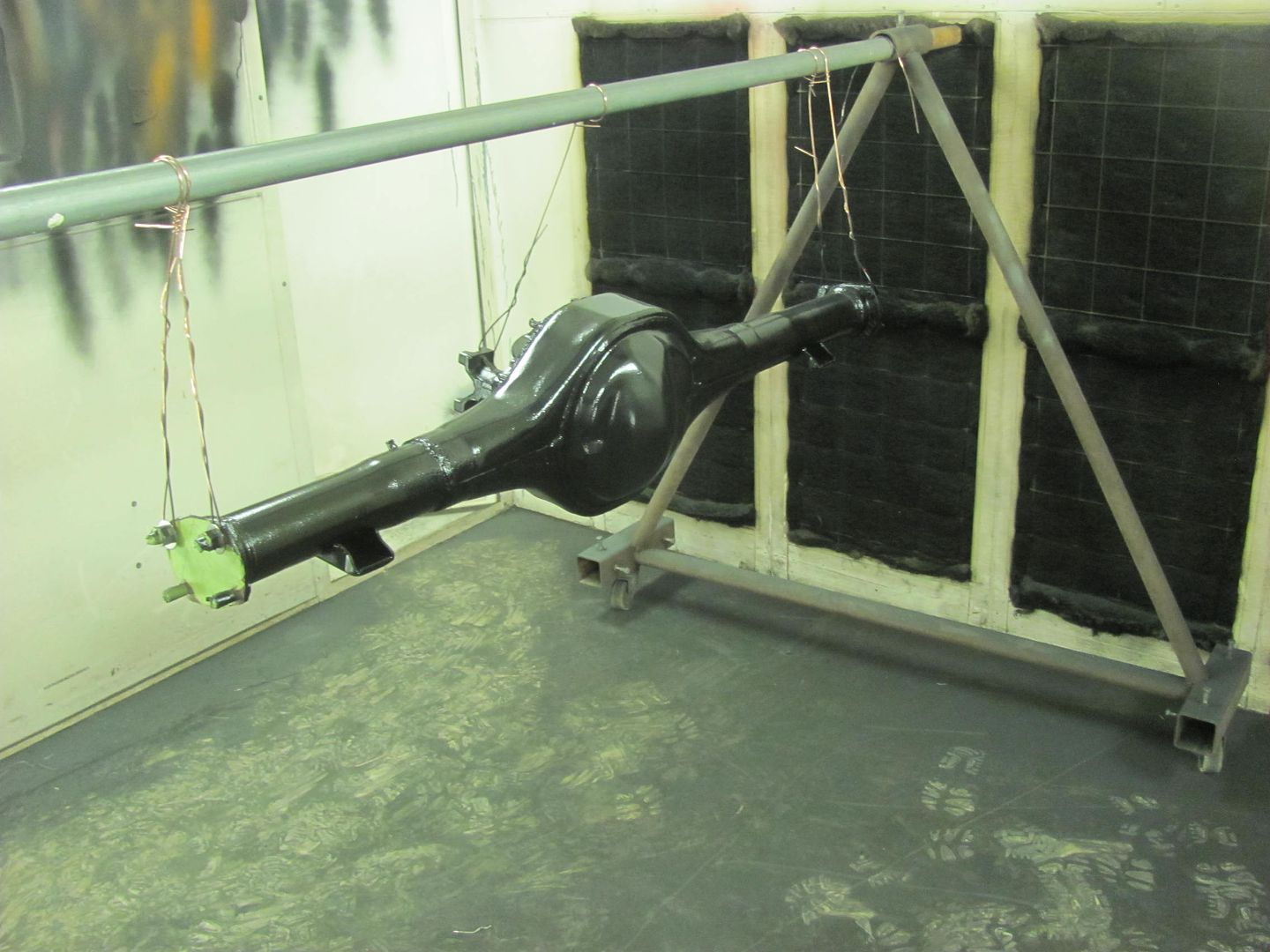

Some drag race and more often circle track cars have intentionally bent housings for camber and toe in - sometimes to get neutral under load, sometimes to induce desired toe or camber.

Reply With Quote

Reply With Quote