Well in our typical back up and punt fashion, the original battery hold downs that we had already powder coated did not fit the battery, too short. So we ordered some round stock in stainless to fabricate some new ones.

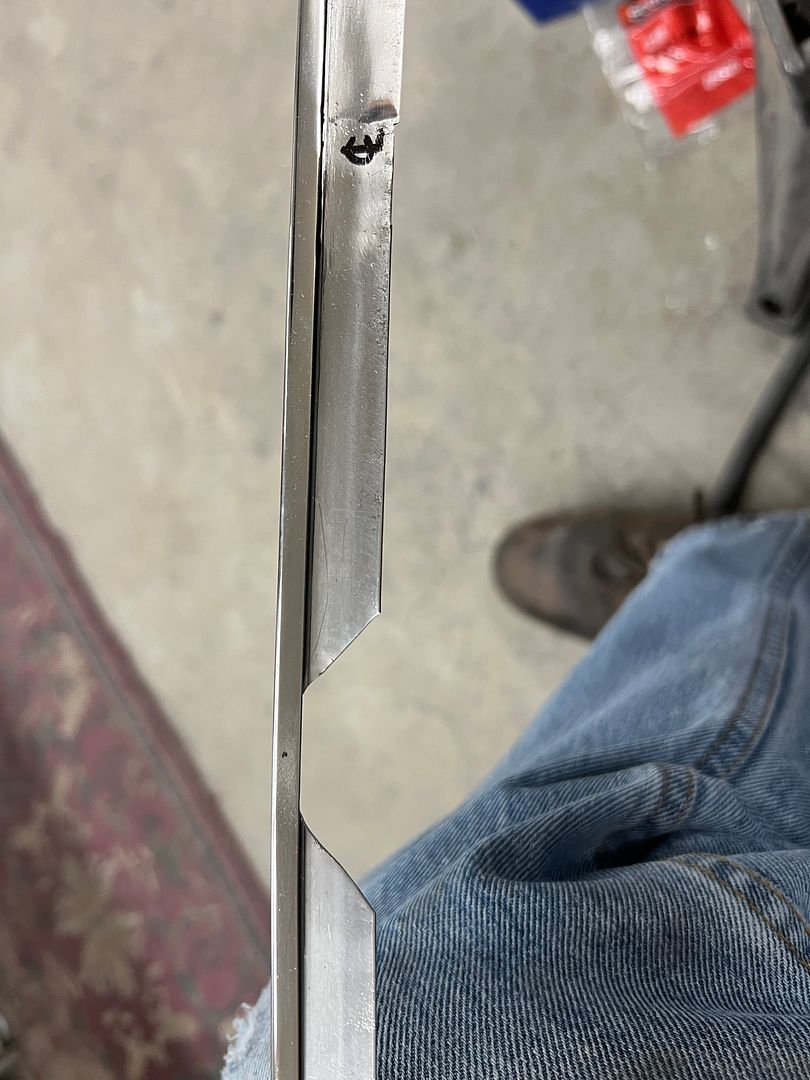

A threaded standoff was modified to provide an angled surface for using as a hammer form to get the bottom "hooks" consistent...

All polished up...

Installed, and no polish job is complete without addressing the ends of the rods..

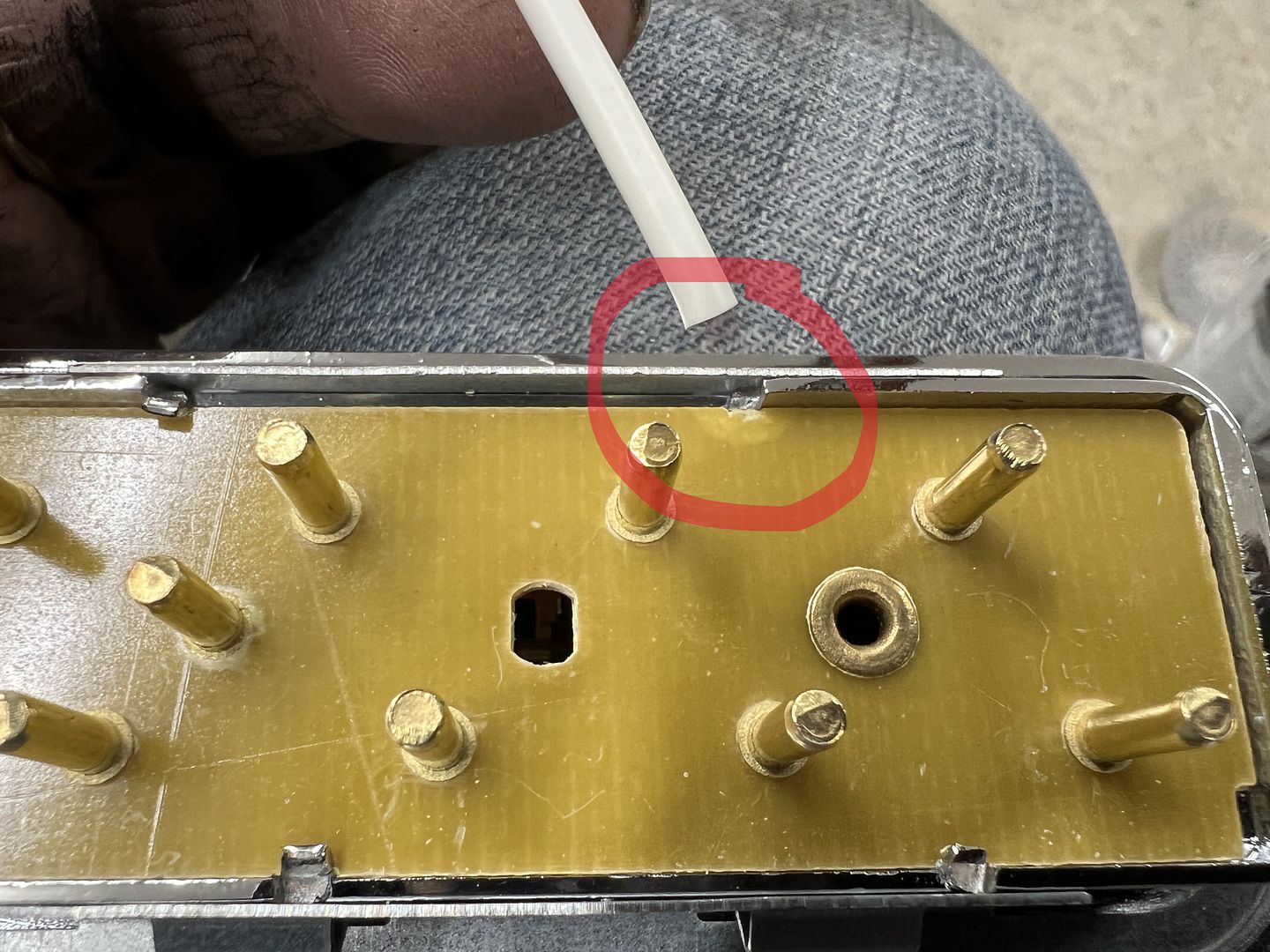

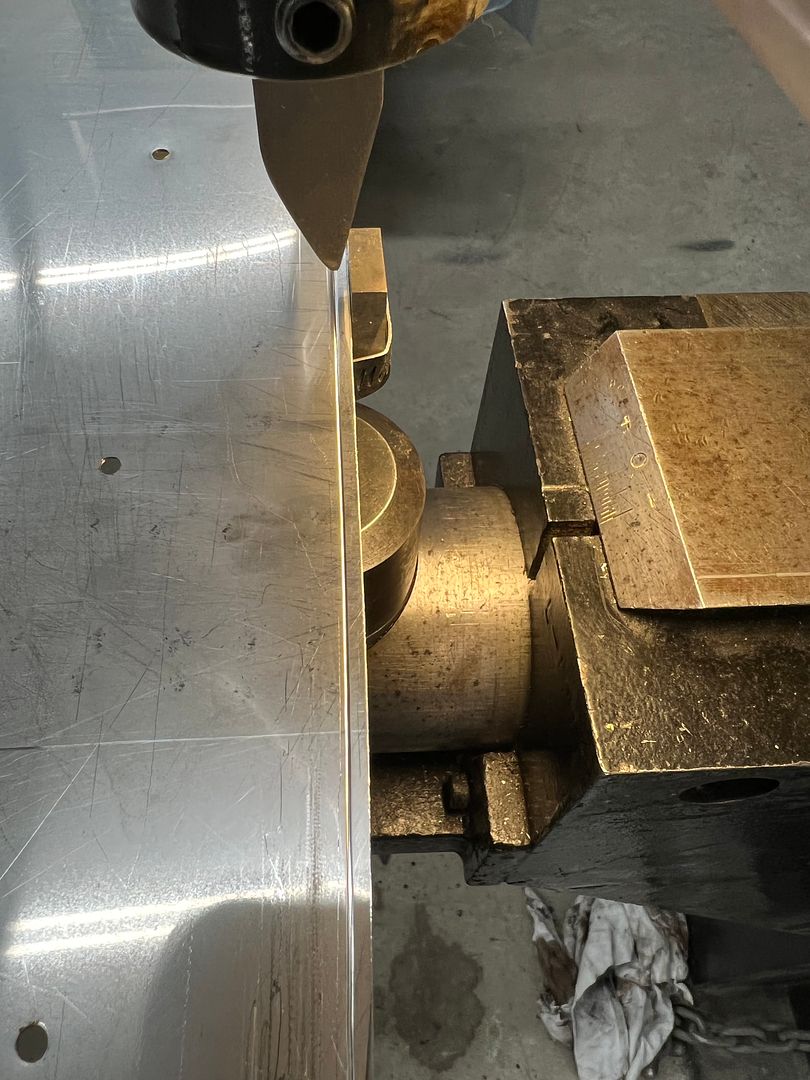

Assembling our vent windows, the excess rubber is trimmed using a No. 11 scalpel blade for a nice and tidy fit

All the bits assembled

installed...

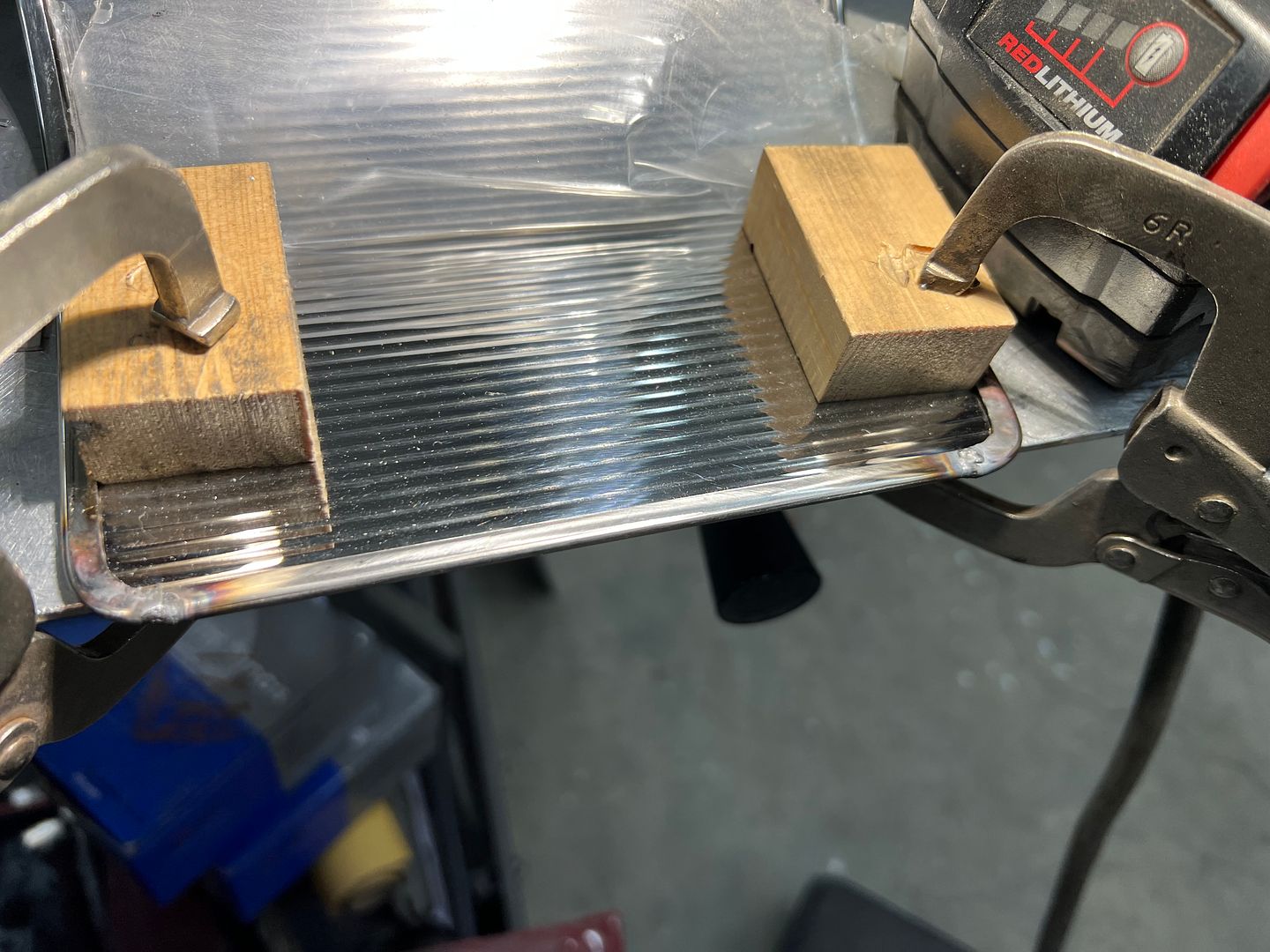

And more stainless we missed, the parting bands for the front arm rests, complete with a form-fitted sanding/polishing fixture

A threaded standoff was modified to provide an angled surface for using as a hammer form to get the bottom "hooks" consistent...

All polished up...

Installed, and no polish job is complete without addressing the ends of the rods..

Assembling our vent windows, the excess rubber is trimmed using a No. 11 scalpel blade for a nice and tidy fit

All the bits assembled

installed...

And more stainless we missed, the parting bands for the front arm rests, complete with a form-fitted sanding/polishing fixture

_IMG_8985.png)

Comment